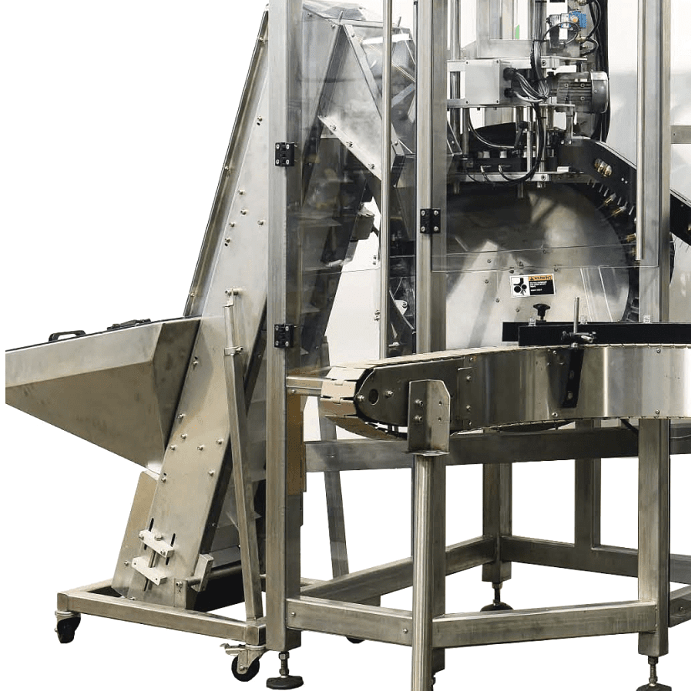

Unscrambling and sorting equipment

In-Feed equipment

DGT Solutions develops and produces unscrambling systems for a wide range of processes: feeding, transferring, guiding, arranging, positioning, separating, lifting, sorting to enable their subsequent handling and packing. Unscrambling systems receive the products in bulk, place them in the required position and supply them to the following stage of the production process at the speed and necessary rate for optimal functioning of the process.

It is possible to integrate measuring and weighing equipment into the feeding systems.

Unscrambling equipment can be rotary (centrifugal), vibratory, vertical waterfall conveying system.

Possible options (or their combinations):

- Feeding

Conveying of containers caps with waterfall elevating system when caps are supplied in bulk

- Orienting

Orienting containers caps in the correct position for efficient cap application on containers

- Sorting

Caps that are not correctly positioned, do not enter the output chute of the equipment

- Rejecting

Sorting and removing containers with defects

Waterfall cap orienters use inclined belts with and the "center of gravity" principle to properly align caps and then supply them via a single file cap chute to the capping machine.