Automatic capping machines

Processing machines

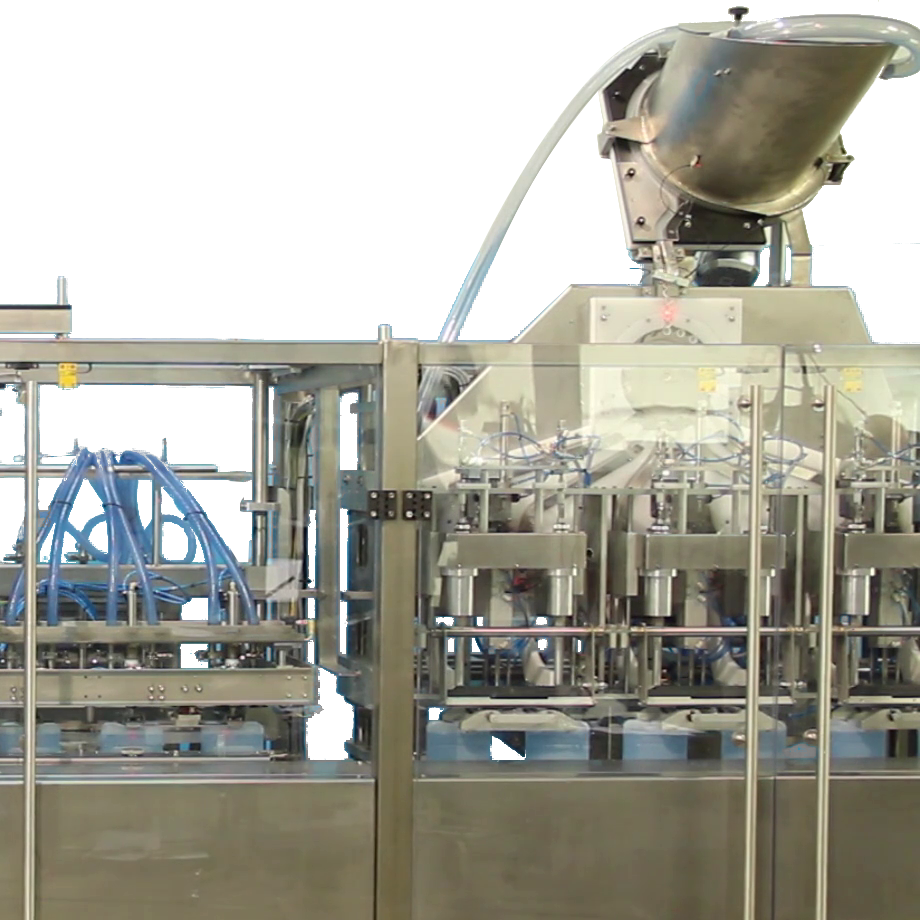

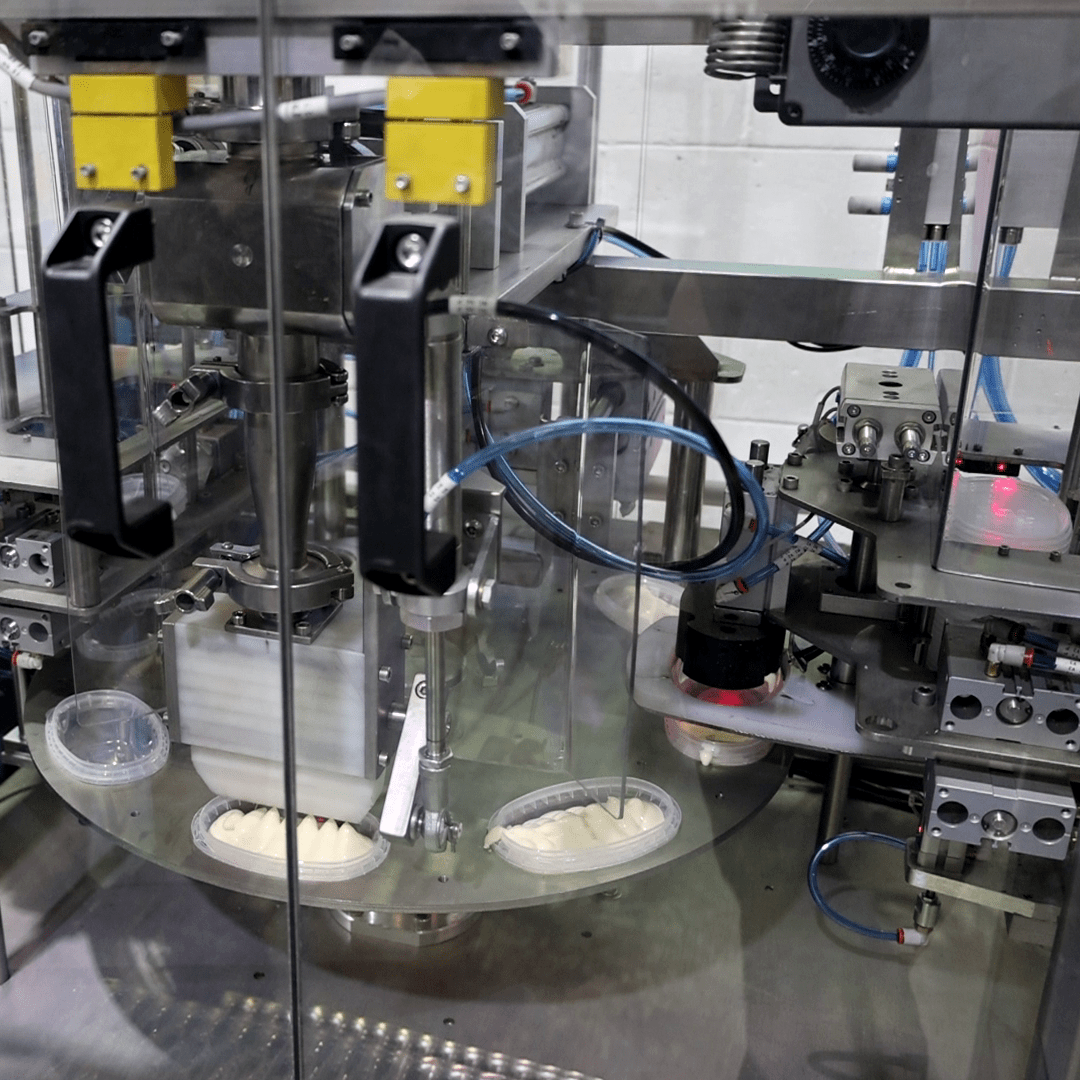

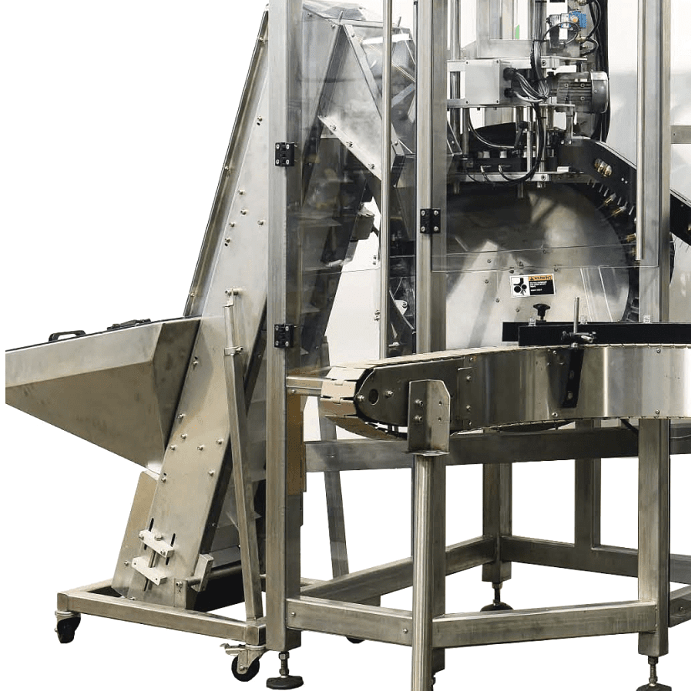

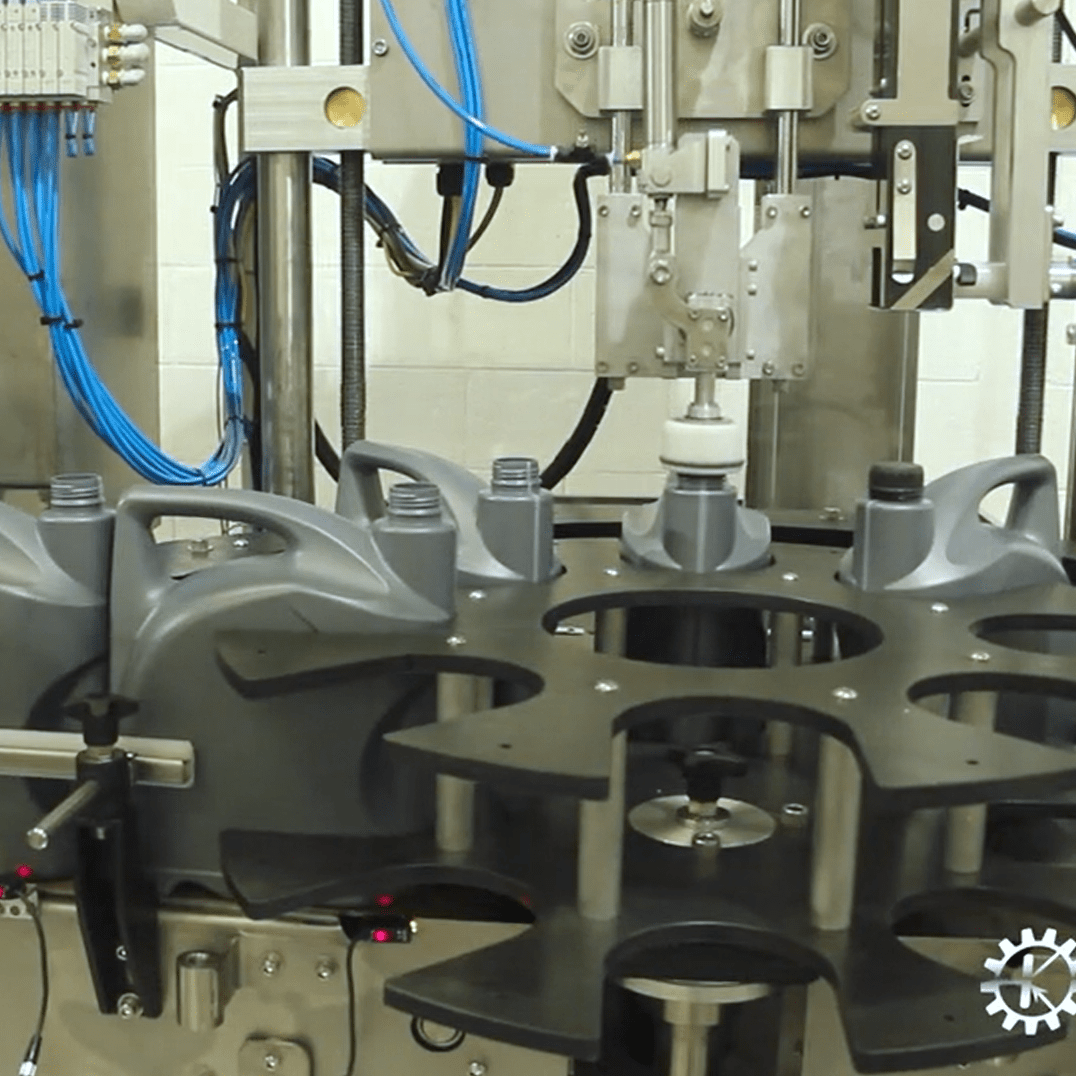

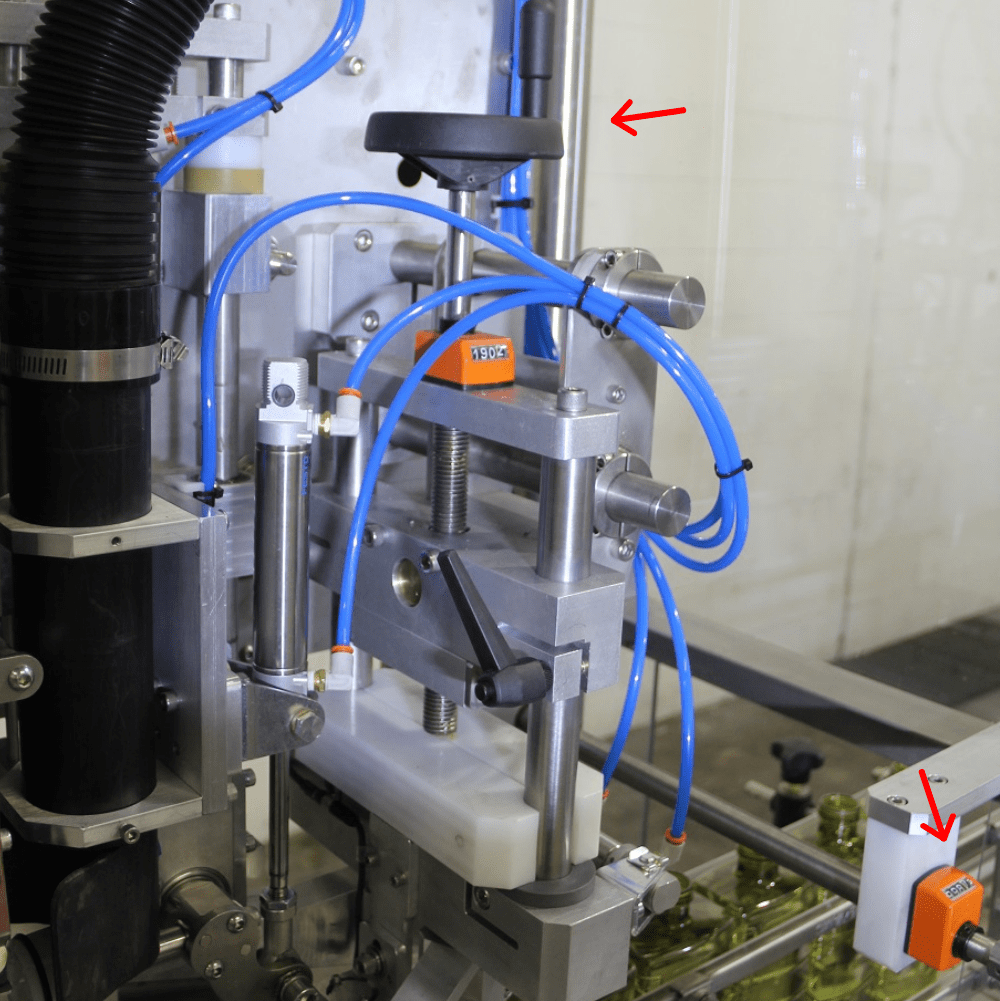

An automatic capping machine is designed to perform feeding, orienting and applying caps or lids to the bottles or containers. Filling and capping can be performed in a single automatic filling and capping machine.

Cap and lids types include: flat caps (screw-on, threaded or lug), flip-top lids, sprayers, pump-type, dropper, roll-on closures, press-top, twist-top caps, disc-top caps, pull/push caps, child resistant (CRC) closures, pilfer proof caps, etc.