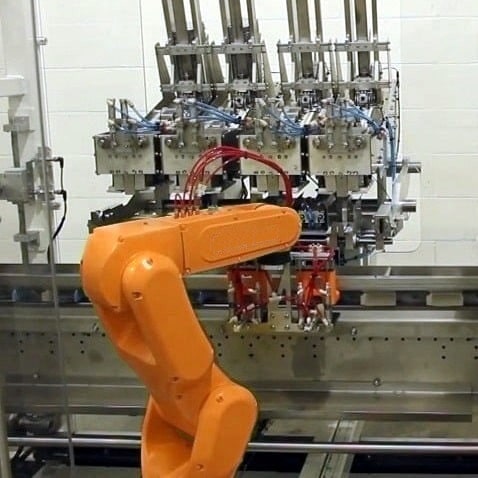

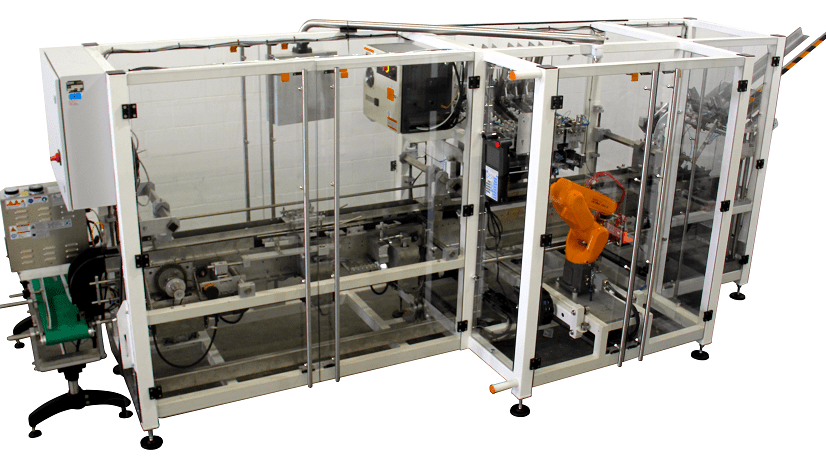

Automatic cartoner machine with robotic loader for multiple identical products

Packaging machines

This machine is designed to perform carton preforming, counting and picking of multiple identical products (such as pouches, sachets, single-use products) by a robot, inserting them into preformed cartons, followed by carton closing.