Labeling Machines | Labelers

The labeling equipment performs the application of labels onto containers, cans, glass bottles, plastic bottles, buckets, pails, and other types of containers of all shapes and sizes. Bags labeling is also available. These labeling machines may be simply integrated into an existing production line or be operated as a stand-alone solution.

Our labeling machines come with a variety of features, including:

Different products and shapes labeling

Labeling glass and plastic bottles, containers, cans, cardboard boxes, cases, and plastic bags.

Double Side Labeling

A simultaneous application label on both sides of the product is available on request.

Conveying and Supporting Belts

The material of the belts used on a labeling machine depends on the material of the container or packaging to be labeled and the production speed required.

Safety Seal Application

In the case of cartons, the safety seal labeler is usually needed to apply a safety seal on the carton’s edge. Safety seals provide secure tamper protection and can display additional product information.

Sanitary Frame

For the food industry, cosmetic and pharmaceutical applications, the right material choice for the frame and machine parts is stainless steel and food-grade plastic which fully meet the requirements of the above-mentioned industries.

Customized Solutions

Our labeling machines offer flexibility for different product shapes and sizes. Whether it's a cylindrical bottle, flat box, or irregularly shaped container, our labeling solutions can be customized to meet your specific requirements.

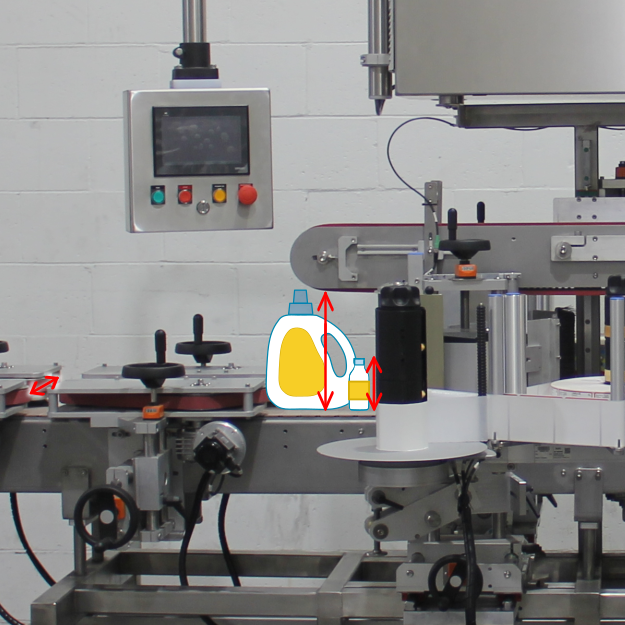

Efficient Product Changeover

The labeling machine units can be adjusted according to the container size. The adjustments can be manual and/or pre-programmed and chosen from the options on the HMI menu.

Trays and Flat Packaging Top and Bottom Labeling

Simultaneous top and bottom labeling combines two synchronized labeling heads. In this case, the labeling machine applies labels on both sides of a flat product such as plastic packaging, packaging trays, pouch, or carton.

Pail Labeling

In the case of large cylindrical or conical containers (for instance, pails), the vacuum belt labeling system helps apply the label accurately on the larger surface of the container.