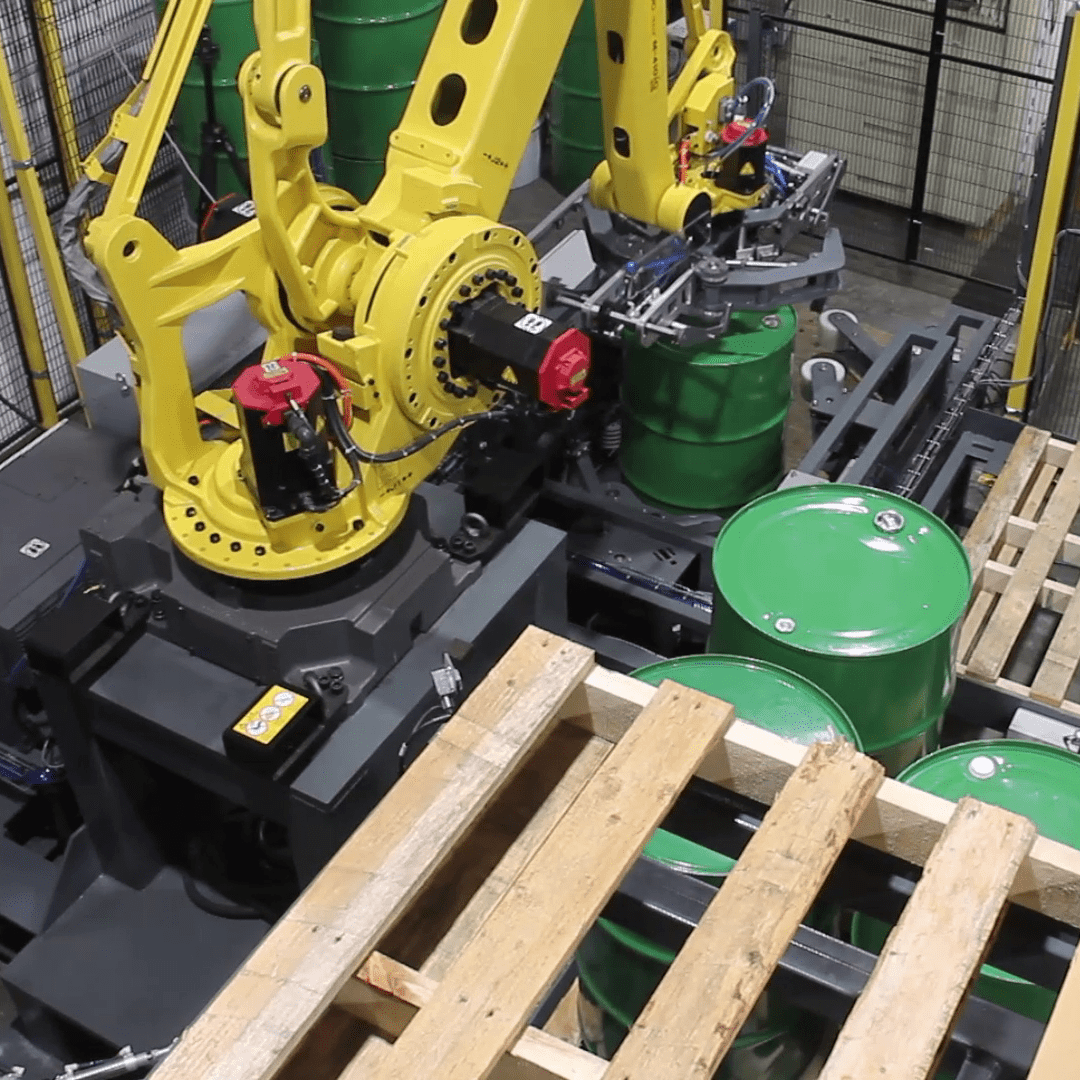

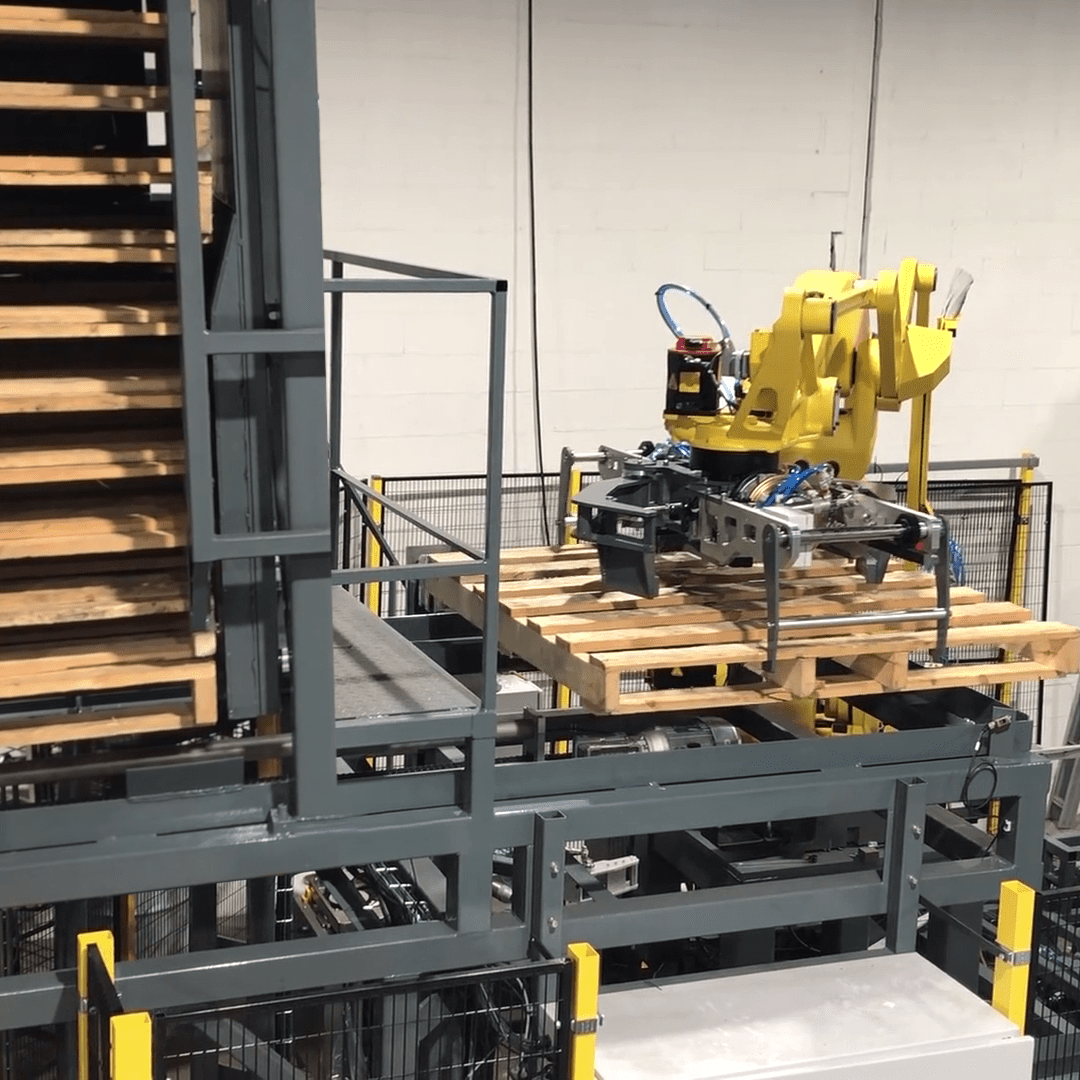

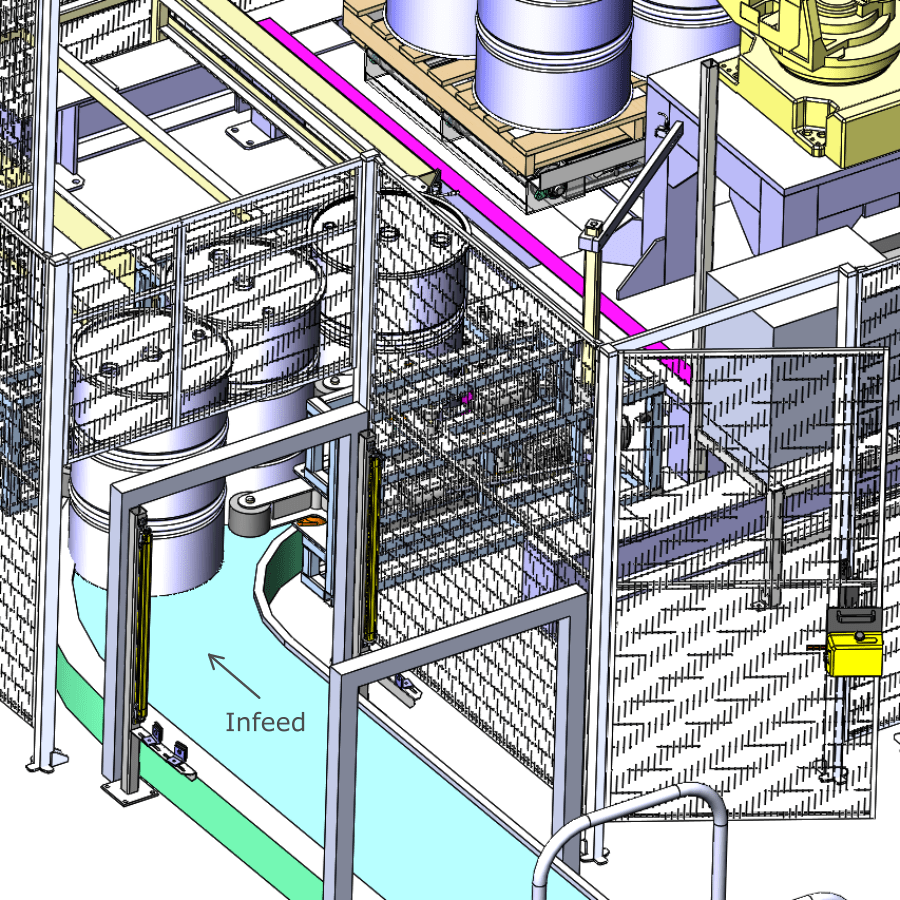

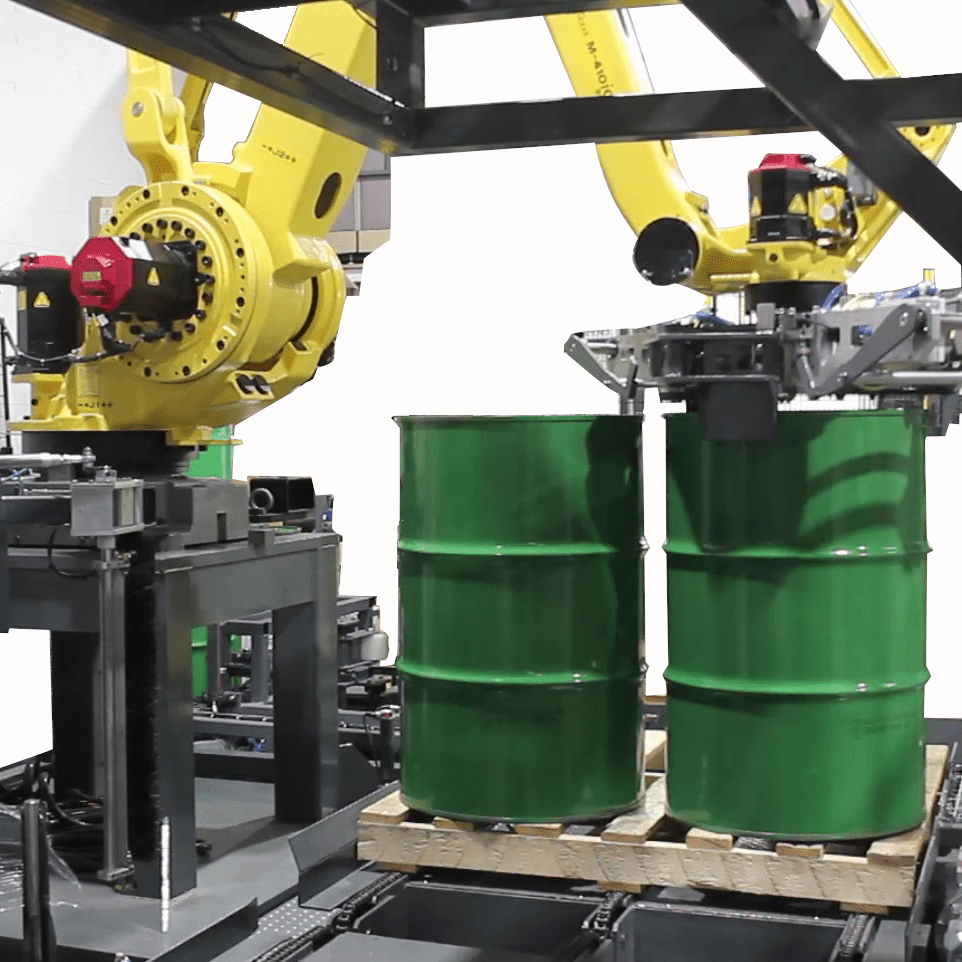

Automatic drum palletizer machine

Packaging machines

The automatic drum palletizer machine is built to perform automatic handling and stacking of large volume containers, for instance, drums, barrels or totes, onto a standard wooden pallet, usually followed by pallet wrapping with stretch film.

Request A Quote