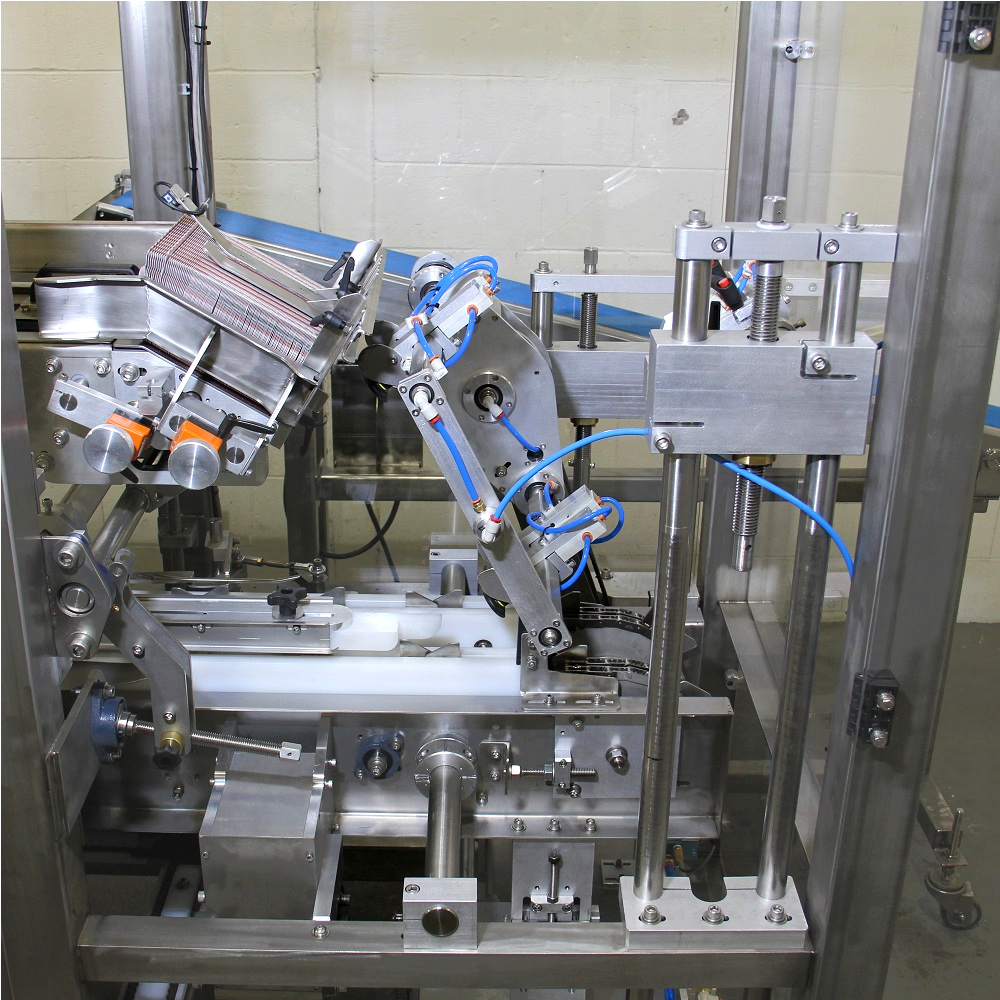

Semi-automatic cartoning machine with safety seal labeler

Packaging machines

This cartoning machine is designed to perform automatic carton pre-forming, manual loading of a product (such as a chocolate bar) into the carton by the operator, followed by automatic carton closing. At the output of the machine, the safety seal application is performed by the labeling machine.