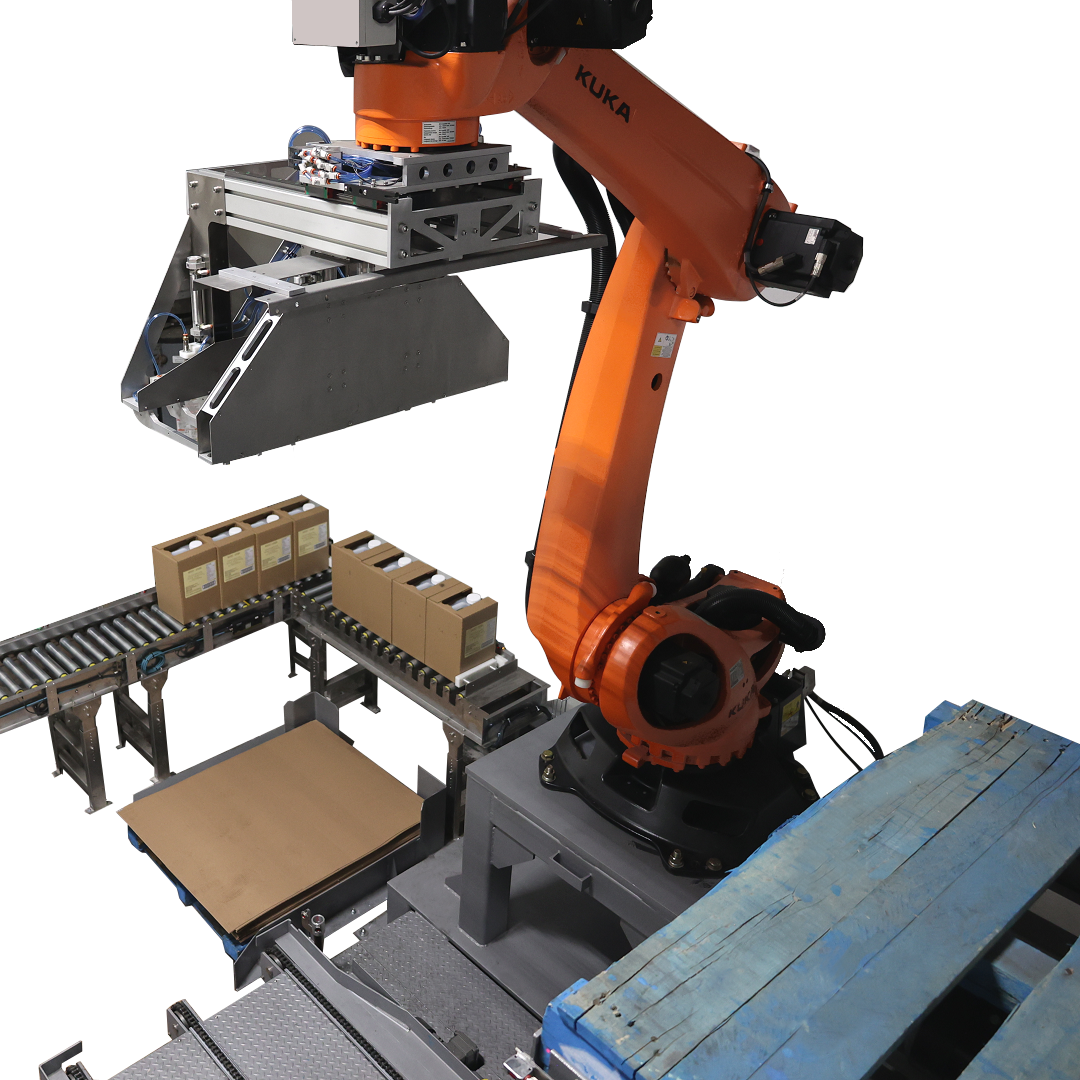

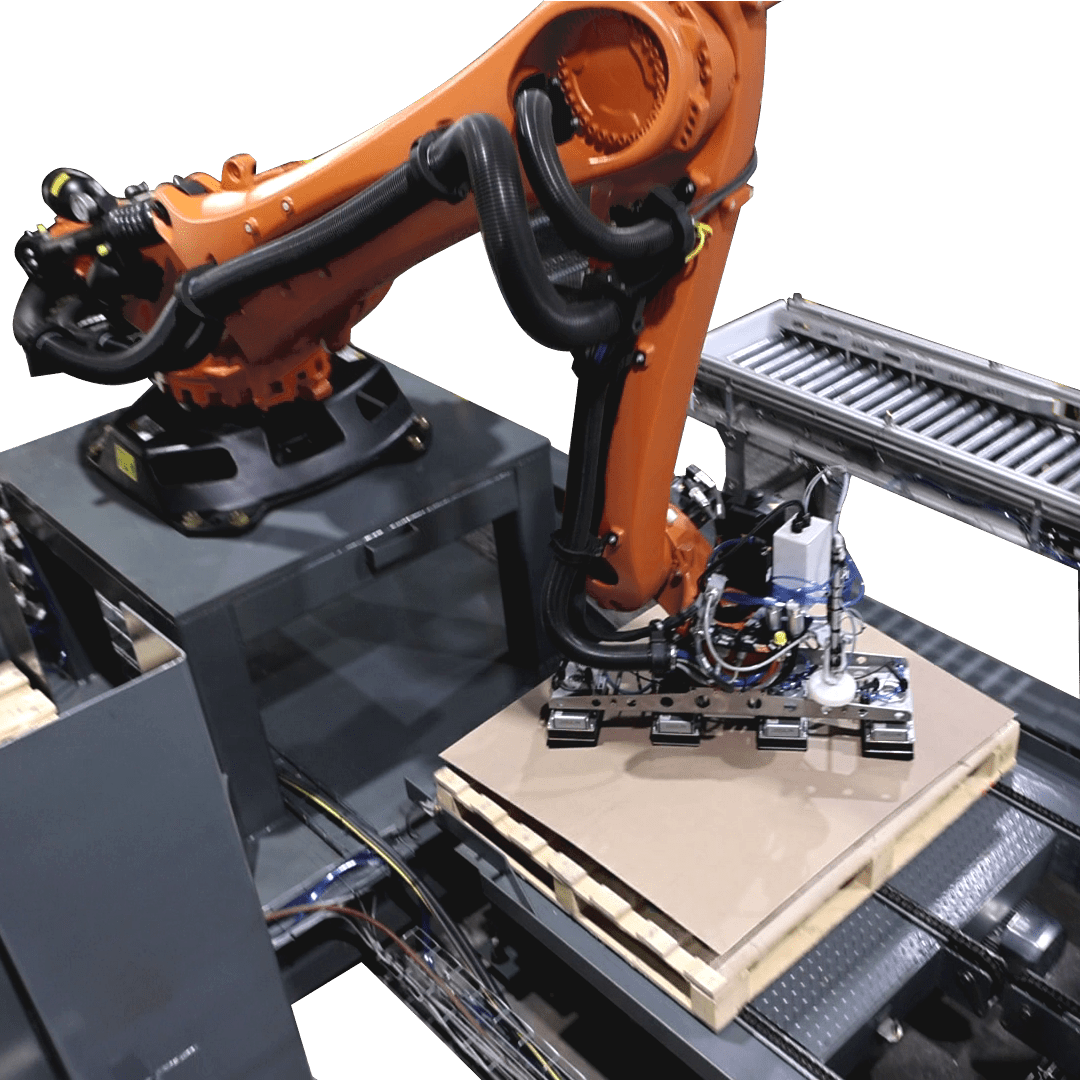

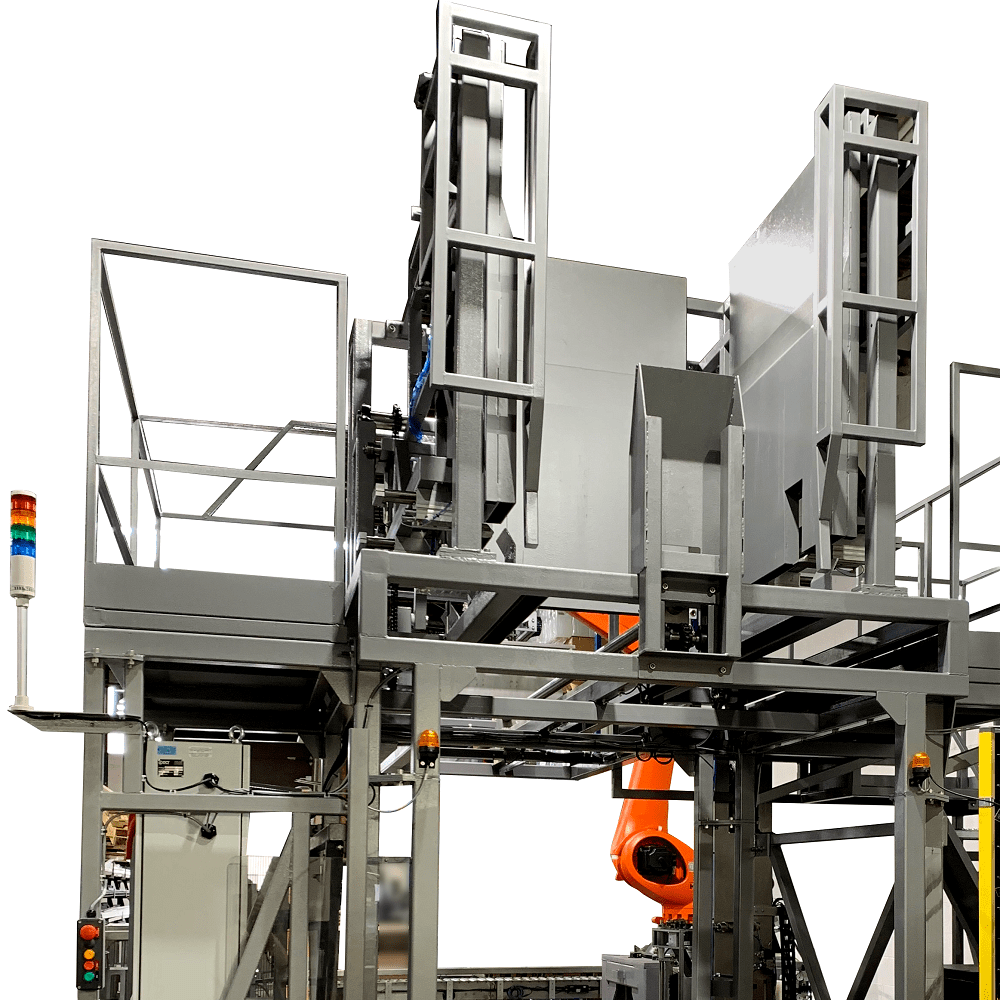

Automatic bottle palletizing machine

Packaging machines

The automatic bottle palletizing machine is built to perform automatic handling and stacking of bottles, containers, jug-in-box onto a standard wooden pallet, followed by pallet wrapping with stretch film.

Request A Quote