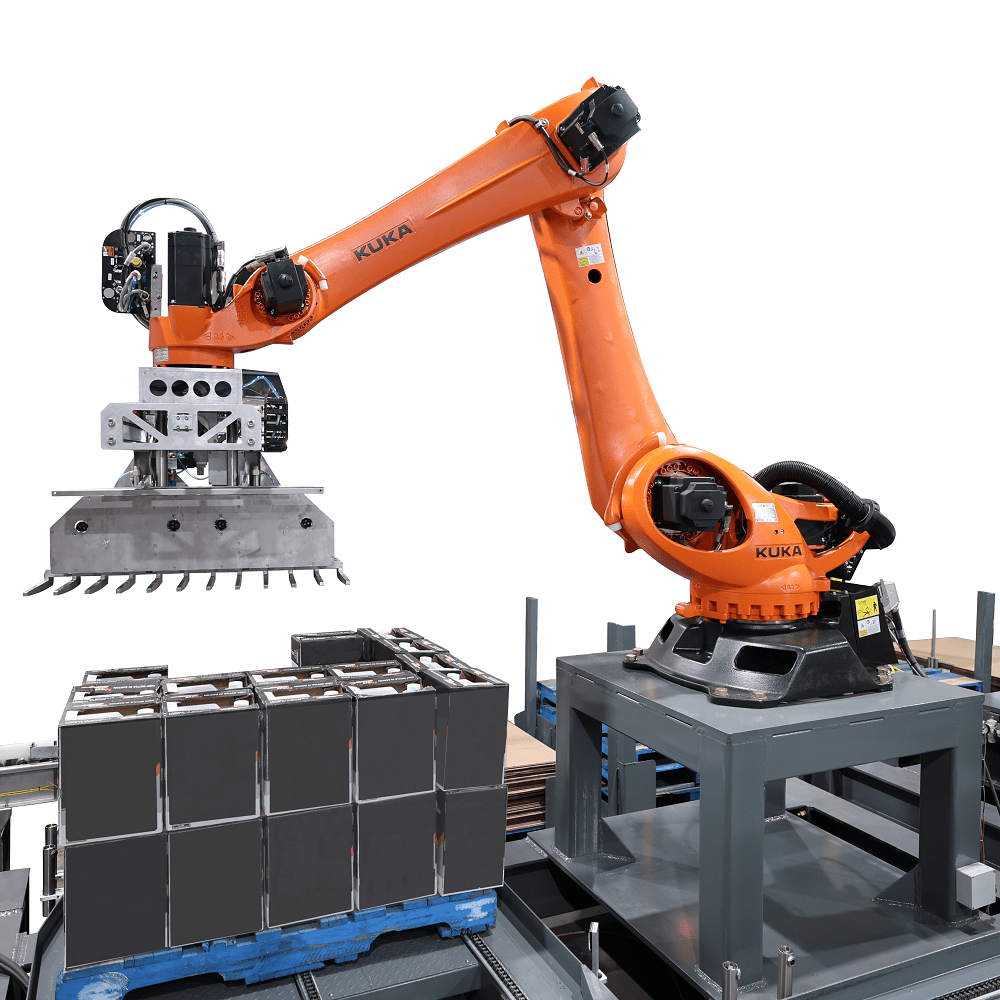

Dual robotic palletizing machine

Packaging machines

The automatic dual station robotic palletizing machine is designed to automate the palletizing of sealed boxes onto standard wooden pallets. This task is efficiently managed by two separate robots, with each robot dedicated to its respective line, handling different products, which are fed by two infeed conveyors. Each robot features a multi-functional end-of-arm tooling that picks pallets, handles slip-sheet, picks product and places it onto pallet according to the predetemined pattern. Following palletizing, each pallet undergoes wrapping with stretch film before being discharged by the output conveyor.

Request A Quote