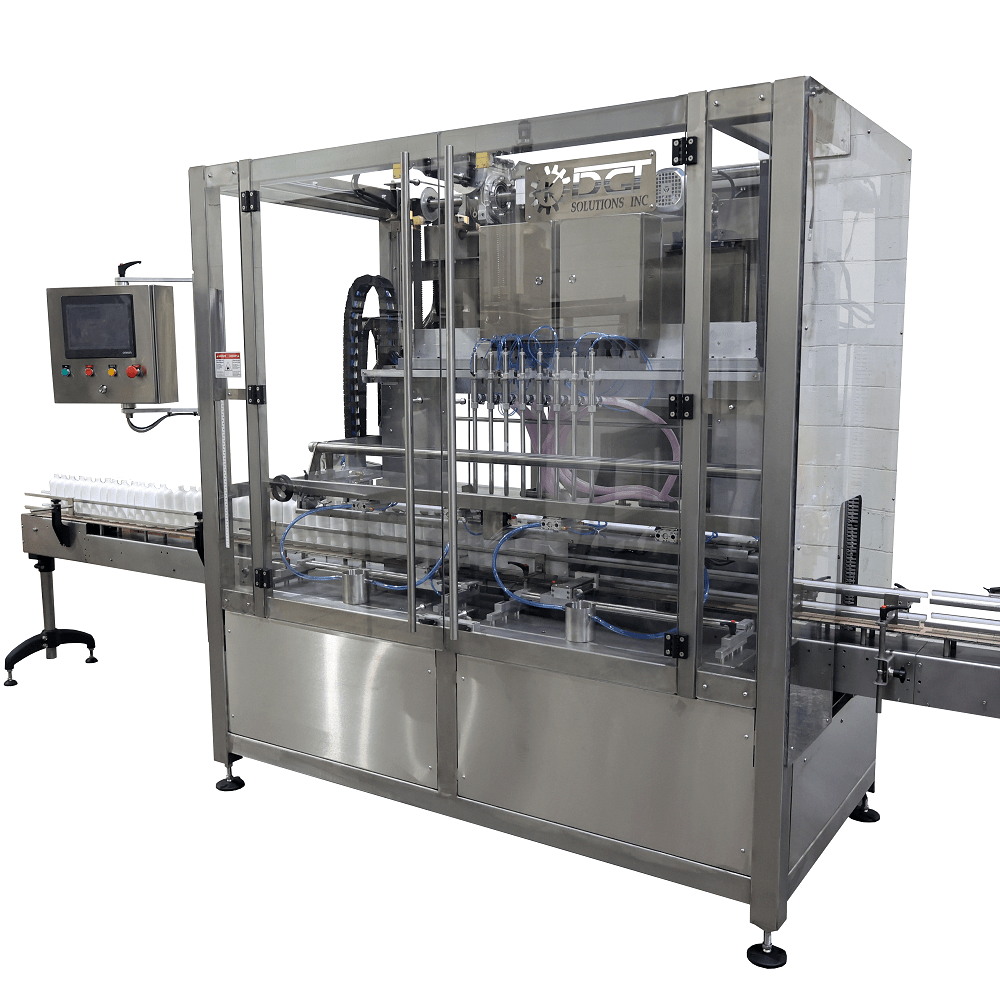

INNOVATIVE AUTOMATION SOLUTIONS

Your premier partner for packaging and automation solutions

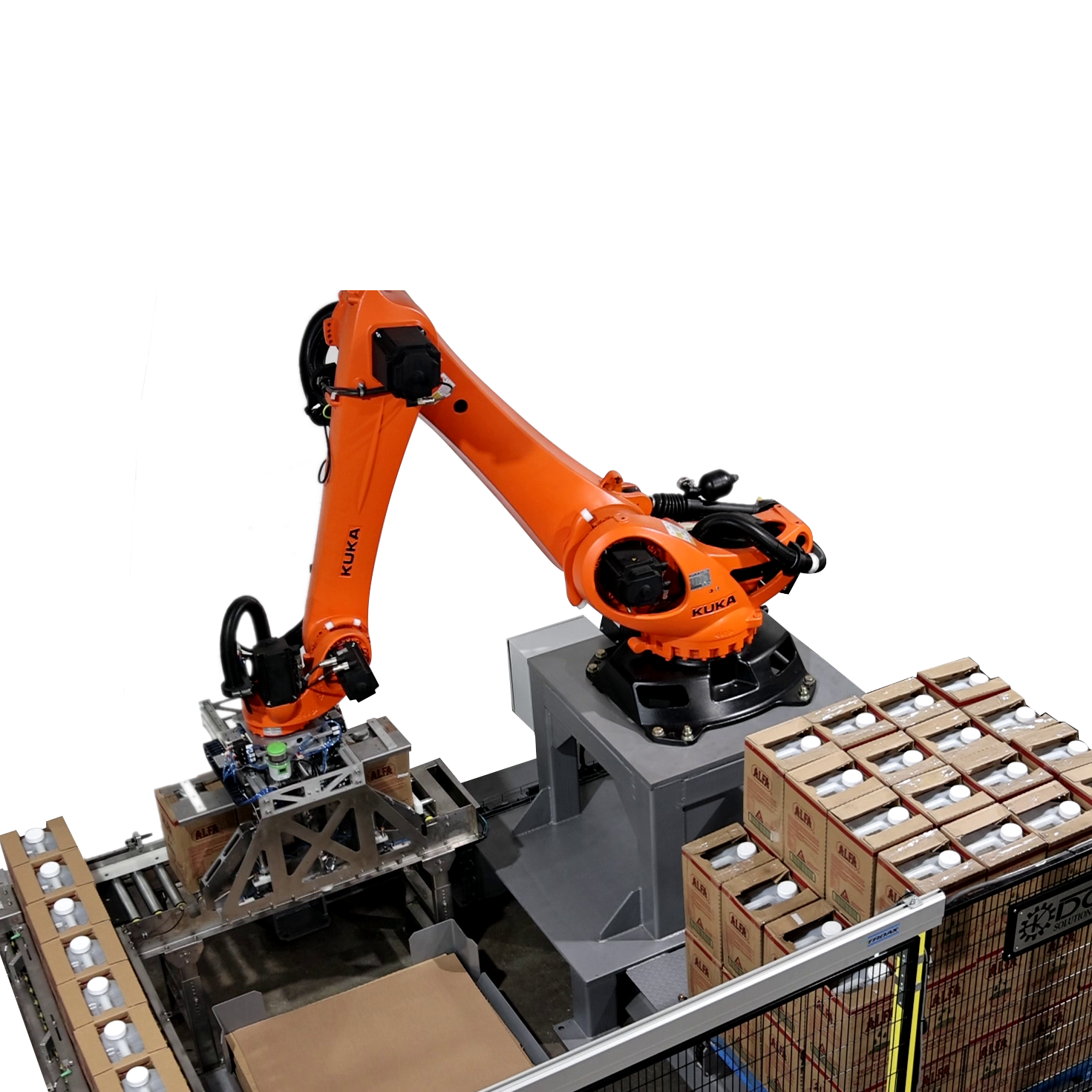

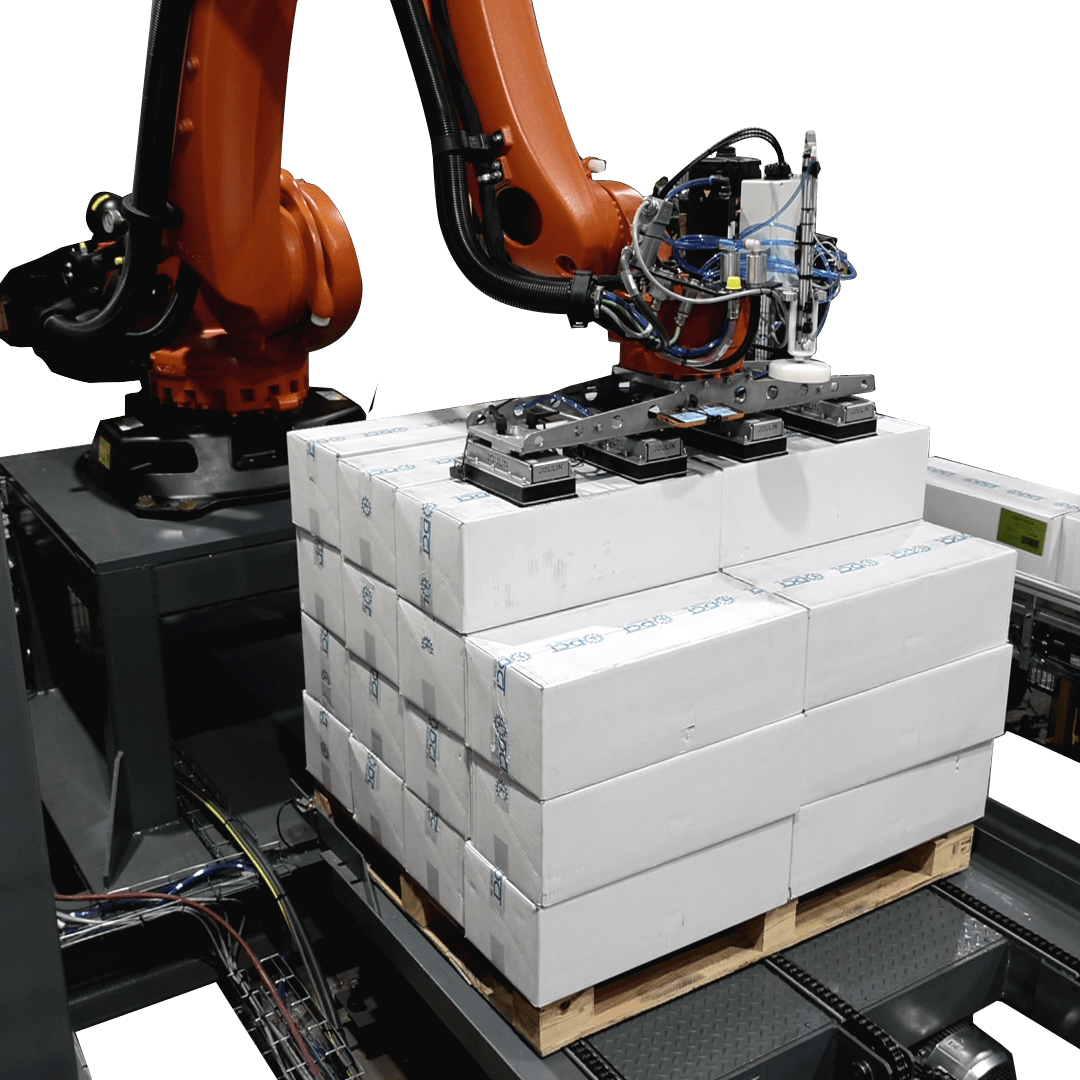

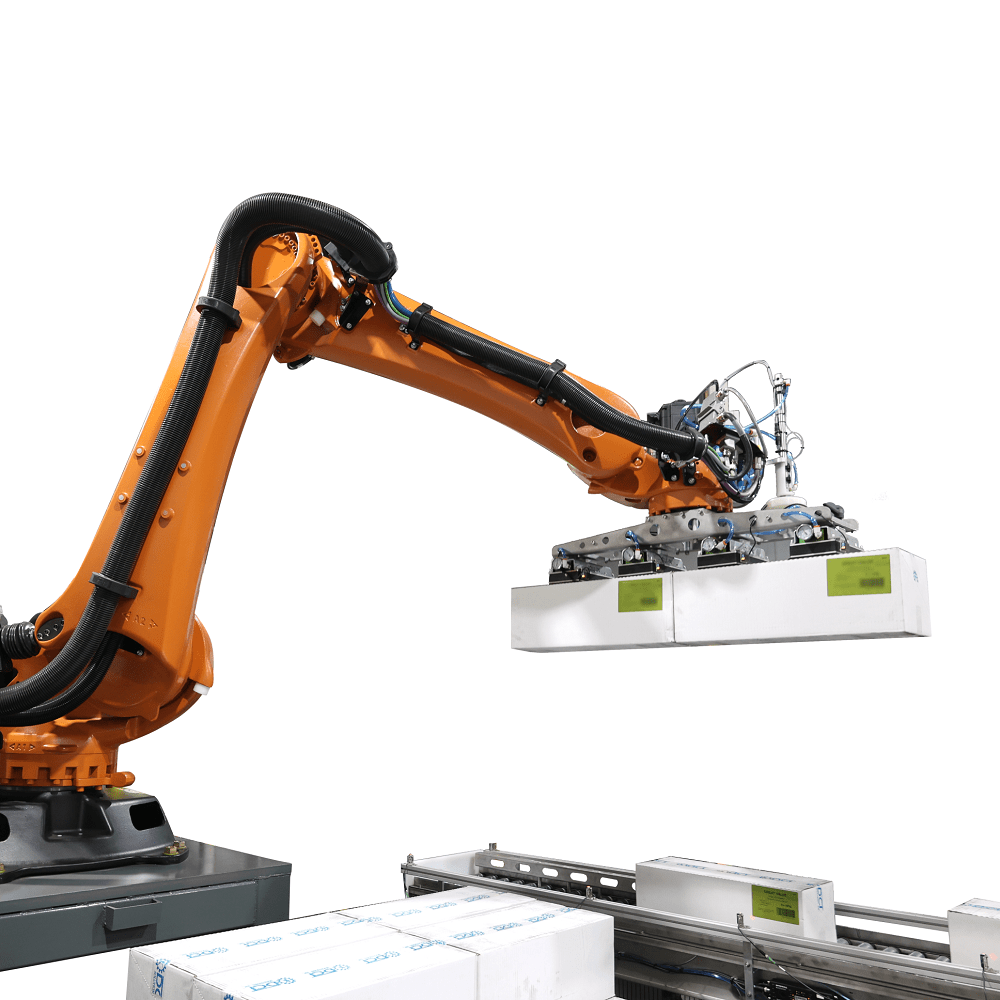

As an official system partner of KUKA Robotics, we provide turn-key solutions to our customers and a true "A-to-Z" response to our customer's automation needs. DGT Solutions Inc. continues to successfully integrate equipment with KUKA Robotic units in a variety of production operations.