Our products

Investing in production automation offers substantial benefits, including increased speed, efficiency, and cost savings. At DGT Solutions Inc., we excel in designing and manufacturing customized automatic packaging equipment. Our equipment is adaptable, aligning with the latest technologies and production requirements, and we prioritize continuous improvement based on customer feedback from diverse markets.

Discover the product categories below.

Product Categories

PRODUCTS

Feeding Systems

In-Feed equipment

The feeding systems provided by DGT Solutions Inc. are designed on the basis of product samples provided by customers. Theses feeding systems you achieve the high level of productivity. In addition, these feed systems are also flexible enough to feed multiple types of products into the same feed system or accommodate future product design changes.

Our feeding systems are designed to enable precise and accurate distribution of the product resulting in an efficient and economical automation.

Unscrambling and sorting equipment

In-Feed equipment

Automatic unscrambling equipment including unscrambling, sorting, orienting and conveying container caps to automatic capping machines. Such equipment can be designed to work with any metal or plastic caps, of symmetric and asymmetric shapes.

Conveyor Systems

Processing machines

Our conveyors can be integrated into many systems, including existing production lines. In general terms, conveyors move products, containers, cases, totes or pallets from one location to another on straight or curved paths. Products can range from small, lightweight products to large, heavy parts. Our conveyor systems can be customized to meet your production line dimensions and operating requirements.

DGT Solutions Inc. manufactures a wide range of conveyors for a variety of conveying solutions:

- Belt conveyors

- Chain conveyors

- Roller conveyors

- Inclined conveyors

Bagging Machines

Processing machines

Industrial bagging equipment manufactured by DGT Solutions Inc. are suitable for different bag types. Whether it is a wicket type bag, a regular plastic bag or a Zip-Lock bag, we can provide you with a flexible and easy to use machine to speed up your production.

Decapping machine

Processing machines

Our Bottle | Container Decappers pick the caps from the guide tracks, untwist, detorque and remove caps from empty bottles prior to filling or washing of bottles. Our Decapping Machines can work with a wide range of different container shapes, sizes and materials, plastic or glass.

Bottle Cleaning

Processing machines

Our bottle cleaning machines | washing machines use compressed air to clean containers from dust or debris prior to filling. The bottle cleaning machines use nozzles to blow a stream of air into each container. Our bottle cleaning machines can work with a wide range of different container shapes, sizes, and materials, both plastic and glass.

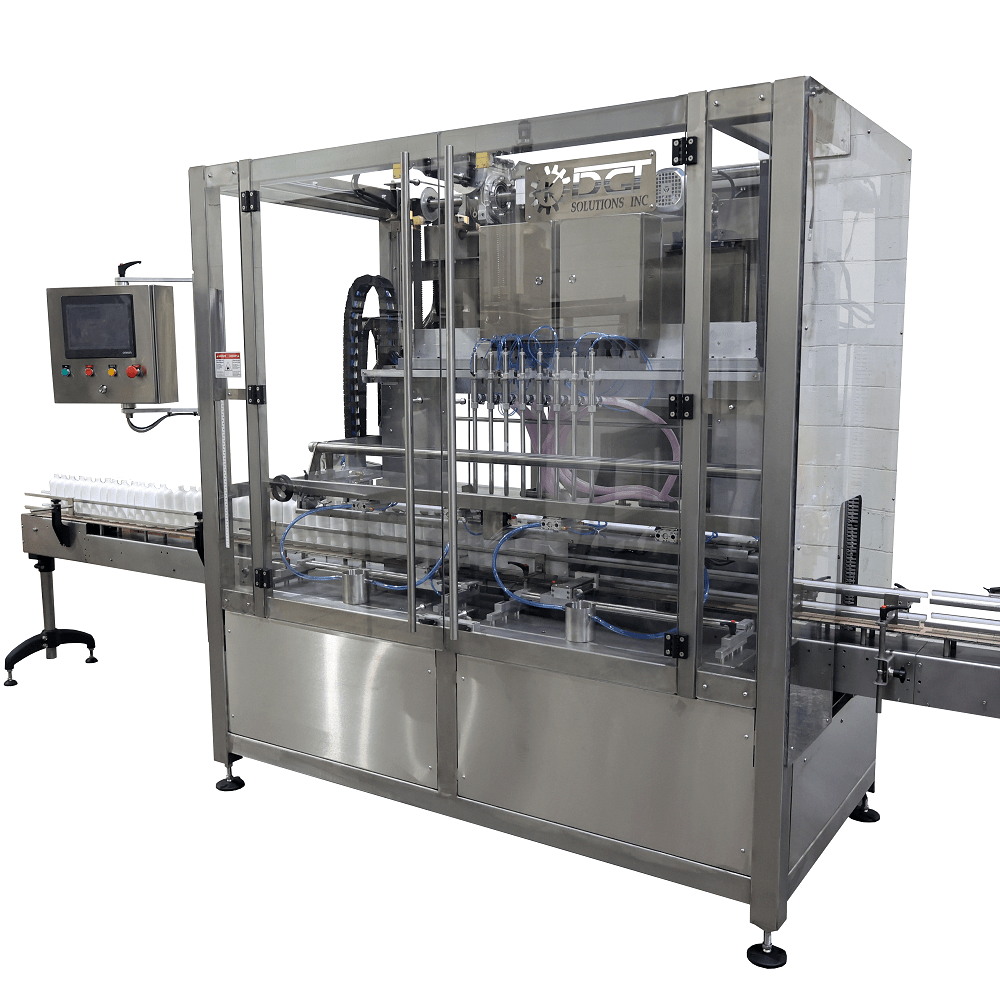

Liquid Filling

Processing machines

Liquid filling machines provide high-speed liquid filling of various liquid types into various container shapes and sizes. Our machines have excellent filling precision and repeatability across a range of volumes and product viscosities. They are made to best suit your needs, while ensuring superior product quality, minimized product waste and required production speed. Whether it is a plastic or glass bottle, a can, a bucket, or a pail, we will find the best filling solution for you.

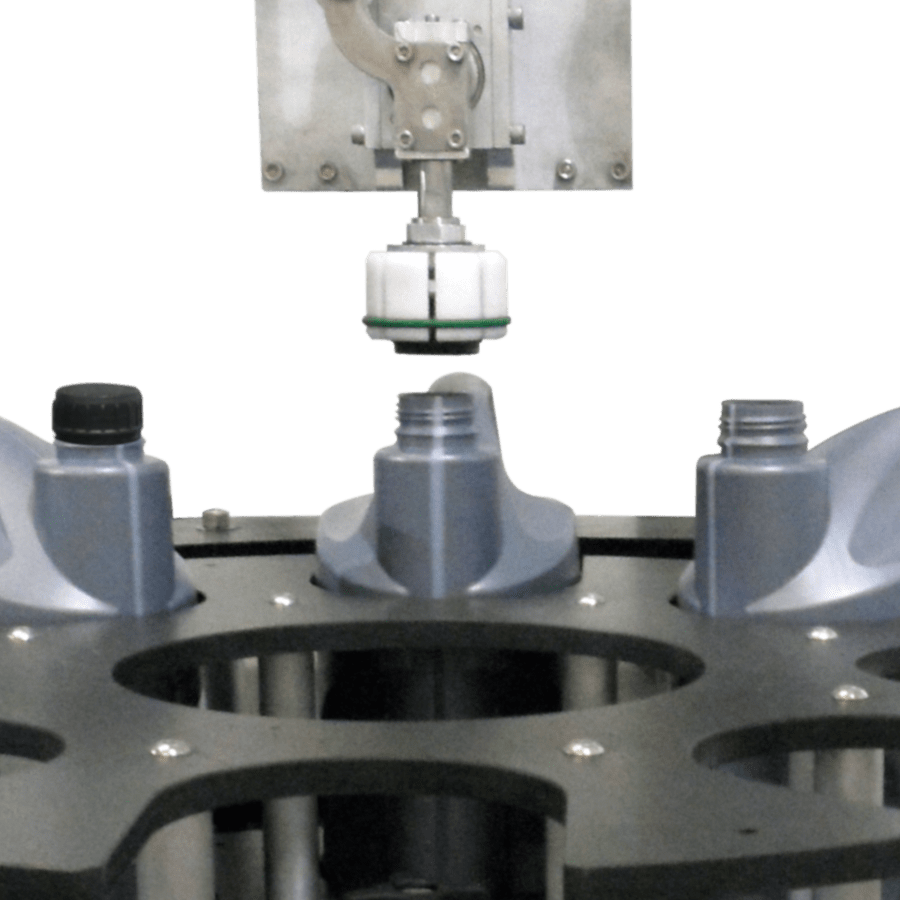

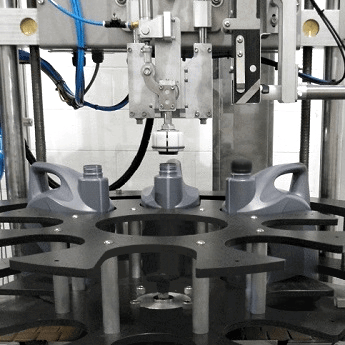

Container Capping

Processing machines

n automatic capping machine is made to individual specifications to perform feeding, orienting and applying caps or lids to the bottles or containers. Custom-made cappers ensure that your containers or bottles will be capped and torqued consistently. They have great flexibility with their electronically controlled, easily configurable, adjustable, parameters for rotation, twisting force and container height. Filling and capping can be performed in a single automatic filling and capping machine.

Labeling Machines

Processing machines

Our labeling equipment performs the application of self-adhesive labels onto cans, glass bottles, plastic bottles, buckets, pails and other types of containers of all shapes and sizes. Bags labeling is also available. These labeling machines may be simply integrated into an existing production line or be operated as a stand-alone solution.

Box Formers

Packaging machines

Box formers | case forming machines automatically form, fold and seal corrugated boxes and applicable to a wide range of box sizes. Due to the ergonomic design of box formers manufactured by DGT Solutions Inc., they can be used for packaging areas with a restricted floor space providing a compact case former and packing station. Our box formers are built for heavy usage with a quick and easy case size changeover adjustment.

Box Sealing Systems

Packaging machines

The two main material choices for boxes, cases or cartons sealing applications are hot melt adhesive and adhesive tape.

- Hot melt adhesive is a synthetic resin that becomes liquid when heated, it is applied using the automatic hot melt adhesive equipment with one or multiple applicators.

- Adhesive tape is a pressure sensitive plastic or nylon-reinforced filament where a polymer is usually the main adhesive element.

Depending on your application and requirement, we will find the best sealing solution for your boxes, cases, or cartons.

Cartoners

Packaging machines

A cartoning machine or a cartoner is a packaging machine that picks up cartons from flat cardboard blanks, folds them and fills them with a rigid product, or a bag with the product or the number of products. The loading can be semi-automatic or fully automatic. After loading is completed, the complete cartons are closed and/or sealed. Our cartoning machines are ideal for packing flow-wraps, pouches, bags, thermoformed trays, blisters jars and more. The machine can be optimized for tuck-in closing or melt sealed with hot melt glue.

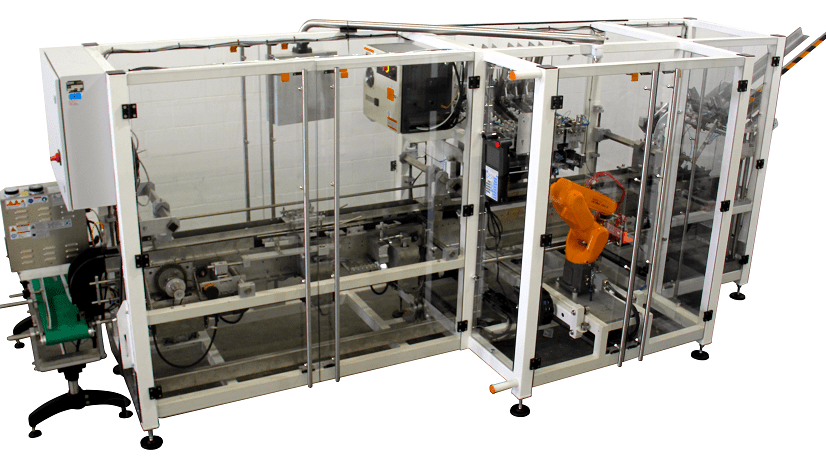

Case Packers

Packaging machines

Our Case Packing Machines are configured and designed to match your product geometry. The case packing equipment, traditional case packers, and robotic case packing machines, can handle all your case all your packing needs via an automated process. The machine automatically grips, moves, and packs your product into cases or boxes. The box is then automatically closed and sealed.

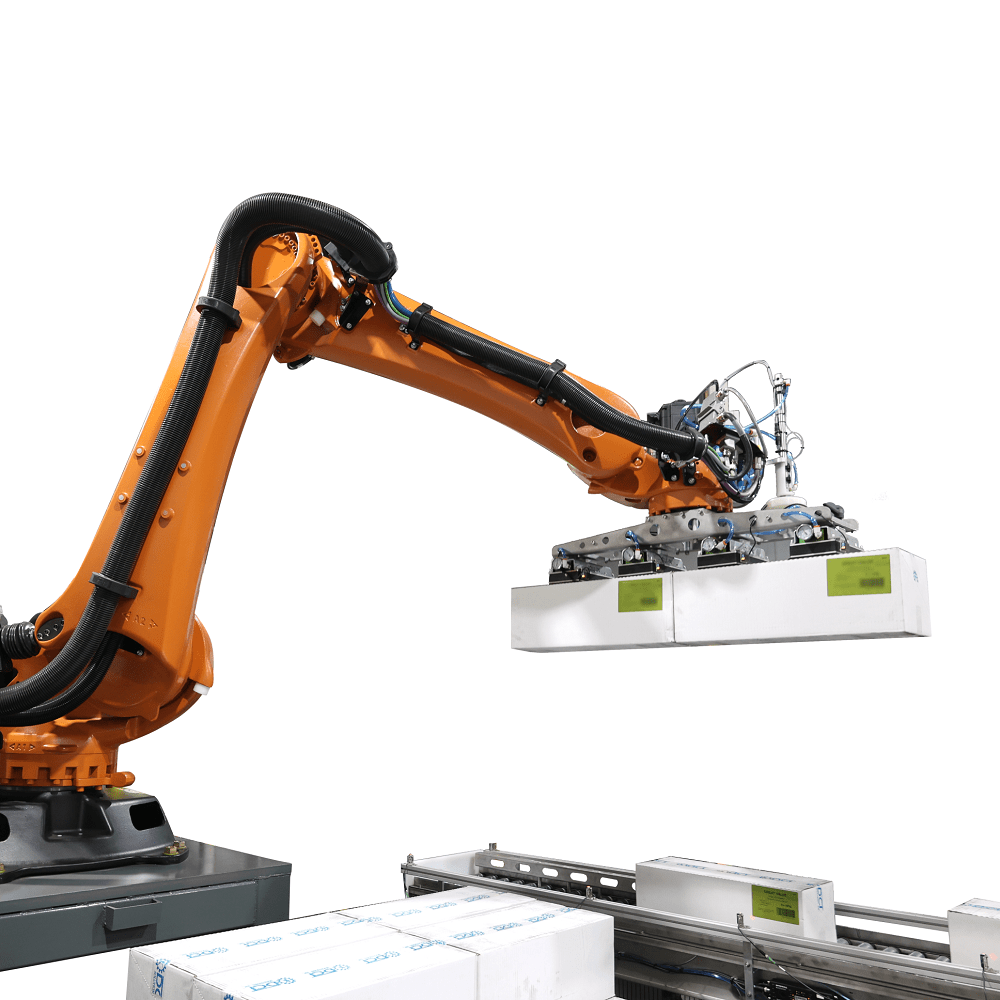

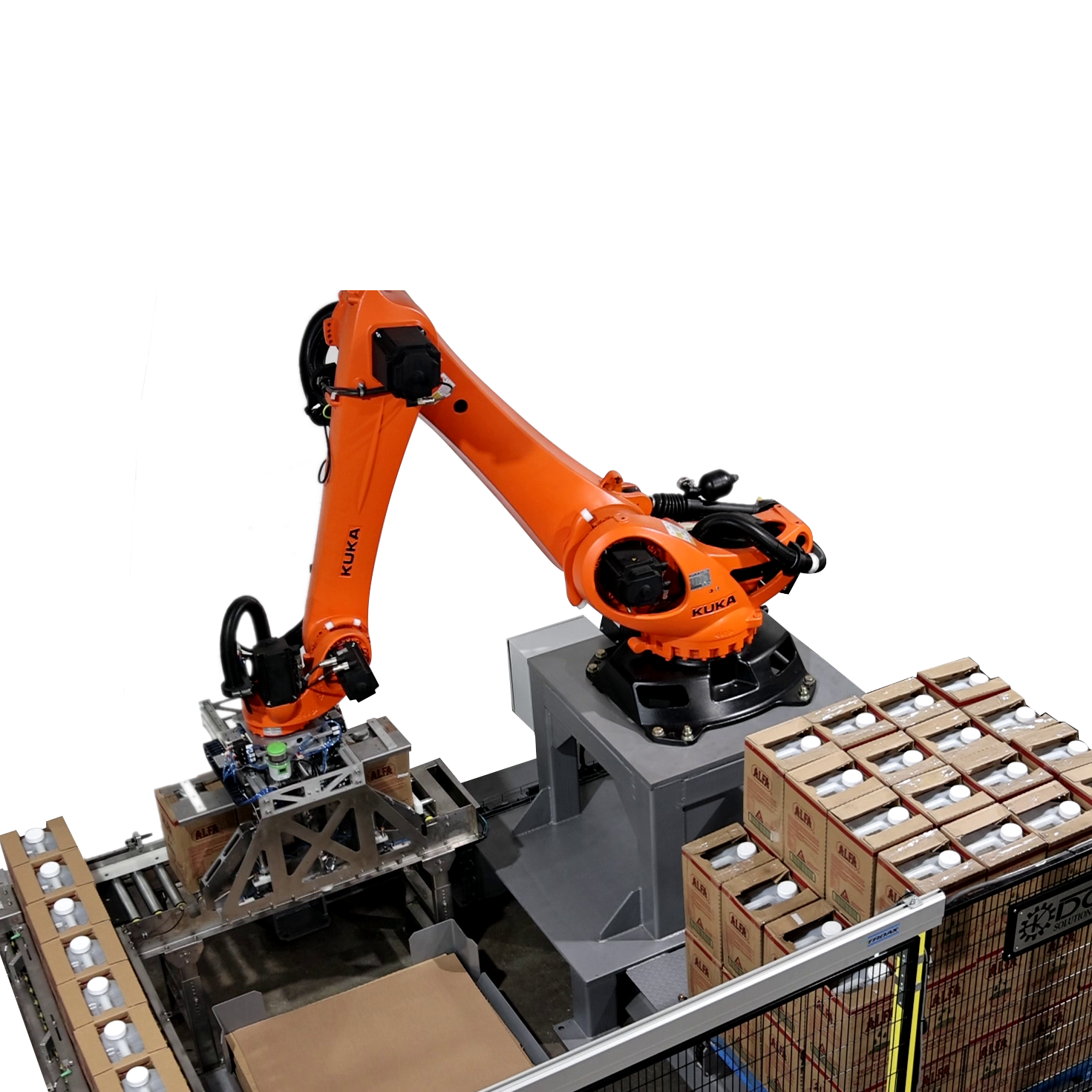

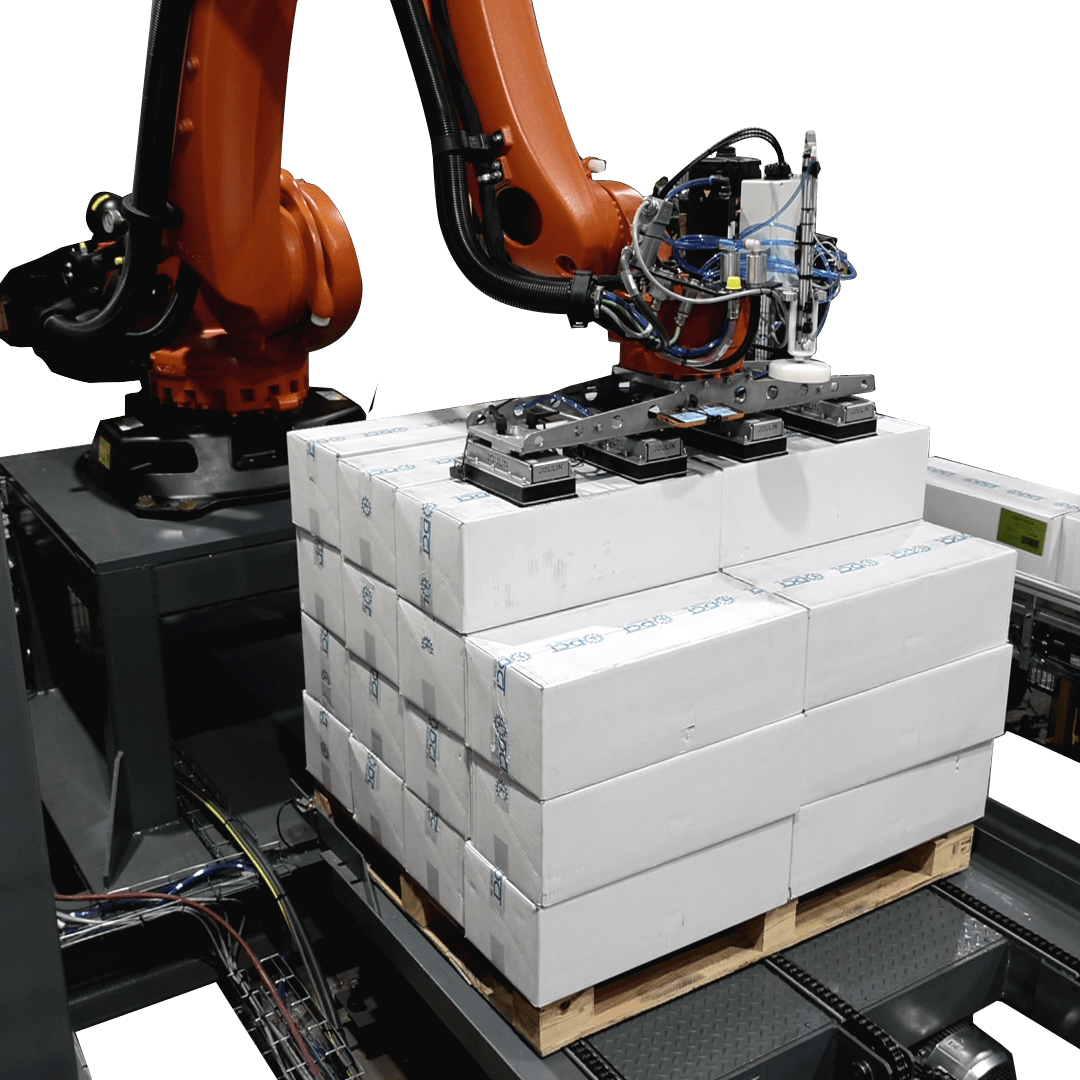

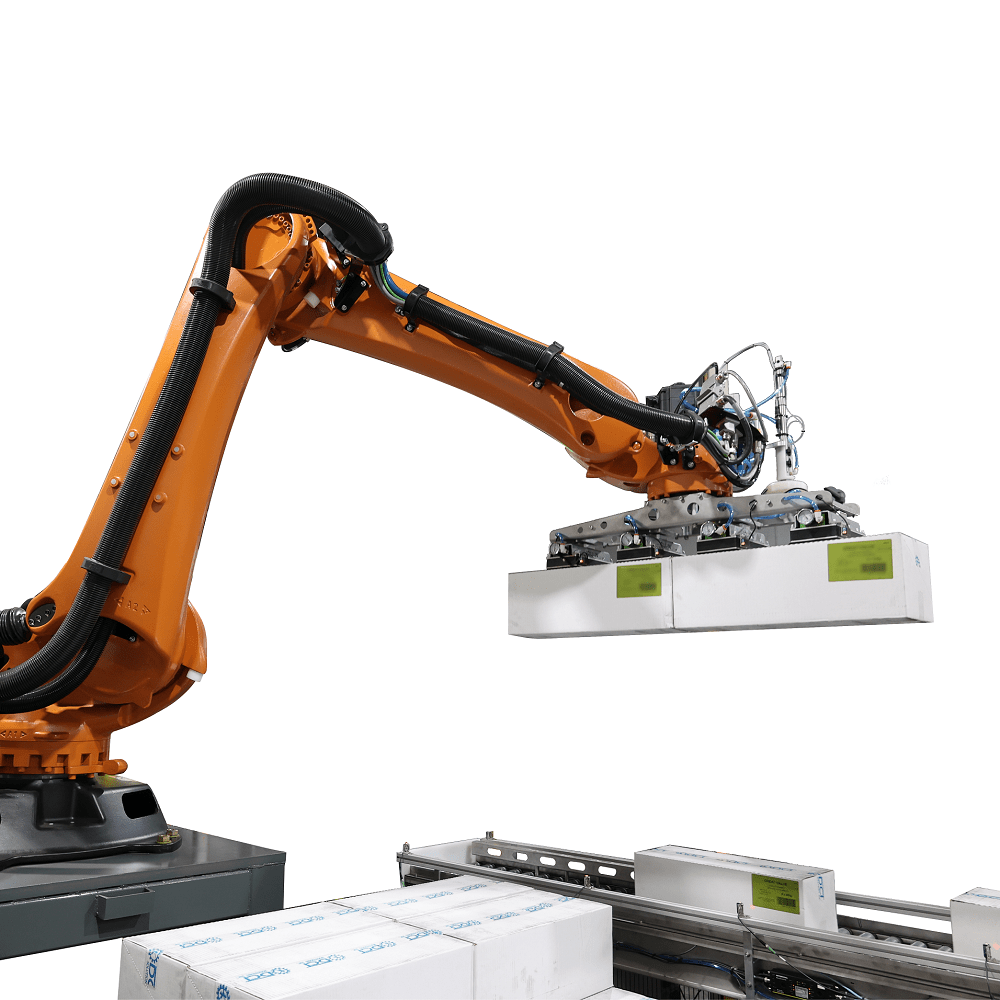

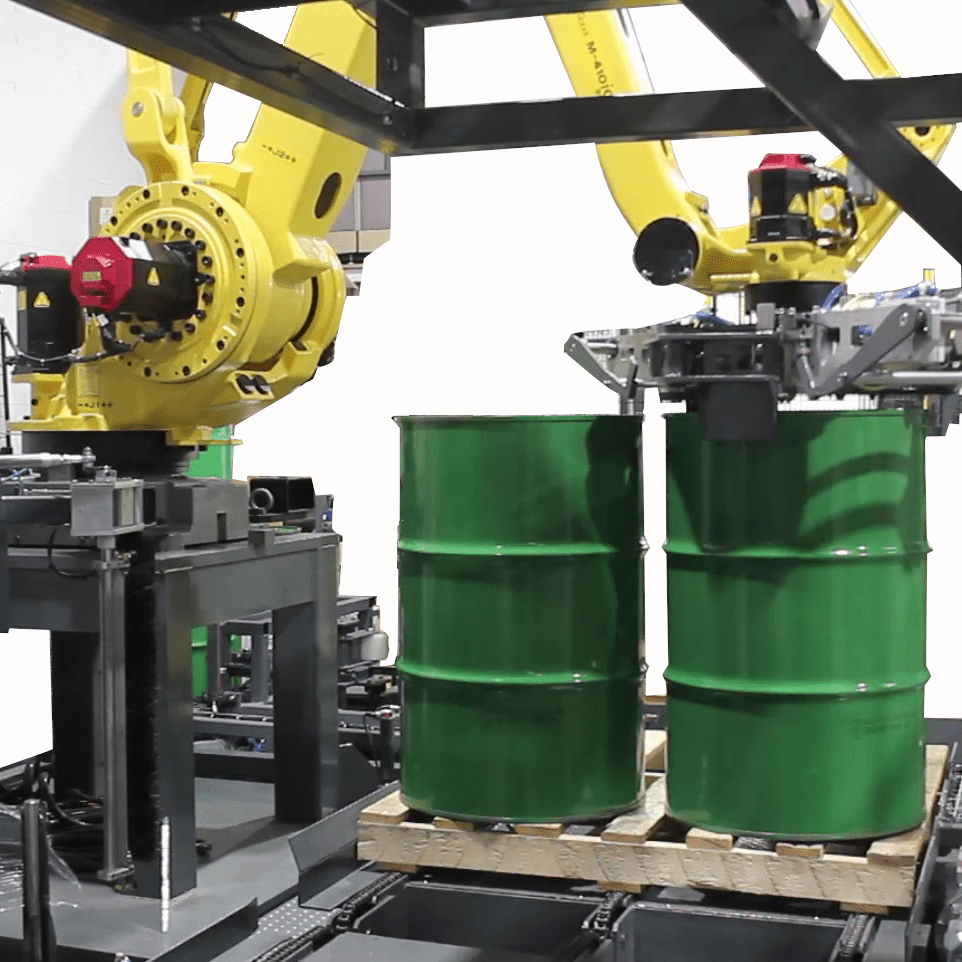

Automatic Palletizers

Packaging machines

The automatic palletizing machine is built to perform automatic sorting, transferring and stacking of boxes, bags, drums, barrels, pails, jug-in-box, large volume containers, totes, or flexible packaging, onto a pallet, followed by pallet wrapping with stretch film.

Shrinkable sleeve machine

Packaging machines

The heat shrinkable plastic sleeve can cover the entire container or just a part of it. After applying the sleeve onto the products the sleeve has to be shrunk using hot air tunnel. The sleeving machines for heat shrinkable plastic can be linear and rotary machines.

Carton Sleeve Machine

Packaging machines

The Automatic carton sleever machine is designed to perform putting the sleeve on the product. In the automatic carton sleever machines, product can be fitted within a cardboard sleeve in either of two ways: the product packaging is slid into the sleeve, or the sleeve is folded around the product packaging and then sealed.

Wood-cutting machine

Other equipment

One of examples of custom-made machinery built by the DGT Solutions Inc. is Wood Cutting machine. It can be useful to make fundamental improvements in your productivity and minimize wood waste when cutting. Our Wood Cutting machine enables you the highest performance for even higher productivity and profitability. Our machines ensure maximum stability, comprehensive safety concept and productivity — even with extreme loads.

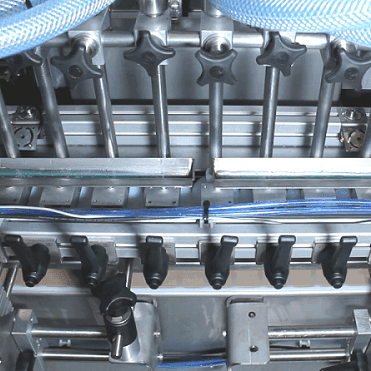

Tooling

Other equipment

Many containers or bottles are irregularly shaped or unstable when moving on a conveyor line. The faster the conveyor line runs, even perfectly round bottles become more unstable. Not precise movement of containers results in downtime and lost profits. DGT Solutions Inc. has mastered the “art” of precise container and bottle handling with many specialized designs of starwheels and guide profiles (I-frame or central pieces) which can be exchangeable for individual bottle sizes so our bottle handling system can handle just about any container shape.

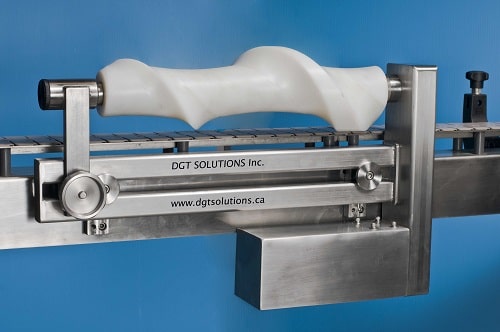

Bottle spacers

Other equipment

Bottle spacers or feed screw systems are used mainly to separate containers or bottles for proper filling, capping and labeling to maintain proper spacing between containers that like to jam together on a moving conveyor. Our feed screw systems manufactured from premium materials for low friction and custom container geometry profile and are specifically designed to keep containers or bottles (oval, square or irregularly shaped) upright and stable in a moving packaging line.

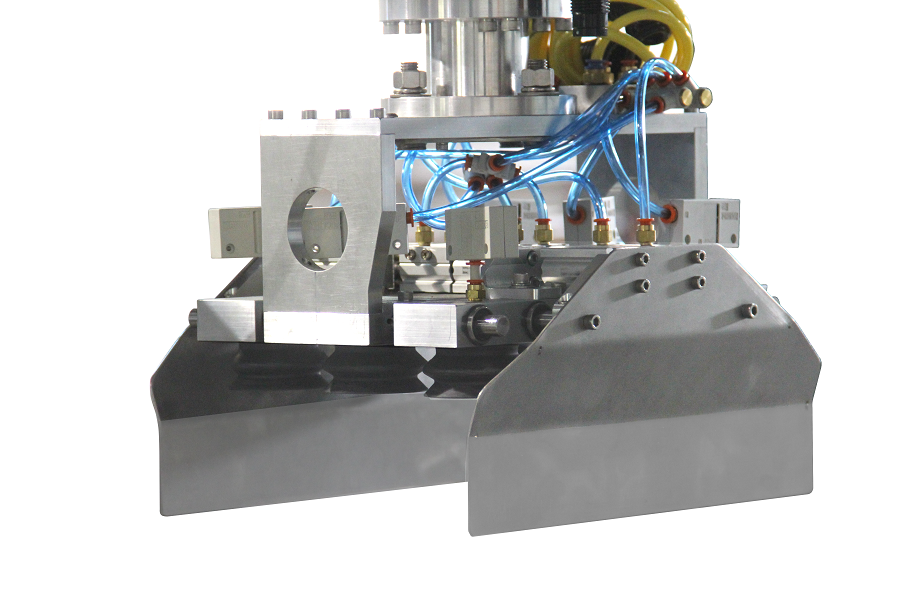

Gripping systems

Other equipment

From standard to custom-designed grippers — use our expert knowledge in selecting and designing successful product handling solutions. Our gripping systems are designed to handle any type of product in the most efficient way. For the bulky and rigid product or a small and fragile product, we can design the gripping system to meet your requirements.