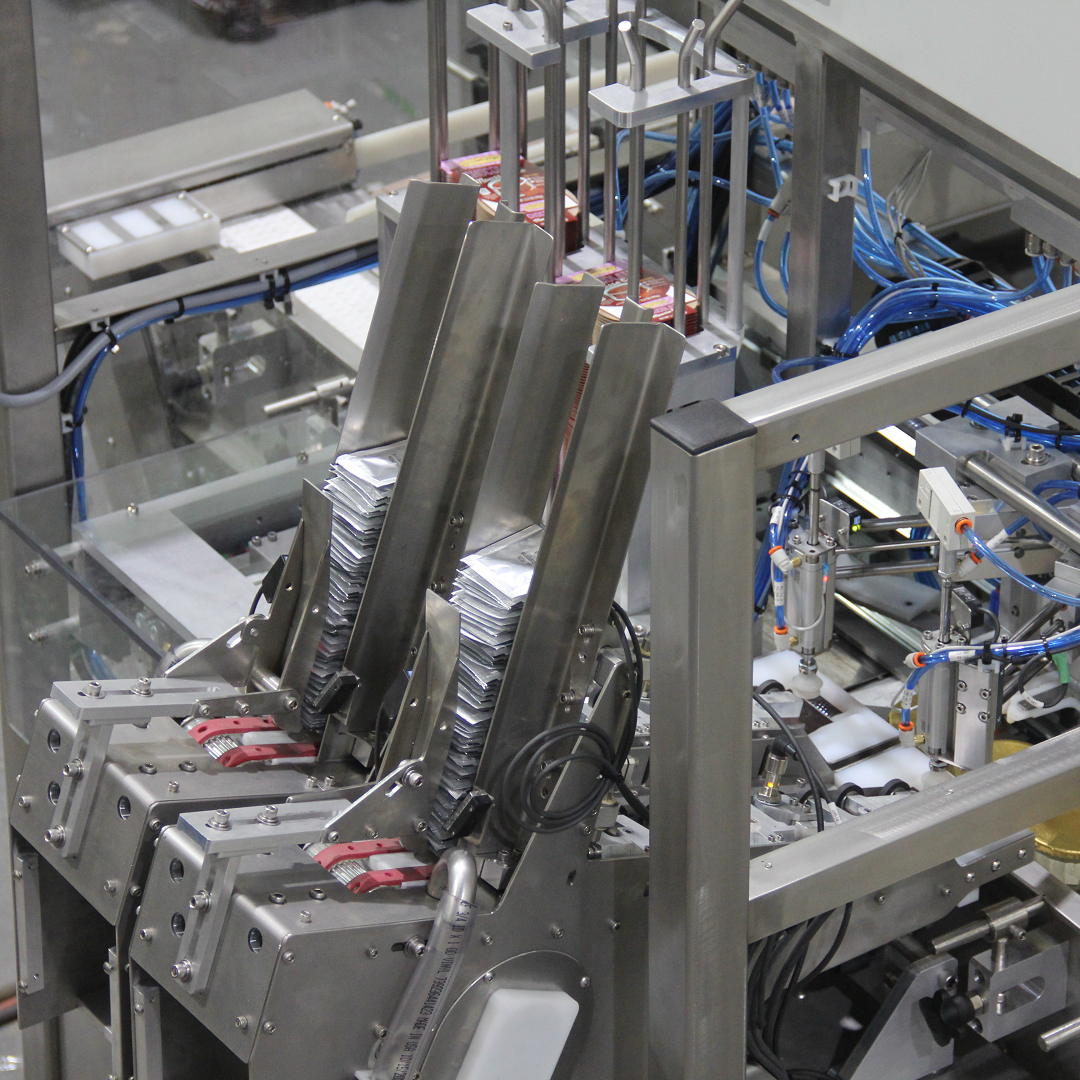

Automatic sleeve applicator

The automatic carton sleeve applicator machine is designed to put the sleeve on the product to protect the product from mechanical damages or enhance, improve or renew the product appeal. A carton sleeve itself is packaging that is slid over an existing container or packaging and is open on both sides so that the existing packaging remains visible on these sides. Such sleeves can be used to group several products together in the same packaging. The product can be fitted within a cardboard sleeve in either one of the two ways: the product packaging is slid into the sleeve or the sleeve is folded around the product packaging, and then closed and/or sealed. The products that can have a carton sleeve are fresh meals, butter, spreads, creams, and desserts.