Working closely with our customers and focusing on their production needs, we, DGT Solutions Inc., expertly design and build innovative, customized solutions for a wide variety of industries.

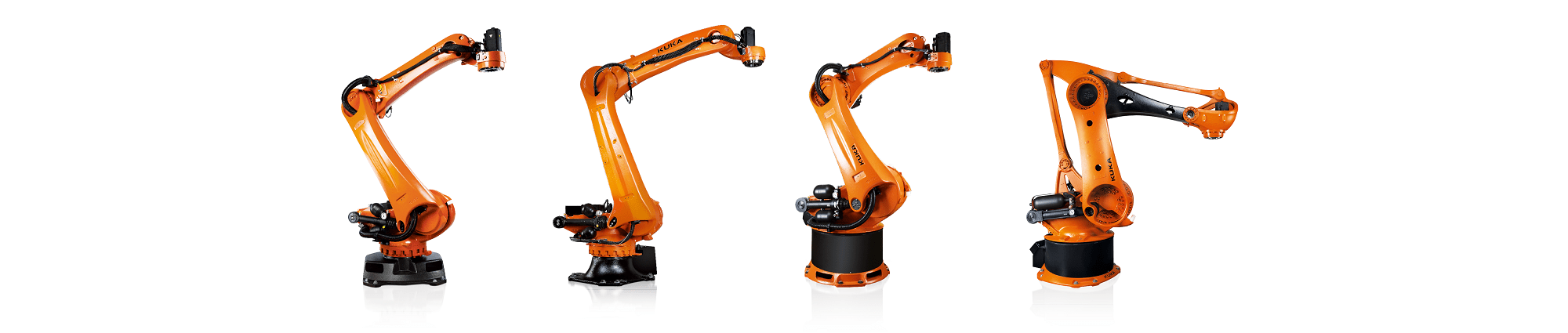

Different types of automation systems provide our clients with benefits such as decreased production cycle times, higher production rates, better product quality, and improved safety for the workers. We excel at making industrial production processes more flexible and simpler while ensuring a higher efficiency.

DGT Solutions Inc. has the wide range of machines and the flexibility to provide automation to countless industries. Here are just a few examples.

Automation and robotics have an important role to play in the food production industry by providing technology that will ensure the sector continues to meet the rising demand for high-quality yet affordable food products.

In food industry particularly, more businesses have been employing automation systems and robots to improve overall efficiency. To comply with food safety regulations, all our machines are manufactured with appropriate materials that as wellallow easy and quick clean-up.

Each week, the pharmaceutical industry produces millions of pharmaceutical products in the form of blister packs, bottles, cartons, and boxes. All these products must be carefully packaged and shipped to distributors. Most pharmaceutical packaging systems use automated processes to manage product filling into a container, its capping , labeling, and packing into the boxes/cases. We understand that hygienic designs are crucial, and we only use pharmaceutical-grade sterile materials such as sanitary stainless steel and food-grade plastics. Optionally, the machines can be made wash-down compatible.

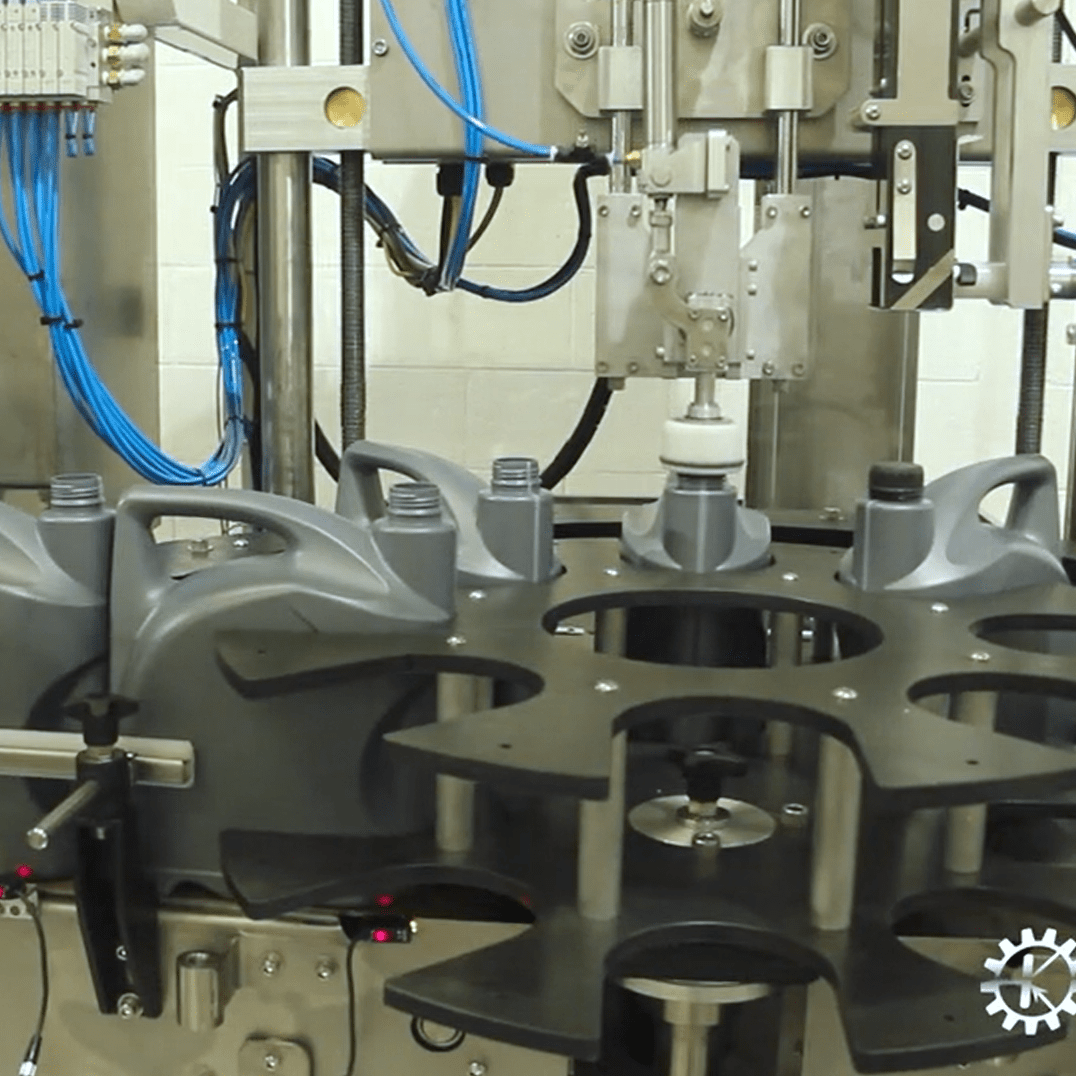

The demand for edible oils and fats is growing steadily. The reason for this increased demand lies both in the popularity of convenience food and in rising population numbers. A growing concern for the environment and high fuel prices also promote the use of biofuels produced from vegetable oil. So, for this reason, edible oils producers are looking for new solutions to increase the efficiency of production. DGT Solutions Inc. is here to provide them with these solutions. Our systems can help automate different edible oils production processes including, but not limited to bottle cleaning, filling and capping, as well as labeling and applying sleeves to protect the container cap from opening.

With the growth of car production, the need for lubrication products is expected to grow. Lubricant oil filling machines provided by DGT Solutions Inc. can help you reach desired high productivity levels to meet the growing demand of the market. These machines are designed based on the client's samples and are adjustable to work with many different container sizes and styles. The production processes that can be automated are, among others, filling, labeling, case packing, and palletizing.

As chemicals can be corrosive or flammable in nature, chemical manufacturers must meet strict health and safety requirements. Machines should be easy to clean and designed to avoid spills to prevent corrosion and cross-contamination between different products. Machines should be very easy to use, with minimal training required for safe operation, and incorporate user-friendly intuitive interfaces that can cope with harsh environments.

The automation systems manufactured by DGT Solutions Inc. for filling and packaging cosmetics are designed to suit the rapid product changes in the cosmetics industry. This industry is probably one of the most demanding in terms of the variety in shapes and sizes of the containers. Each one of the automation systems we design is created with the specific container dimensions in mind. In addition, our systems can be made adjustable for a few different container sizes to provide flexibility in production. Streamlining processes such as container filling with the product, sealing, and labeling will allow you to reach all your production goals.

New, automated beverage packaging solutions can help manufacturers stay competitive and navigate rapidly changing markets. Robotic applications such as palletizers are the modern components of automated end-of-line packaging operations for beverage manufacturers. They allow a high palletization rate while eliminating picking and handling errors.