Robot Grippers for Palletizer Machines

Robot grippers play a crucial role in the efficiency and versatility of palletizer machines, offering various options to cater to different materials, shapes, and sizes.

Here's an overview of different robot grippers commonly used in palletizing applications:

-

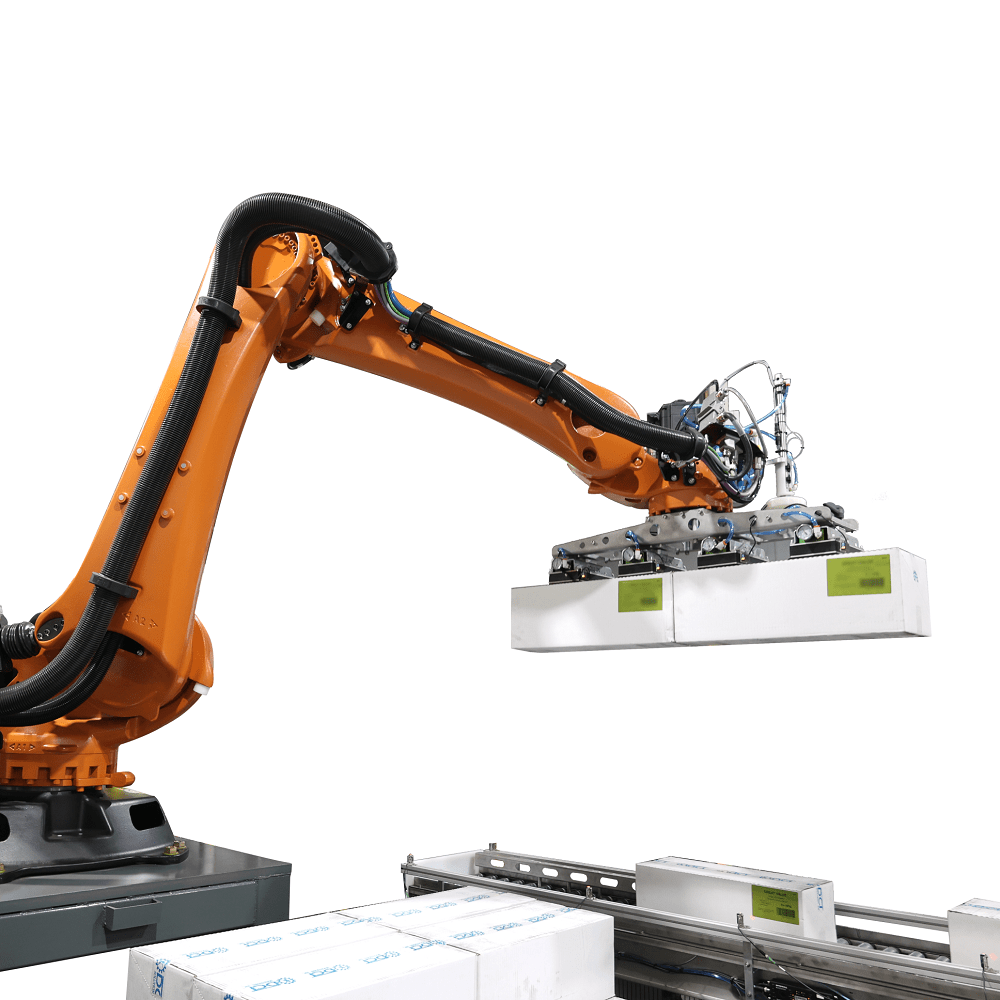

Vacuum Grippers:

- Utilize suction cups driven by compressed air to grip and lift objects.

- Pick up flat, smooth-surfaced items like boxes, cartons, containers, packages, and cases.

- Gently handle a variety of materials, and effective for high-speed operations.

-

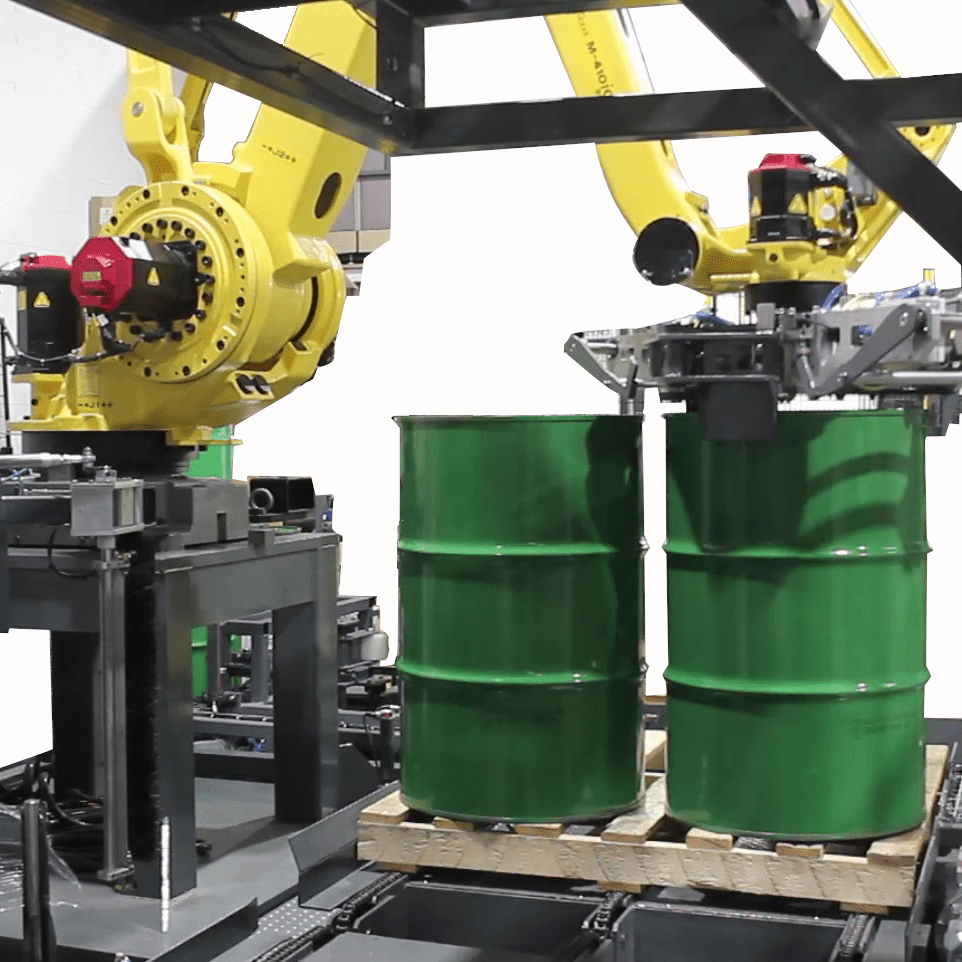

Mechanical Grippers:

- Employ mechanical jaws or fingers to grasp and lift objects.

- Handle objects with defined shapes and sizes, such as bottles or containers.

- Provide robust and precise gripping, suitable for heavier loads, and adaptable to various shapes.

-

Fork Grippers:

- Feature prongs to slide under a product and lift it.

- Handle bags, pouches, or products with irregular shapes.

- Effective for items with no easily grippable surfaces, versatile for different product types.

-

Custom-Designed Grippers:

- Designed to specific shapes or requirements of products.

- Ideal for irregularly shaped objects or products with unique handling needs.

- Precision-engineered for specific applications, ensuring a secure grip on specialized items.

-

Vacuum and Mechanical Hybrid Grippers:

- Combine vacuum and mechanical elements for a broader range of products, providing adaptability and enhanced versatility.

- The combination of vacuum and mechanical elements allows for improved gripping across various shapes and sizes.

-

Magnetic Grippers:

- Use magnets to grasp and lift ferrous materials.

- Handling metal products or containers.

- Efficient for materials that are magnetically receptive, providing a secure grip.

-

Soft Grippers:

- Made of compliant materials to gently envelop and lift items.

- Ideal for Fragile or delicate items.

- Minimize the risk of product damage, suitable for items that may deform under pressure.

In palletizing applications, choosing the right gripper depends on the nature of the products being handled. The versatility of these grippers allows palletizer machines to adapt to a wide range of industries, from food and beverage to manufacturing and logistics.

Robotic Palletizer Manufacturer Canada | Automated Palletising Robot

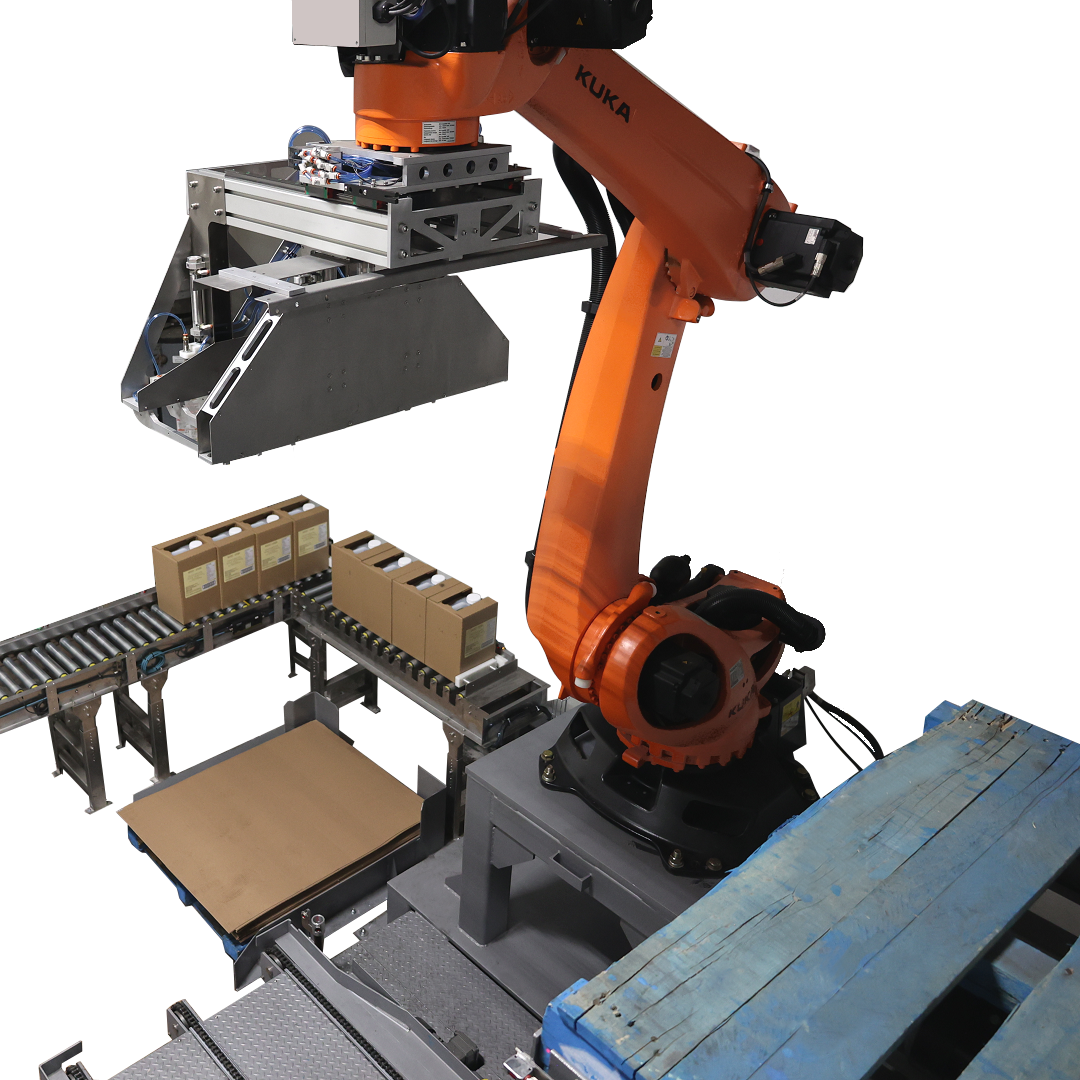

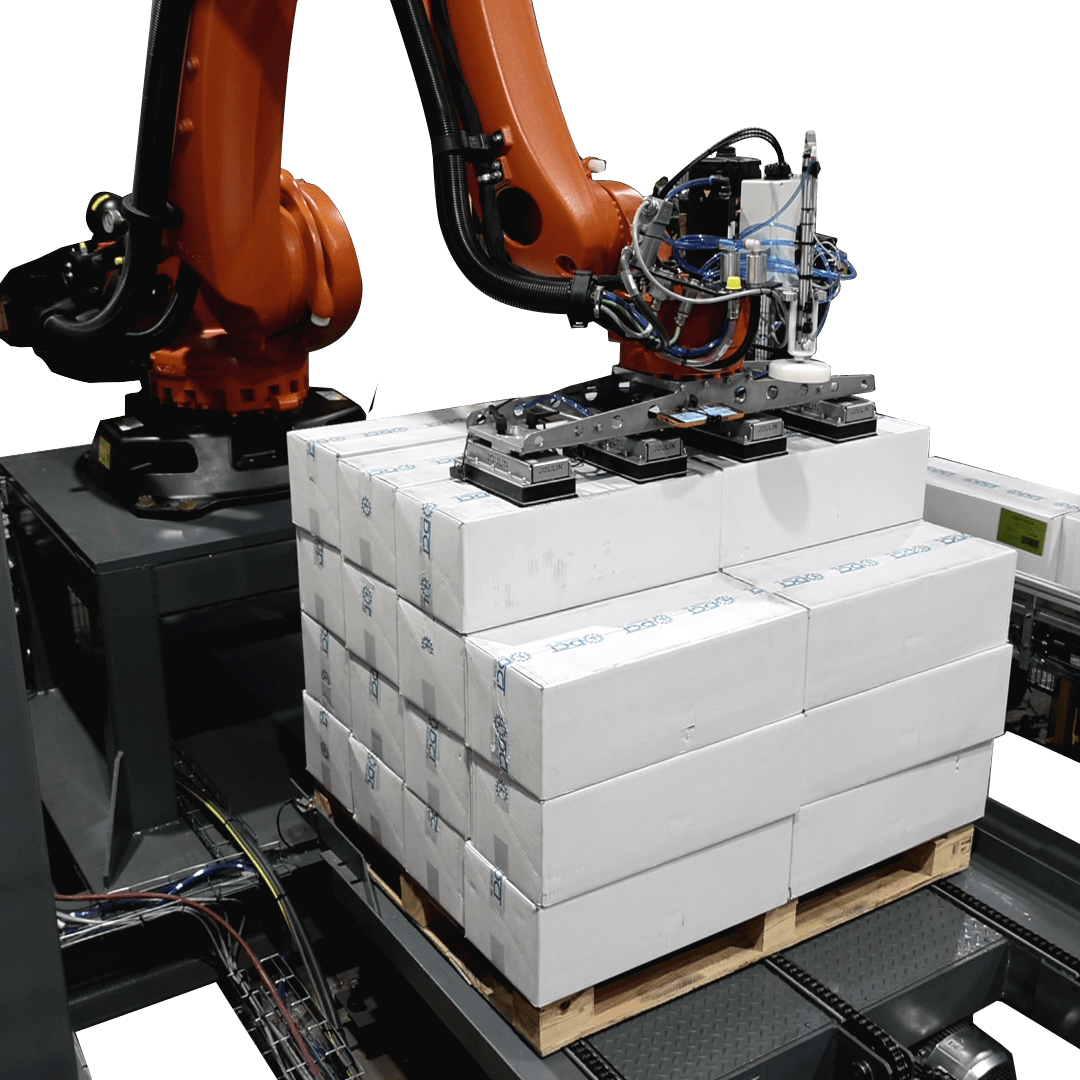

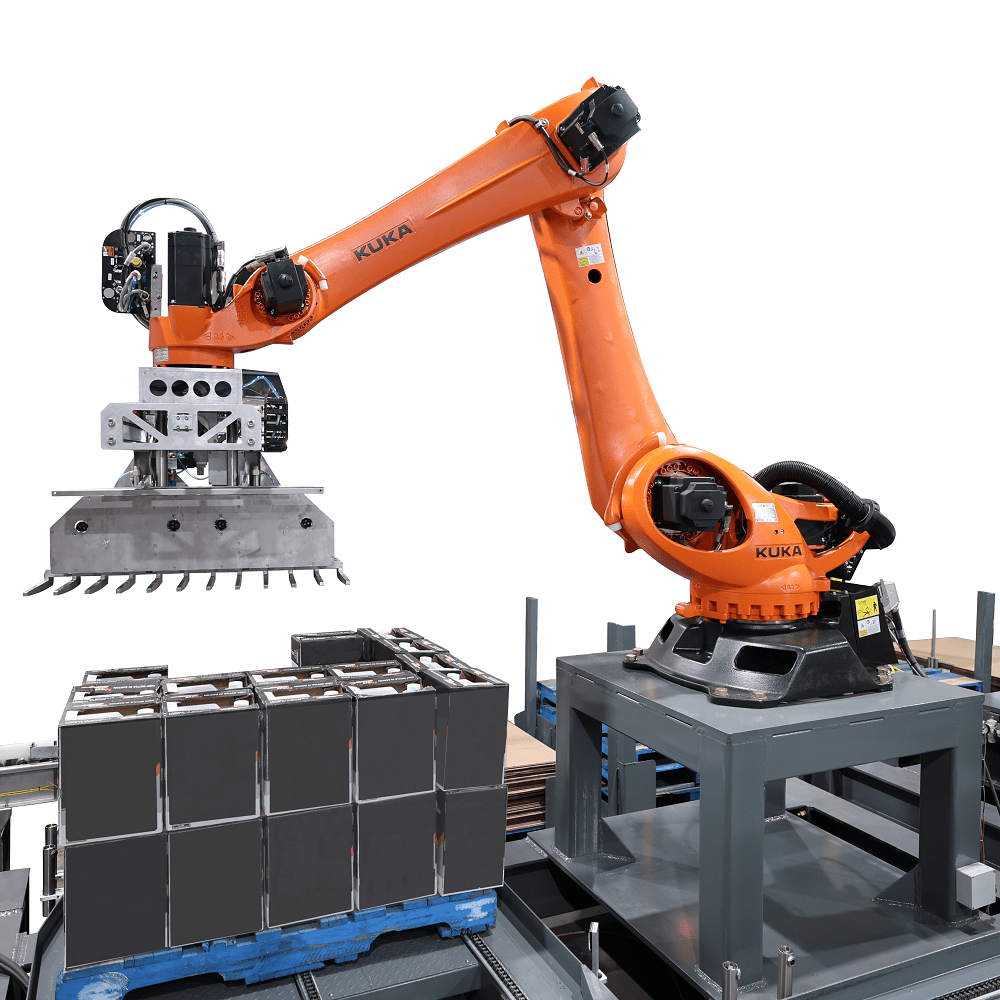

Our industrial palletizing robots are engineered for precision in handling and stacking various packaging formats, including boxes, drums, barrels, pails, jug-in-box, large volume containers, totes, and bags onto pallets. As a leading robotic palletizer manufacturer in Canada, we specialize in providing automated palletizing equipment that ensures efficient and consistent palletization.

Our robotic case packer and palletizer solutions are designed to automate the precise arrangement of sealed boxes onto pallets according to predetermined patterns and specified layer counts. Our high-speed palletizer offers rapid and reliable palletizing for diverse product lines, enhancing efficiency in your packaging processes.

Automatic Bag Palletizer Machine | Automatic Box Palletizer

Discover the versatility of our automatic bag palletizer machine, capable of efficiently palletizing various packaging types, including bags, boxes, and more. The automatic box palletizer seamlessly integrates into your production line, automating the stacking of rigid cases, cartons, barrels, bulky products, bundled products, and mixed-sized packaging.

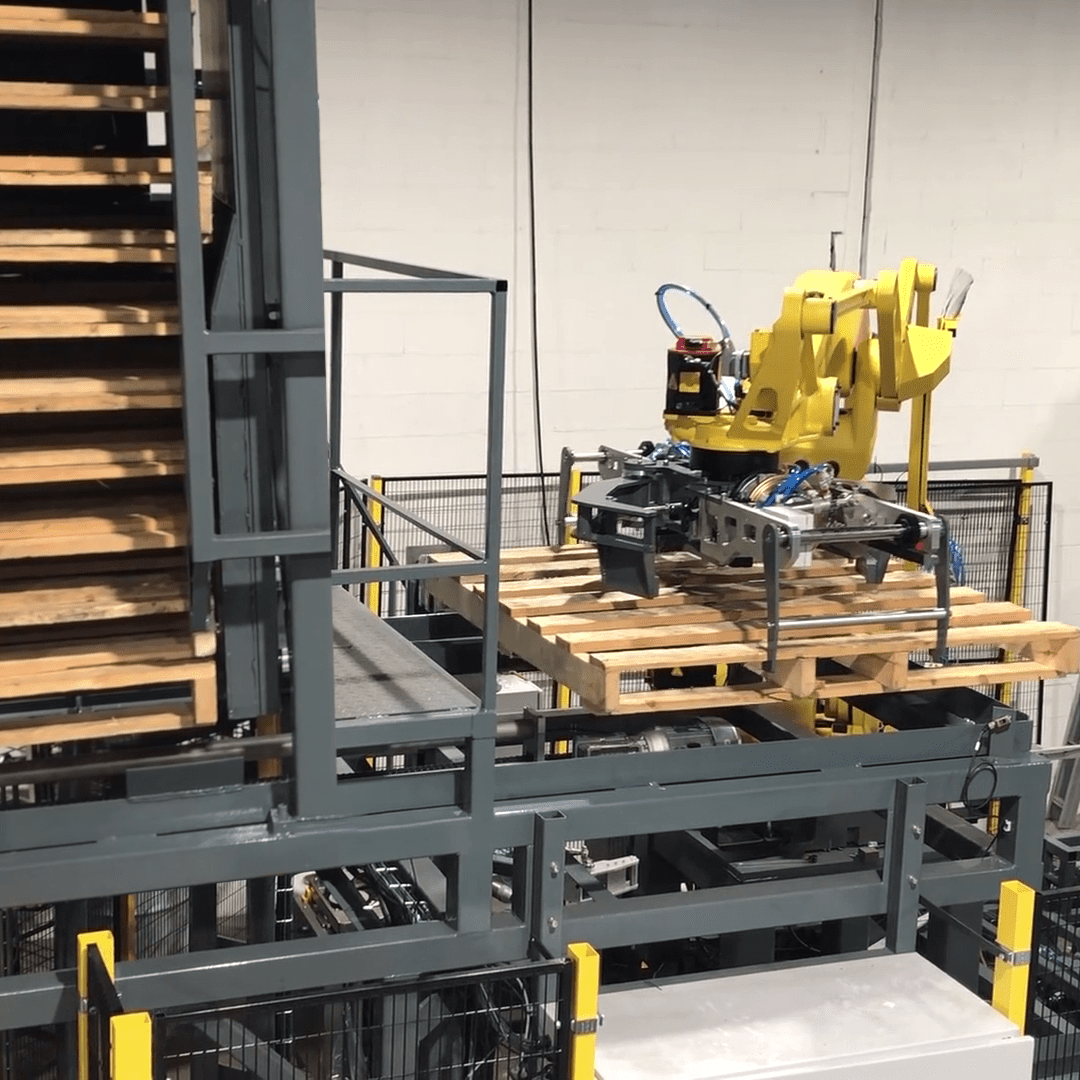

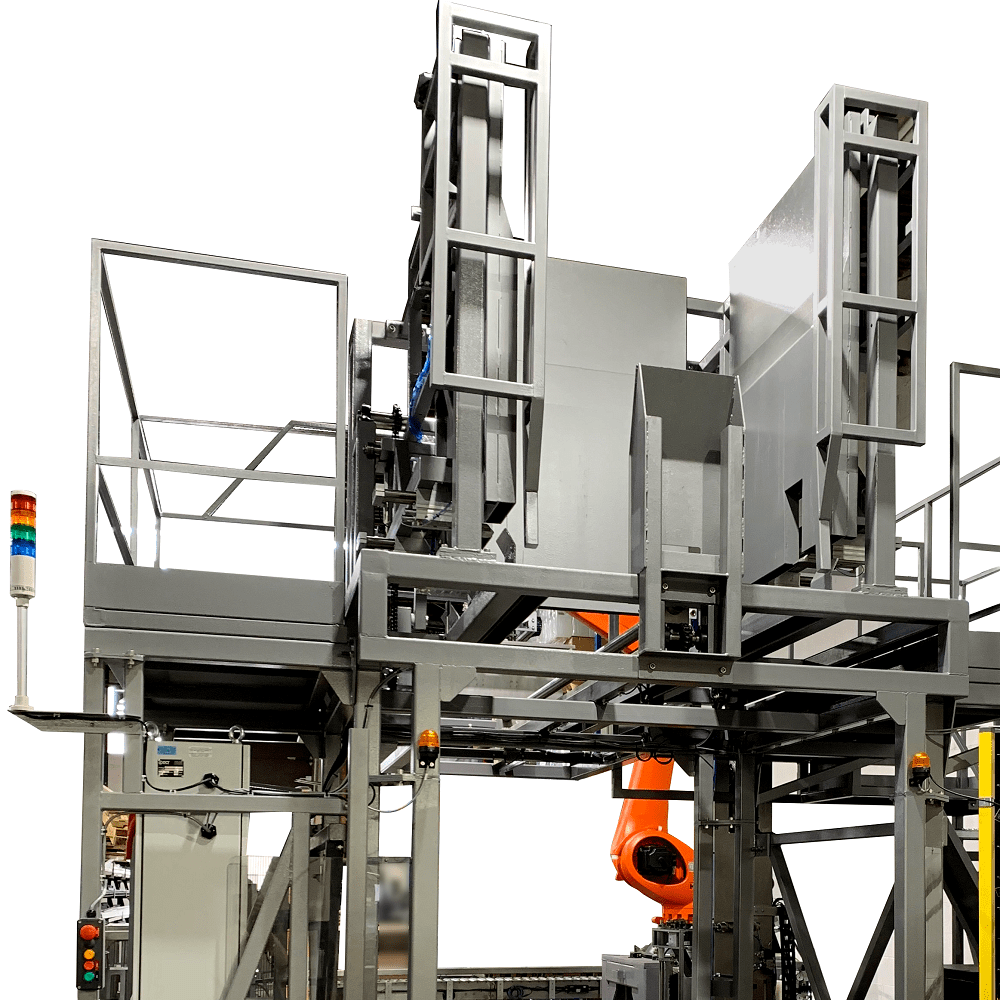

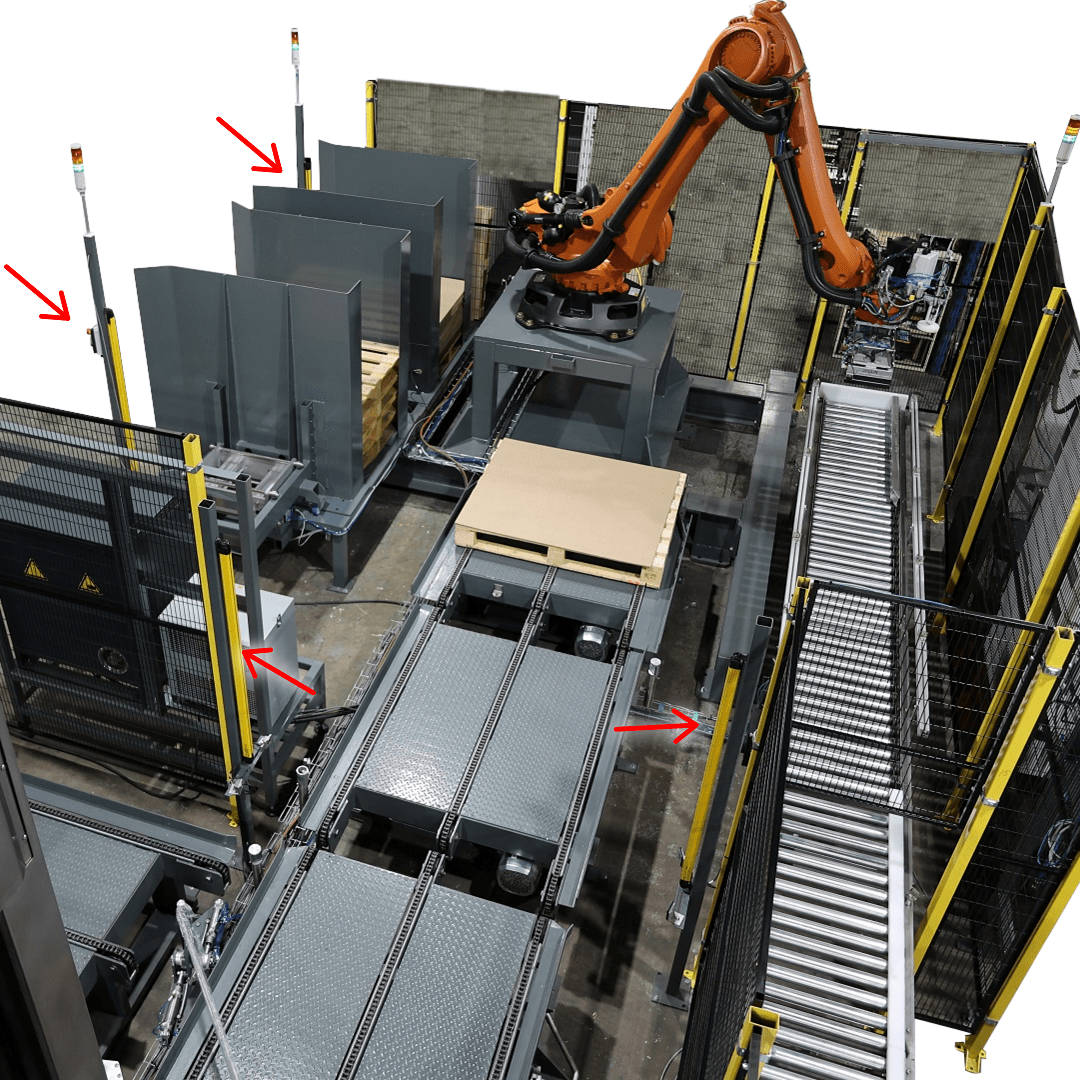

Automatic Robot Palletizing System | Pallet Handling Systems

Our automatic robot palletizing system ensures precise stacking of products according to predetermined palletization patterns. The pallet handling systems, including dispensing, conveying, and orientation units, contribute to a seamless and streamlined packaging process. Choose from mezzanine mount, pallet conveyor mount, or floor mount arrangements to suit your facility's needs.

Features of Our Automated Palletizing Equipment:

- Heavy-duty structural steel frame for smooth and vibration-free operation.

- Load-dispersing frames for robot mounting designed in-house for seamless integration.

- User-friendly HMI interface for automatic product changeover.

- Safety measures include machine guards, security door locks, and light curtains in critical areas.

Enhance your packaging efficiency with our comprehensive range of automatic palletizing solutions, backed by cutting-edge technology and expert engineering.