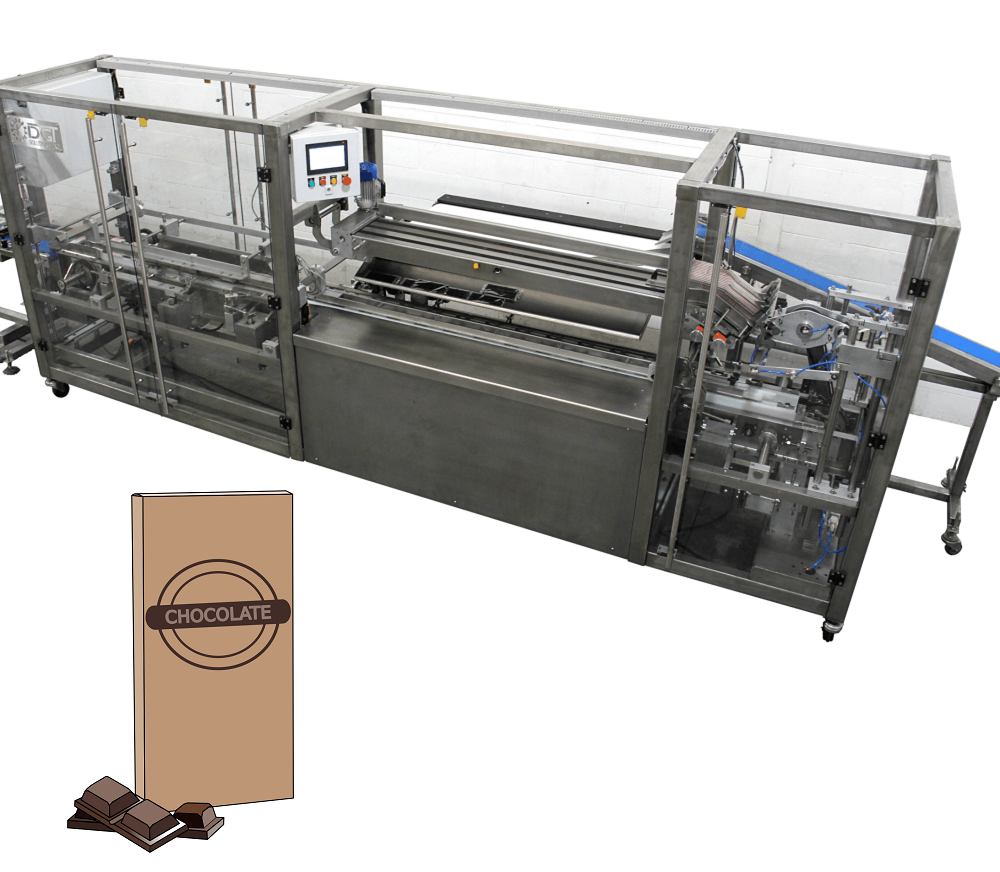

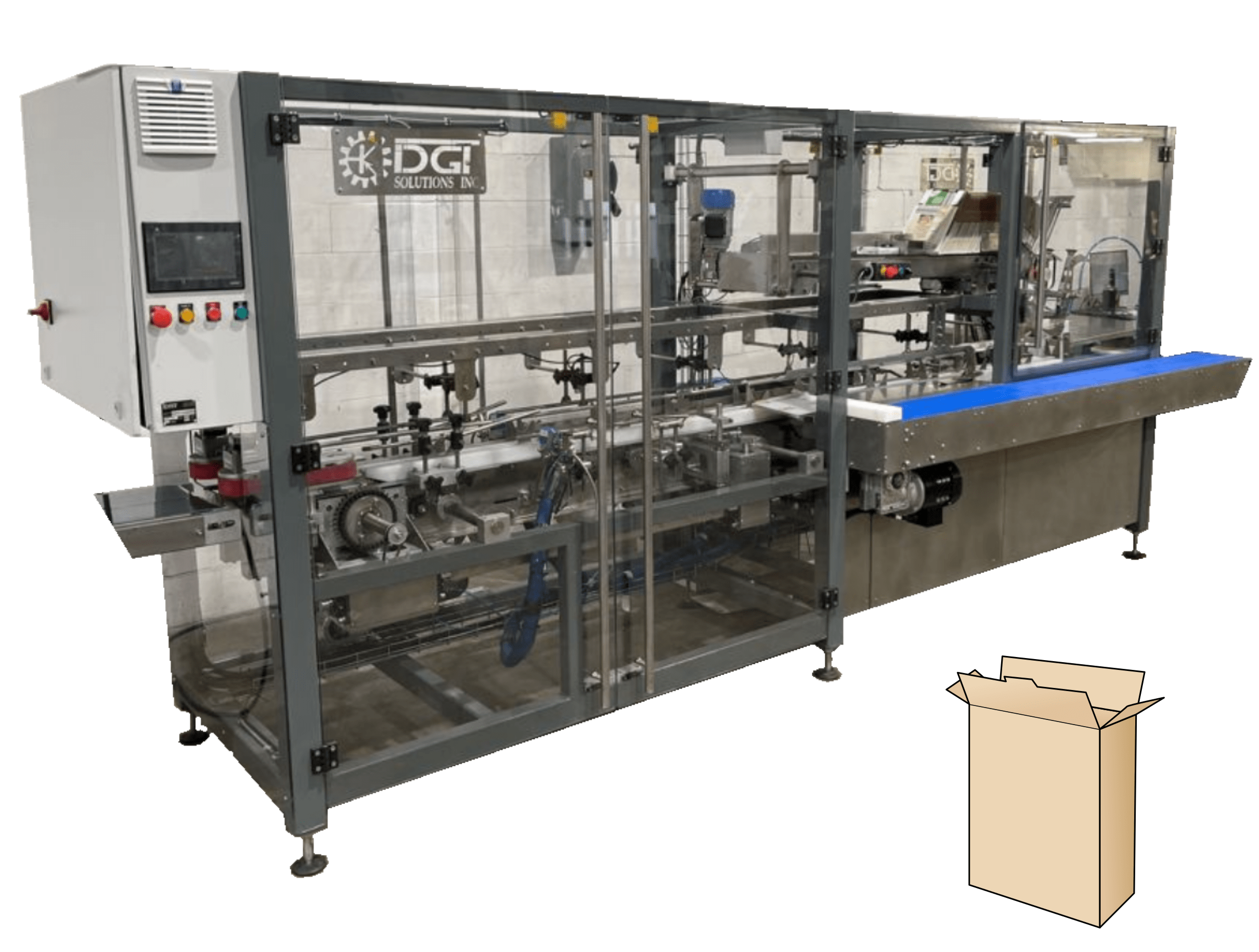

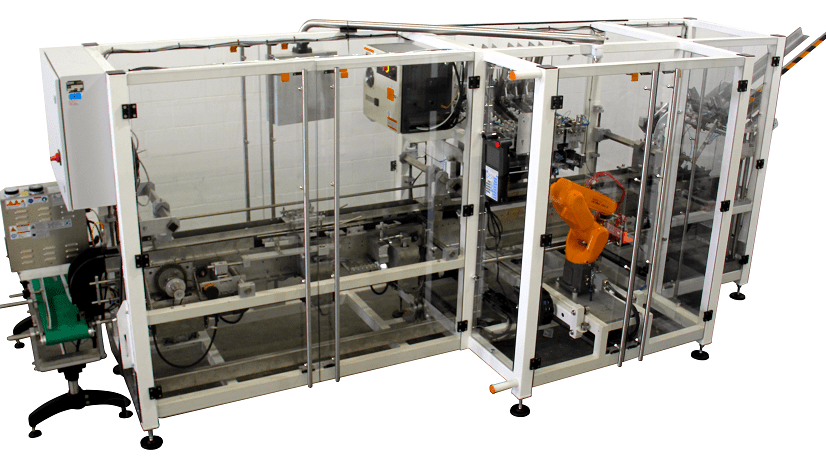

Flexible cartoning solutions

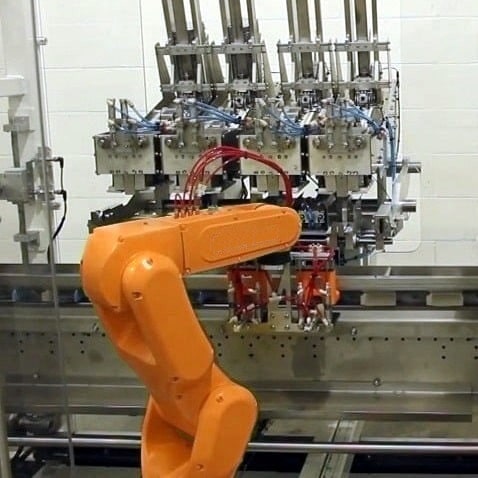

A cartoning machine or a cartoner is a packaging machine that picks up cartons from flat cardboard blanks, forms them and fills them with a rigid product, or a bag with the product or the number of products. The loading can be semi-automatic or fully automatic. After loading is completed, the complete cartons are closed and/or sealed.

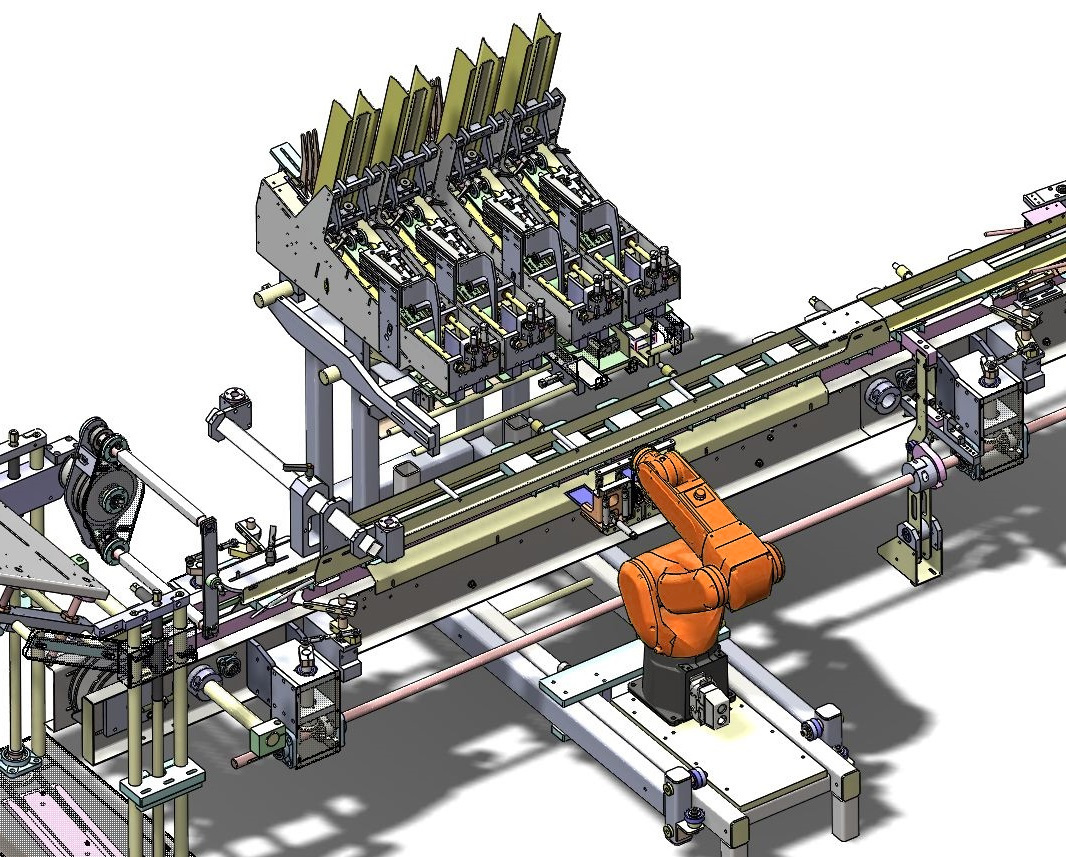

Our cartoning machines are ideal for packing flow-wraps, pouches, bags, thermoformed trays, and more. The machine can be optimized for tuck-in closing, sealed with hot melt glue, or stapled.

Request A Quote