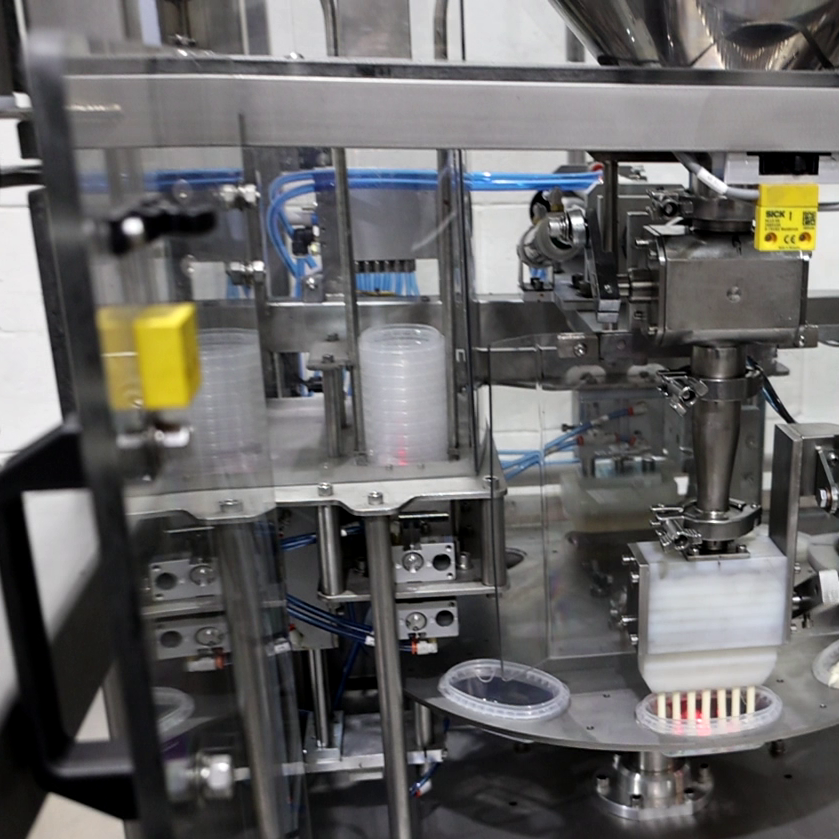

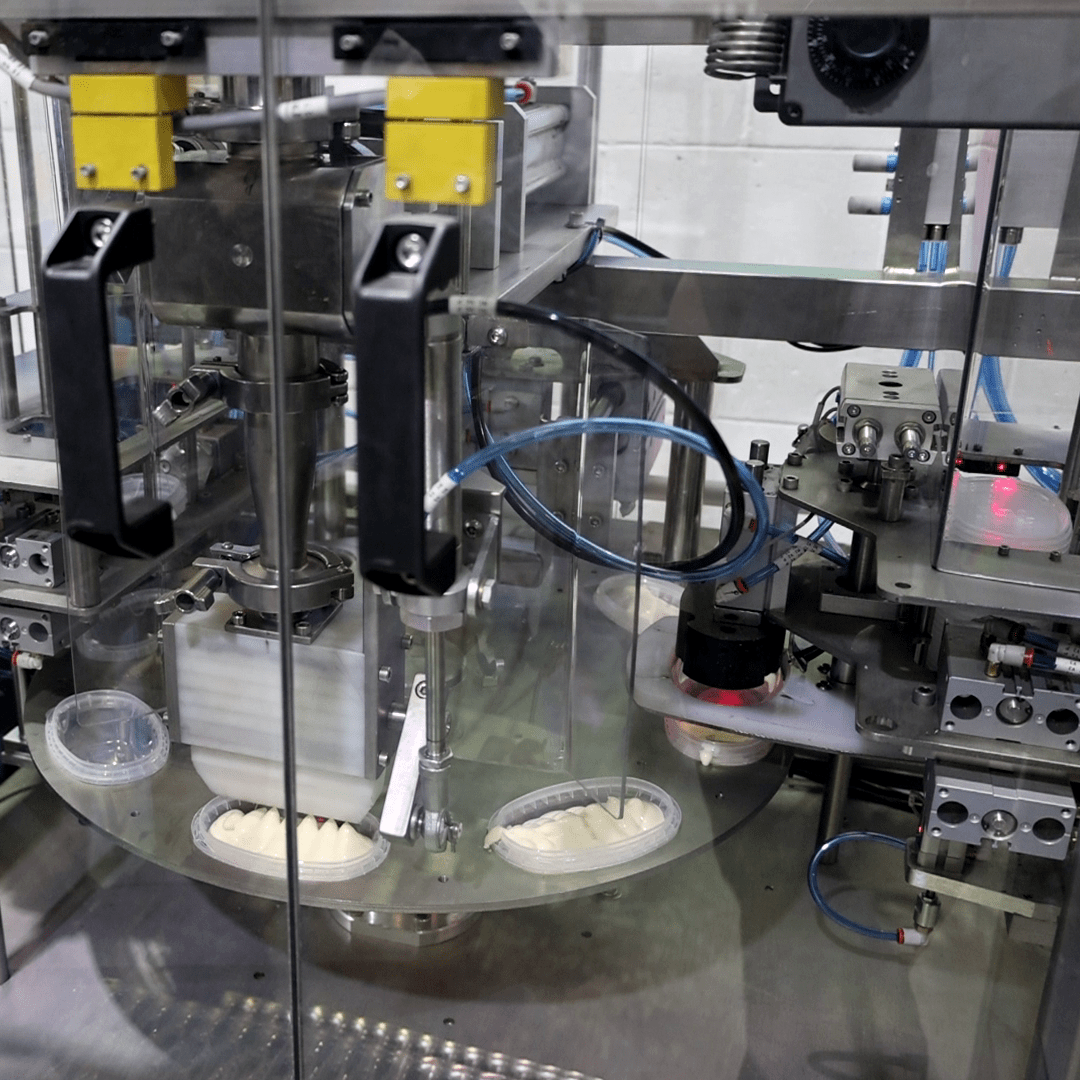

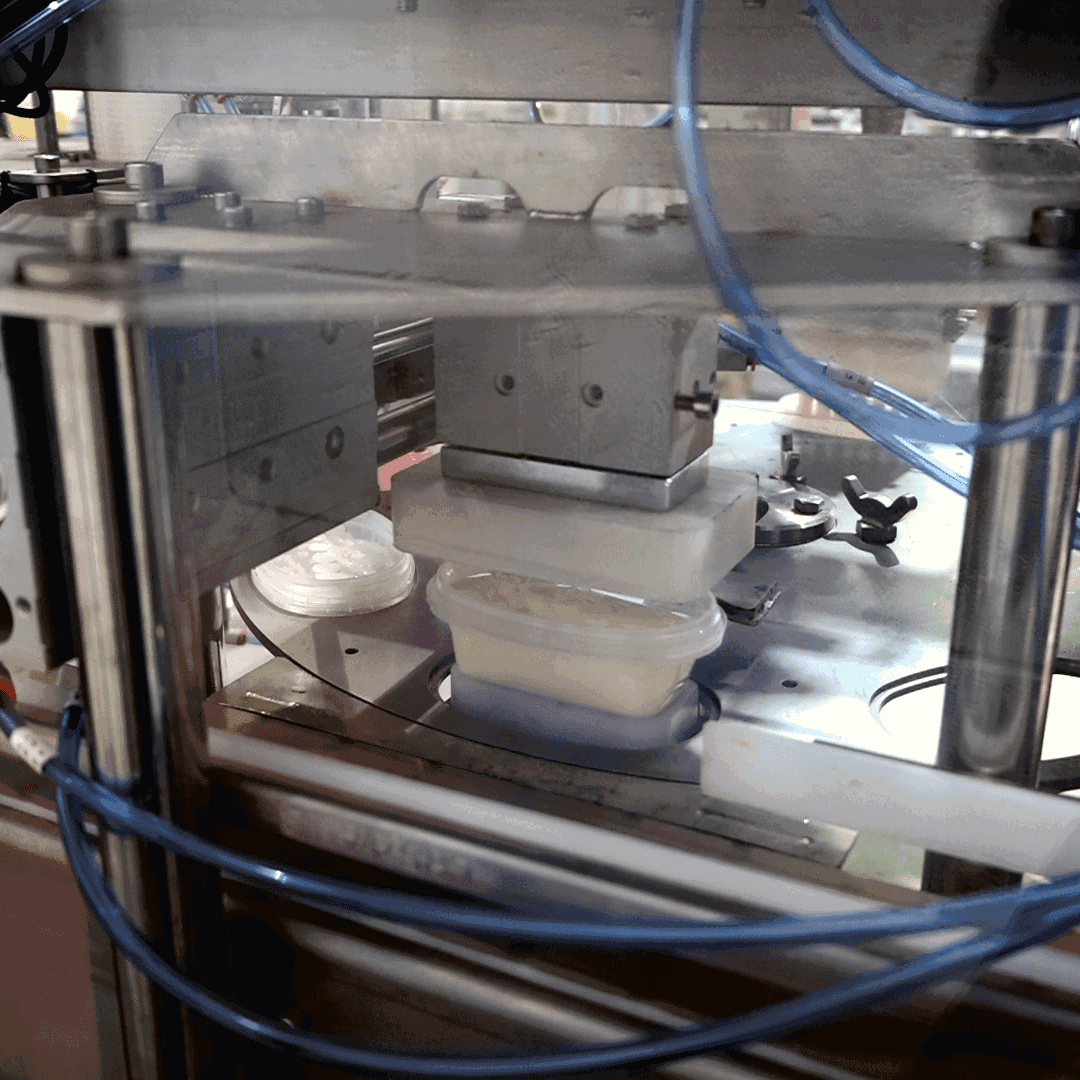

Filling and lid closing machine with product heating system

Processing equipment

This automatic machine is designed for filling and lid closing of butter and spreads products such as butter, margarine, spreads, fats, pastes, chocolate spreads, peanut butter etc., which must be preheated before filling and continuously stirred to maintain a uniform consistency and temperature. The product is heated in the feed hopper prior the filling. After product heating, it is filled into the containers indexed by the starwheel. The filled containers are moved to the lid closing station where the lid is placed on the container and pressed to it.