Rotary Liquid Filling Machines

Processing machines

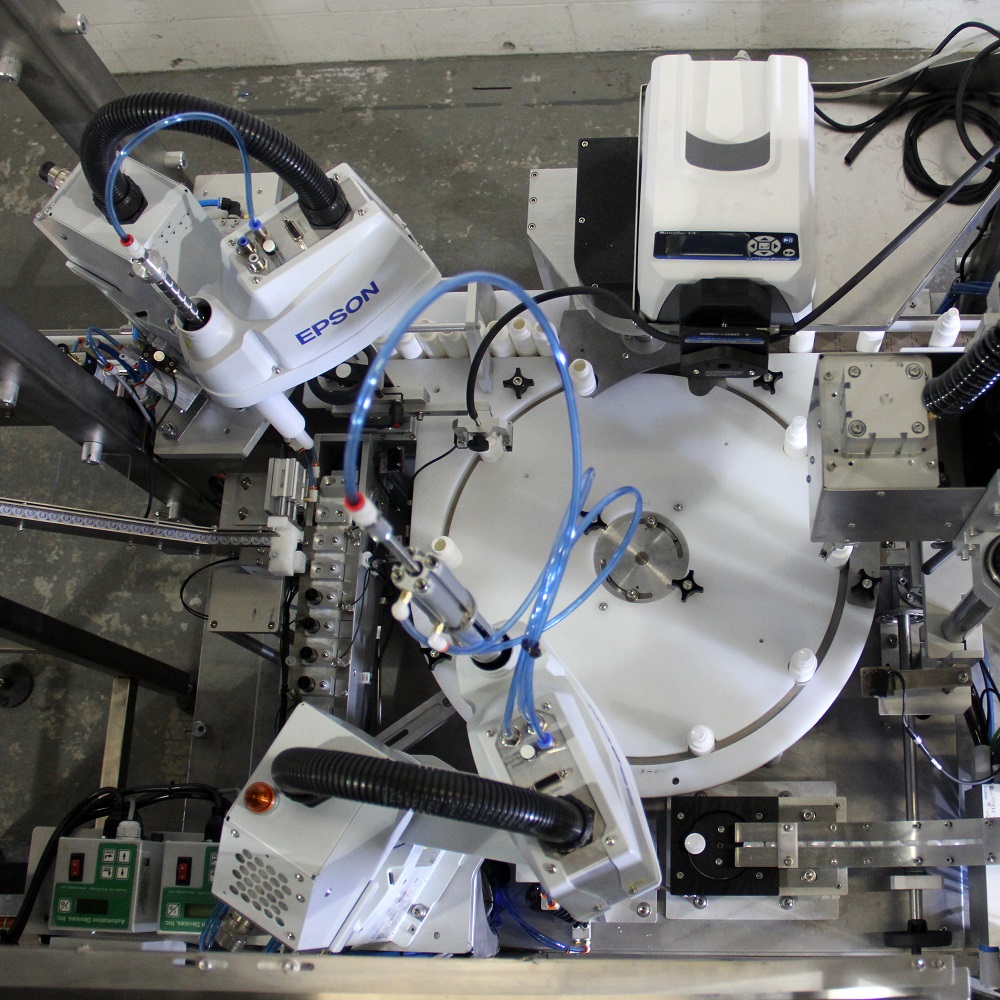

Rotary liquid filling machines can handle large-scale and high-speed filling production. In this type of machine, the containers are moved around circular stations, where specific functions such as filling, capping (cap placement and cap re-torque), sealing, sleeving, etc. are performed. Compact, fast, flexible, and reliable, our rotary liquid fillers are automatic machines that can adapt to a wide range of containers and products of most viscosities at high production speeds.

Request A Quote