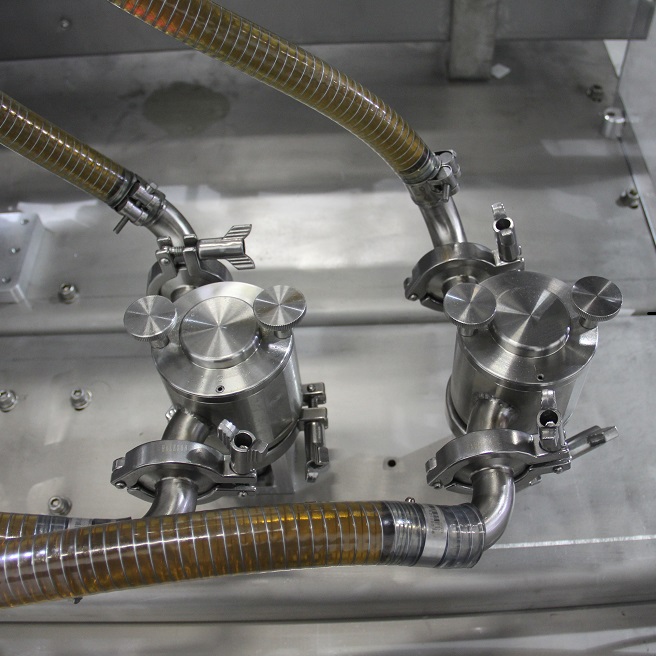

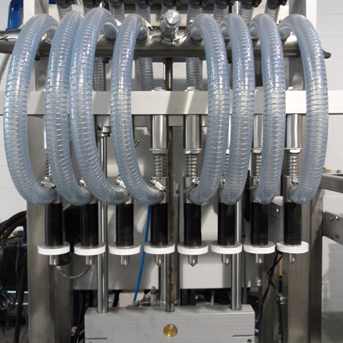

Parts and Hardware for Liquid Filling Machines

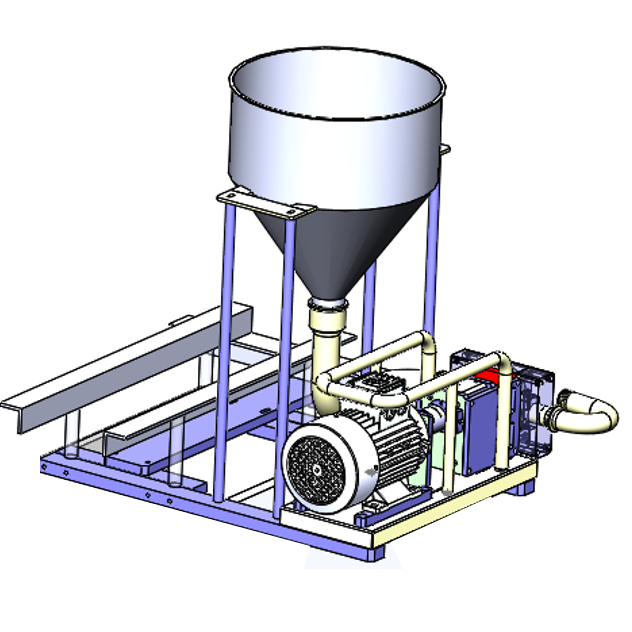

Automated processing equipment

We have a wide range of filling solutions, including both semi-automatic and automatic equipment. To ensure their normal and efficient operation, DGT Solutions Inc. offers a variety of spare, and replacement parts for your filling system.

Request A Quote