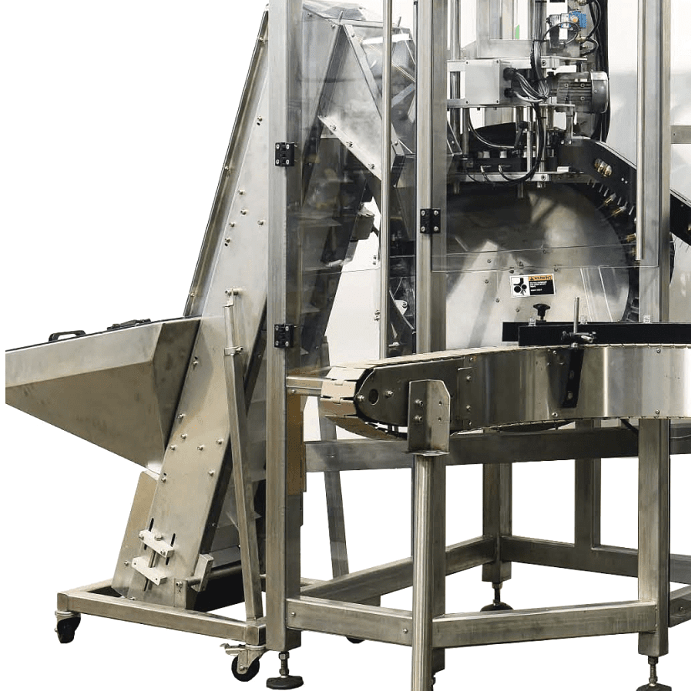

Feeding Systems

In-Feed equipment

DGT Solutions develops and produces feeding systems for a wide range of processes: feeding, delivering, guiding, arranging, positioning, separating, lifting, sorting to enable their subsequent handling and packing. Feeding systems receive the products in bulk, place them in the required position and supply them to the following stage of the production process at the speed and necessary rate for optimal functioning of the process.

It is possible to integrate measuring, weighing and test equipment as the component of the feeding system.

Request A Quote