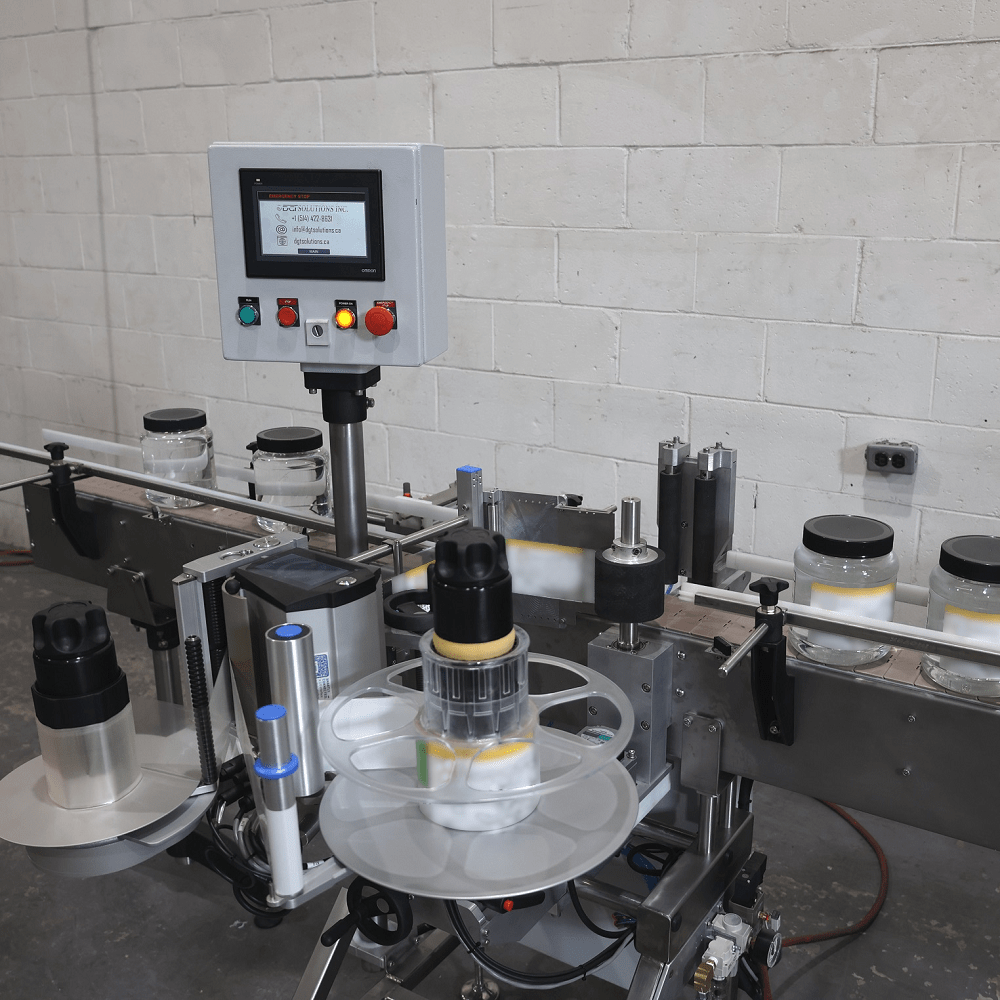

Labeling machines

Automatic wrap-around labeling system is ideal for applying wraparound labels to cylindrical containers, bottles, cans, jars, made of plastic, glass or metal. The container may be fully or partially wrapped with the label along the circumference of the container.