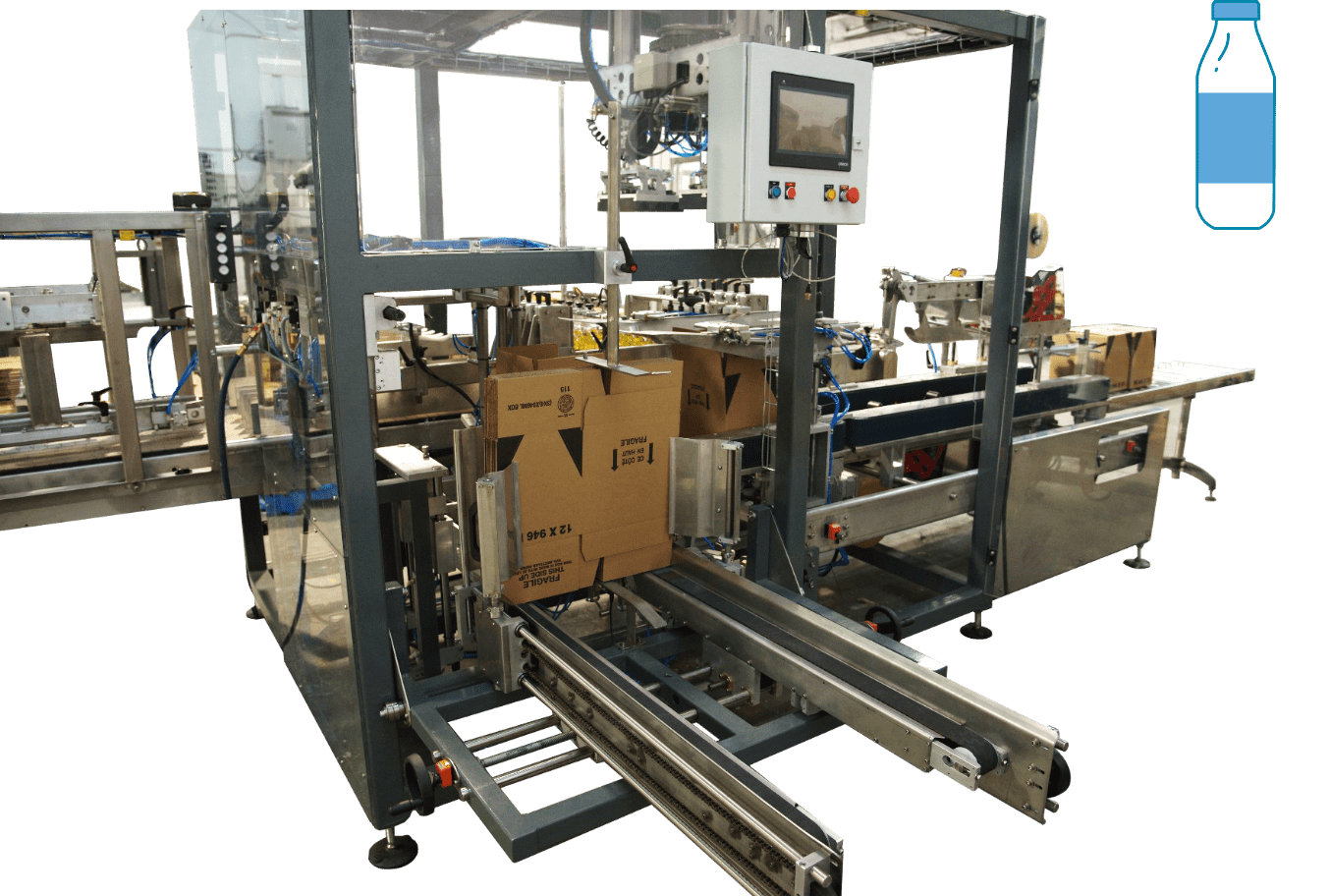

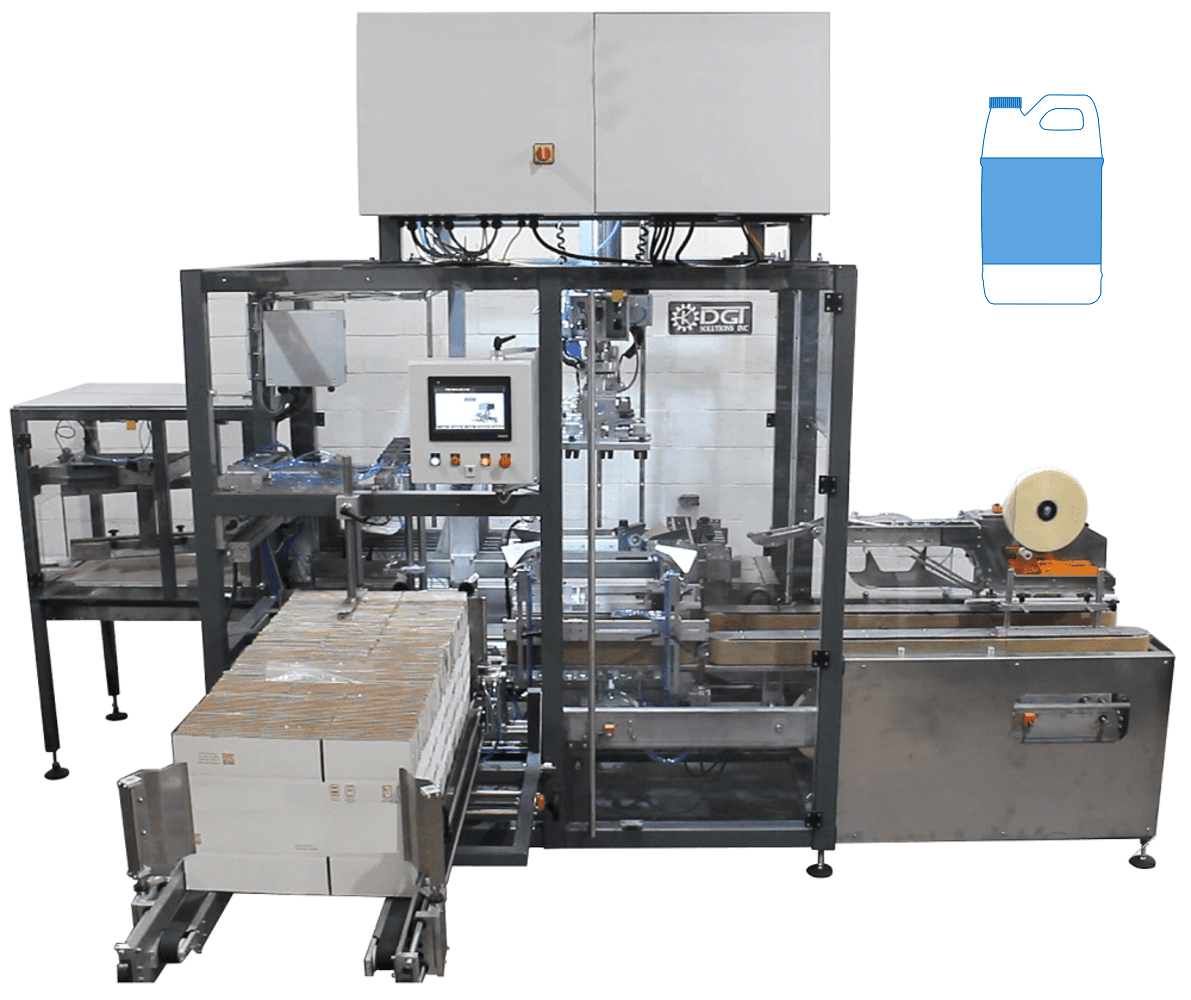

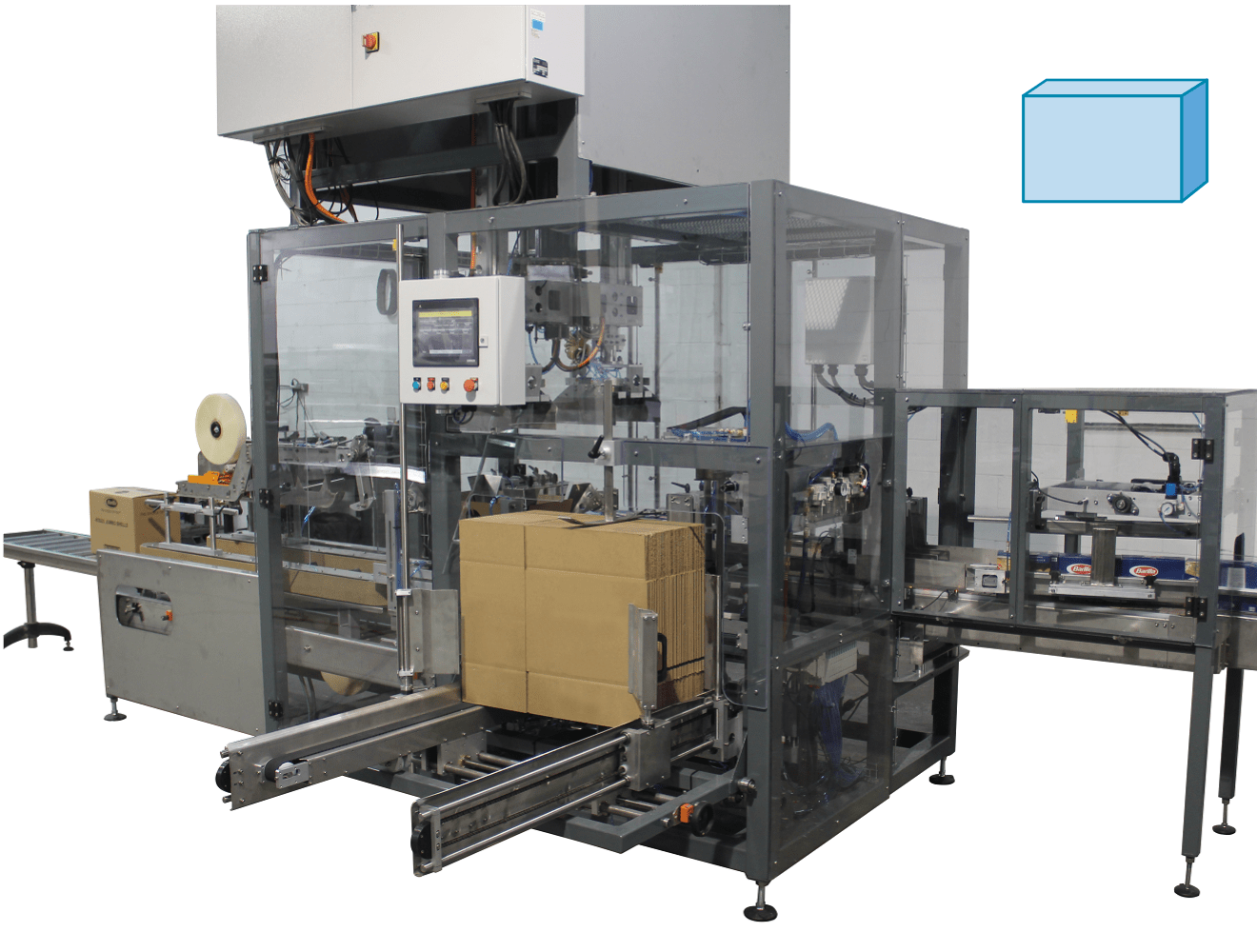

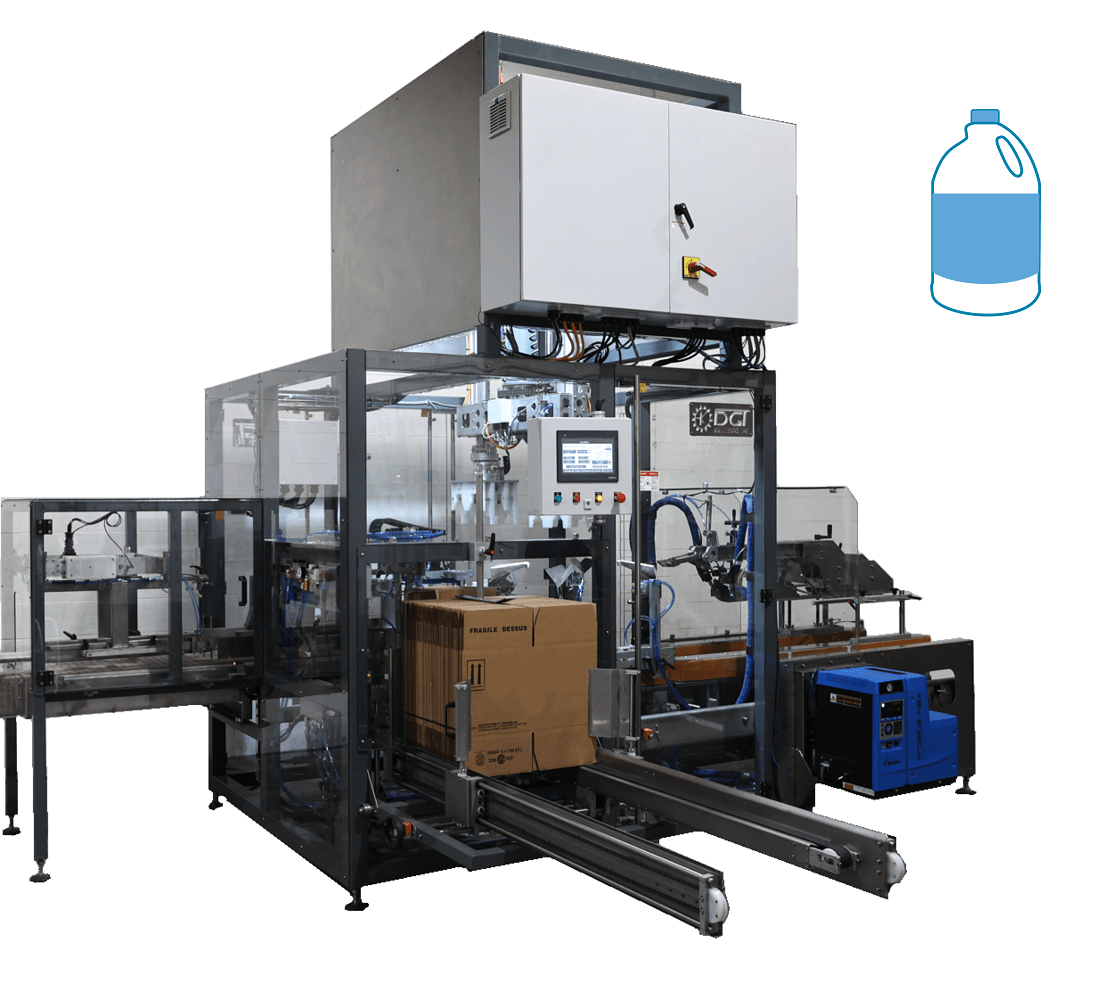

Packaging machines

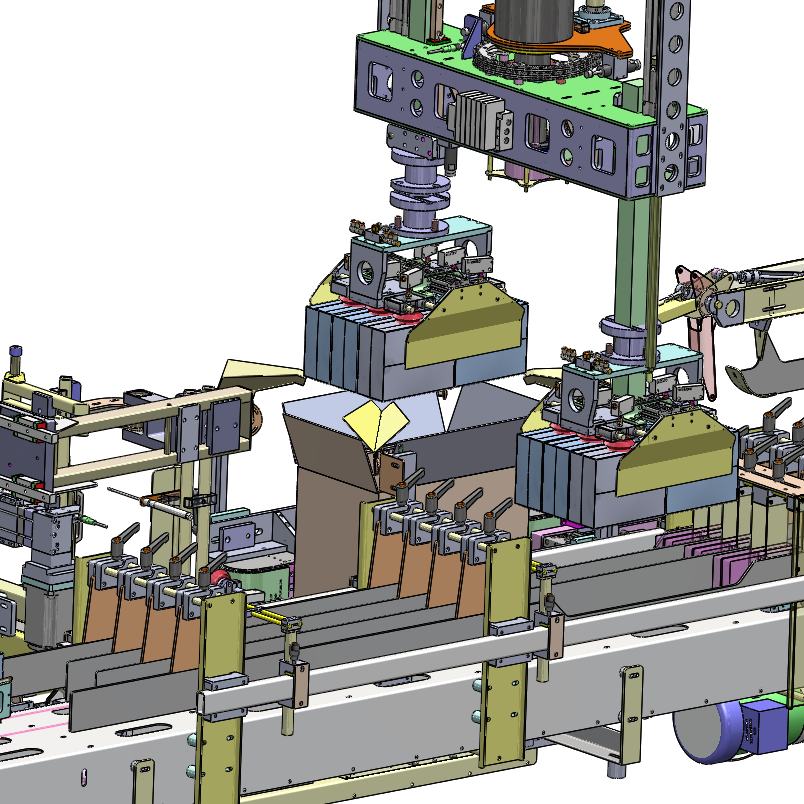

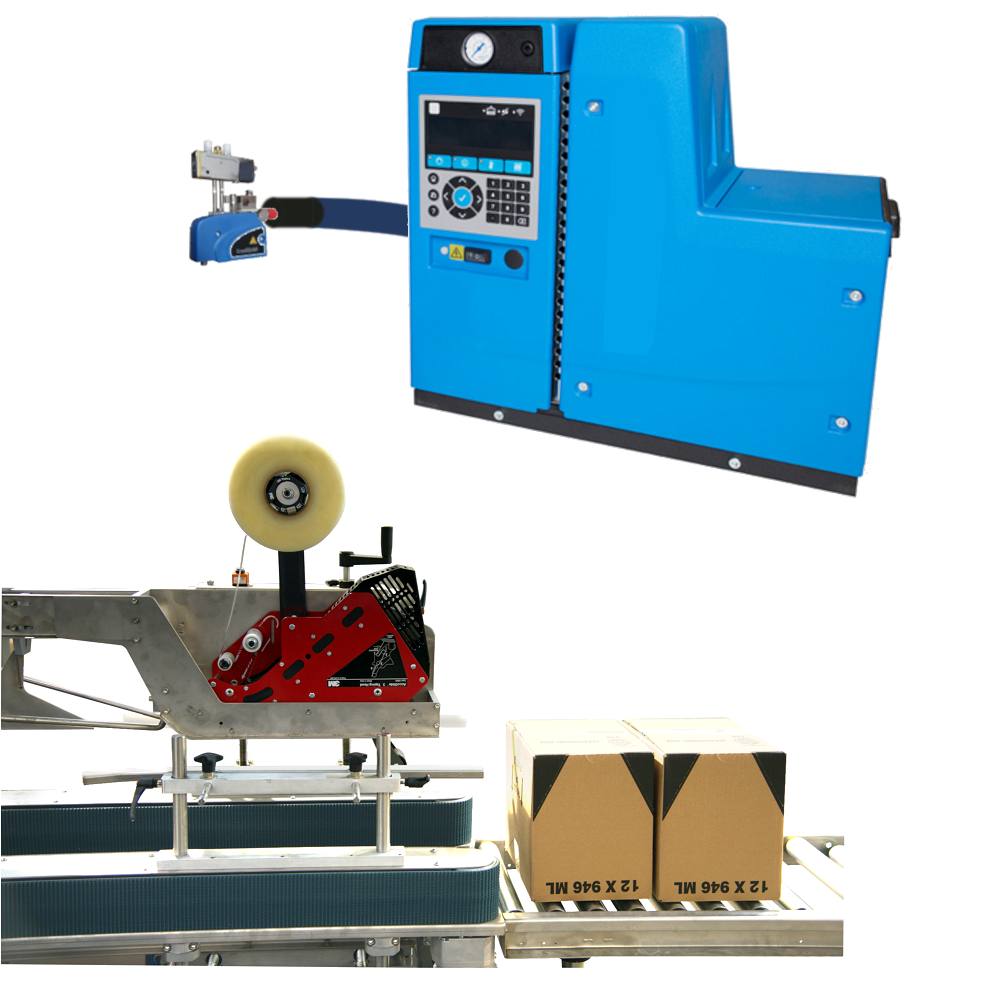

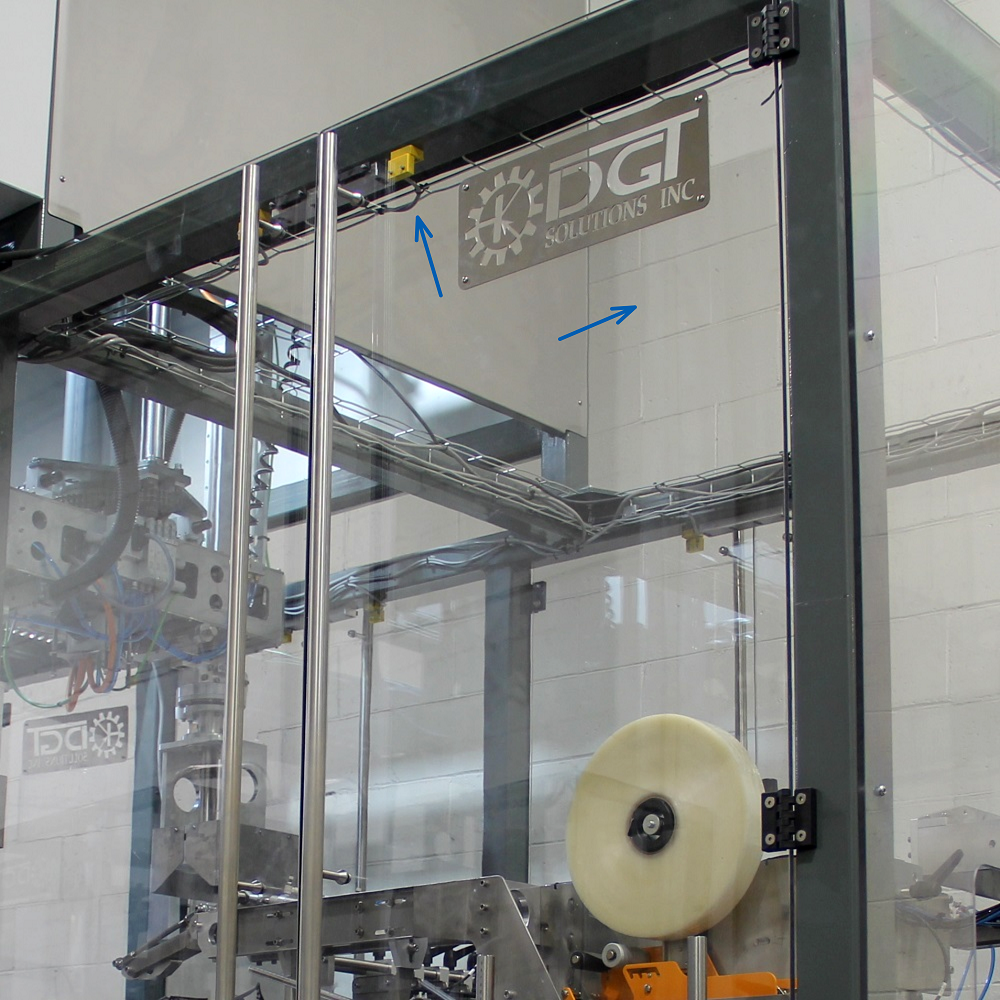

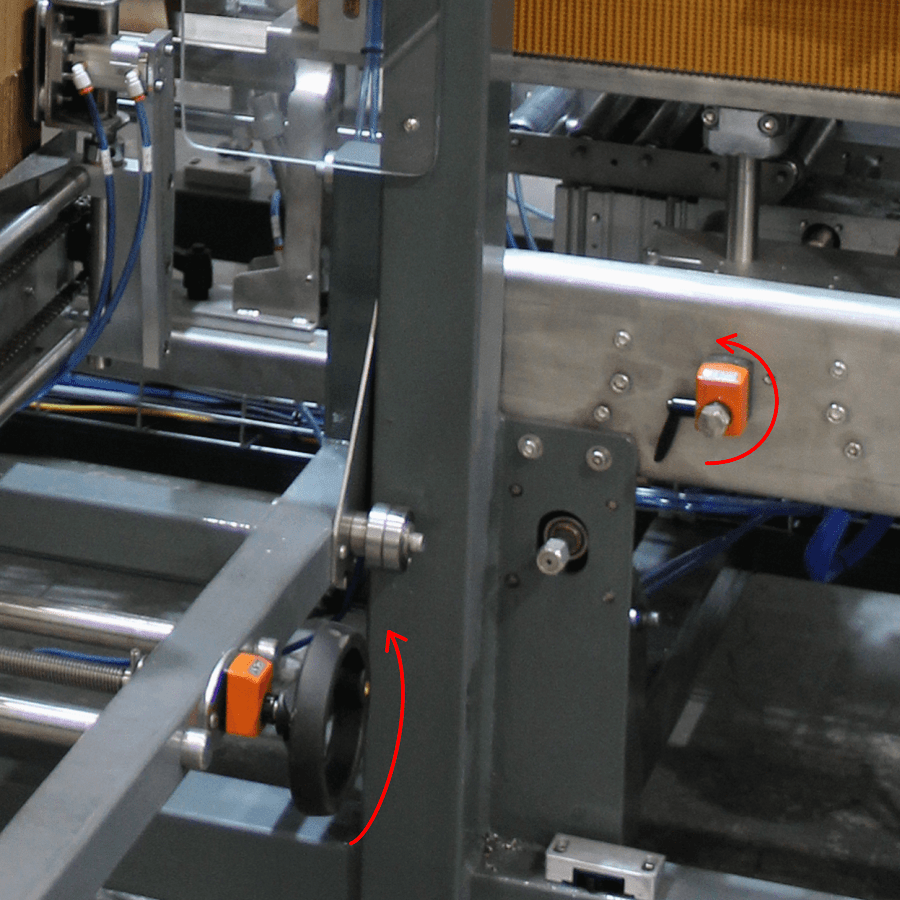

Our case packing machines are designed to pack a product in any shape or size. The case packer is made to individual specifications to perform feeding, product flow dividing, product picking and packing into cases or boxes. Custom-made grippers provide accurate product gripping and loading into the boxes. Following packing, the cases are closed and sealed either with adhesive tape or hot melt glue.

Request A Quote