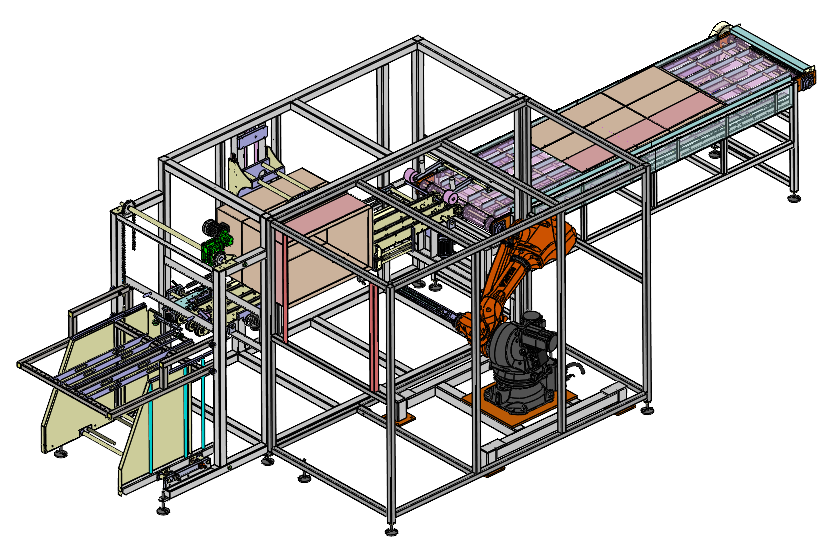

Automatic box cutter machine

Packaging machines

A box cutting machine automatically cuts blank box corners to create box flaps. The distance between box corner slots and slot depth is adjustable. A robot with a robotic arm having a movable knife makes four cuts at all four corners of the box.