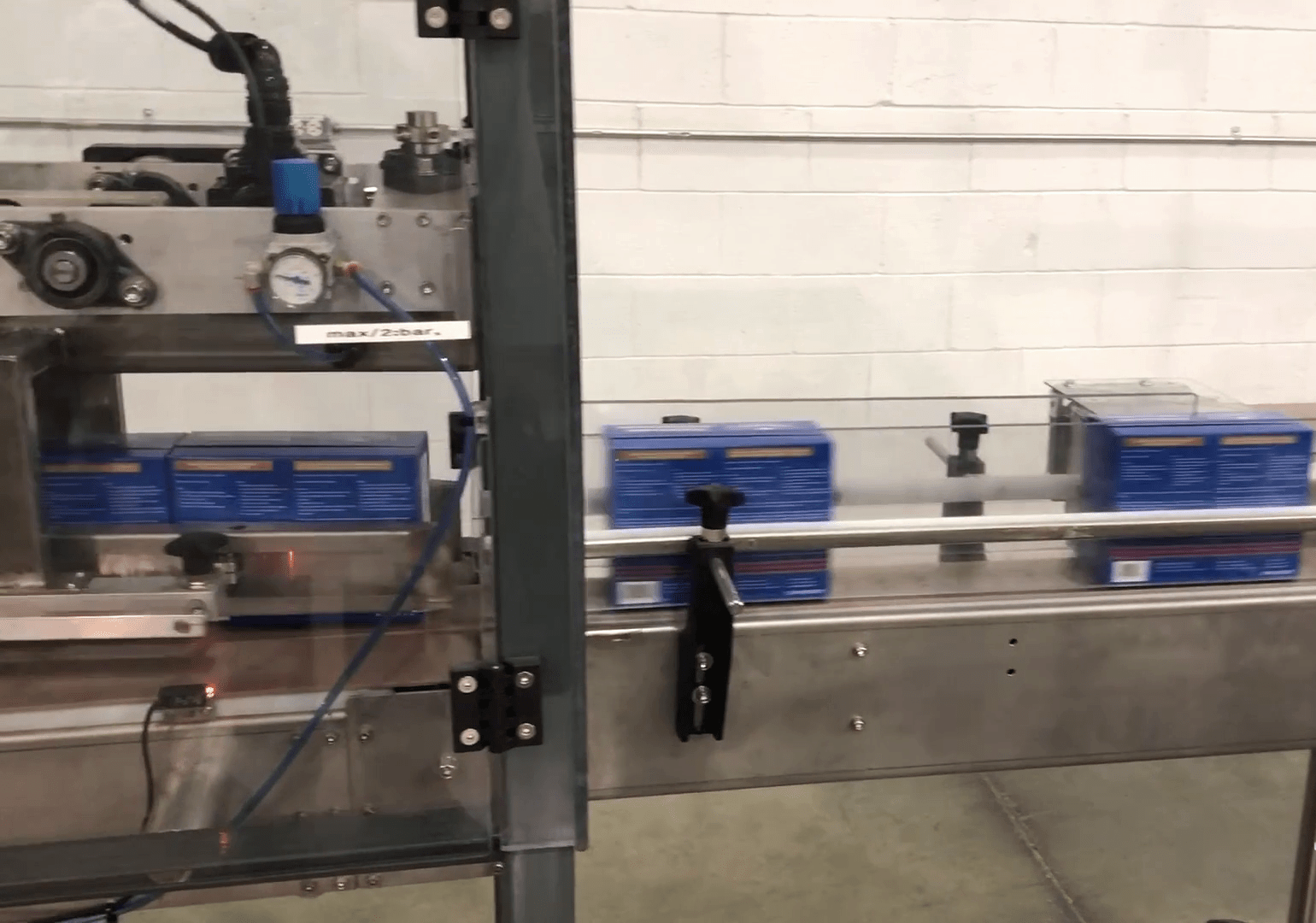

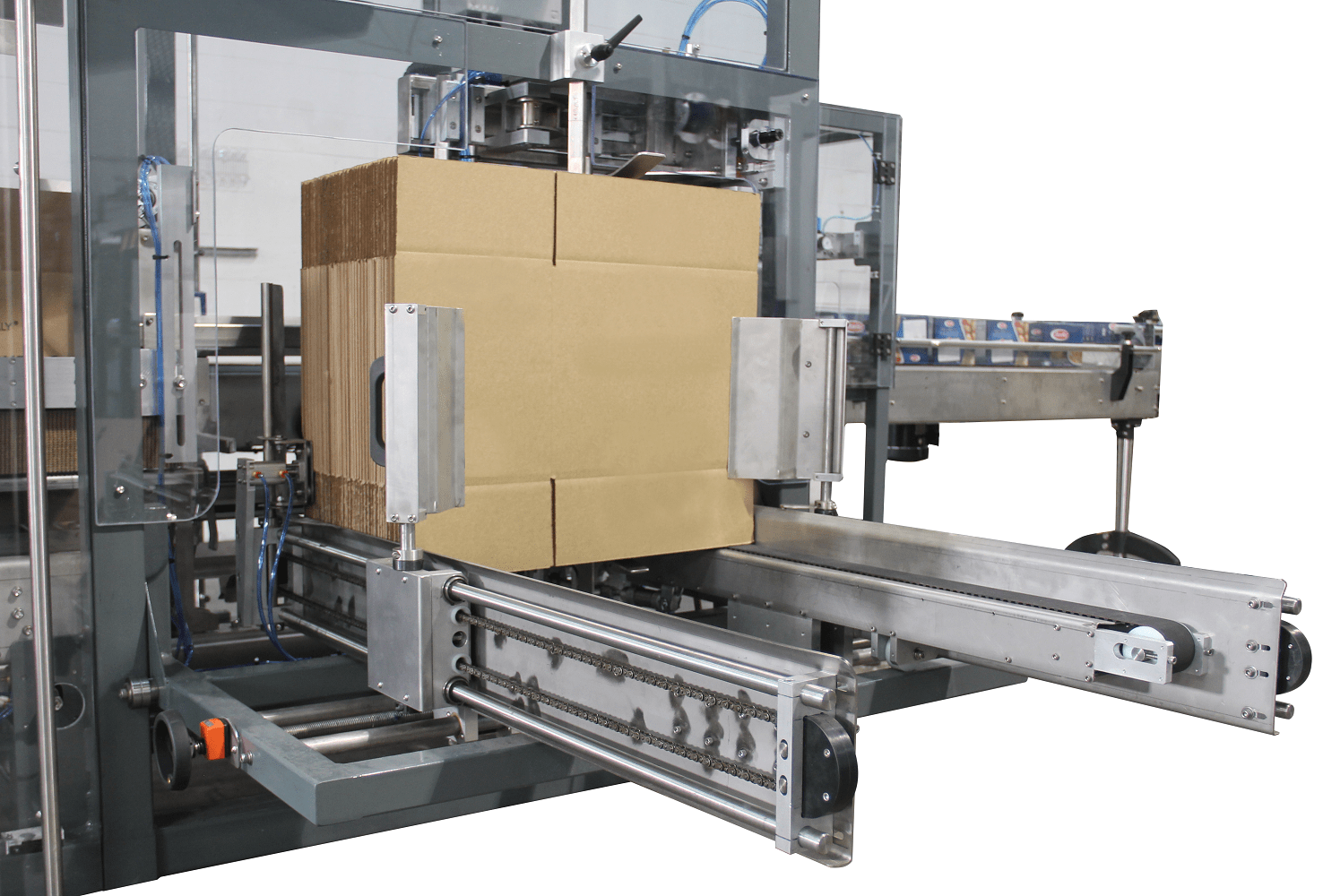

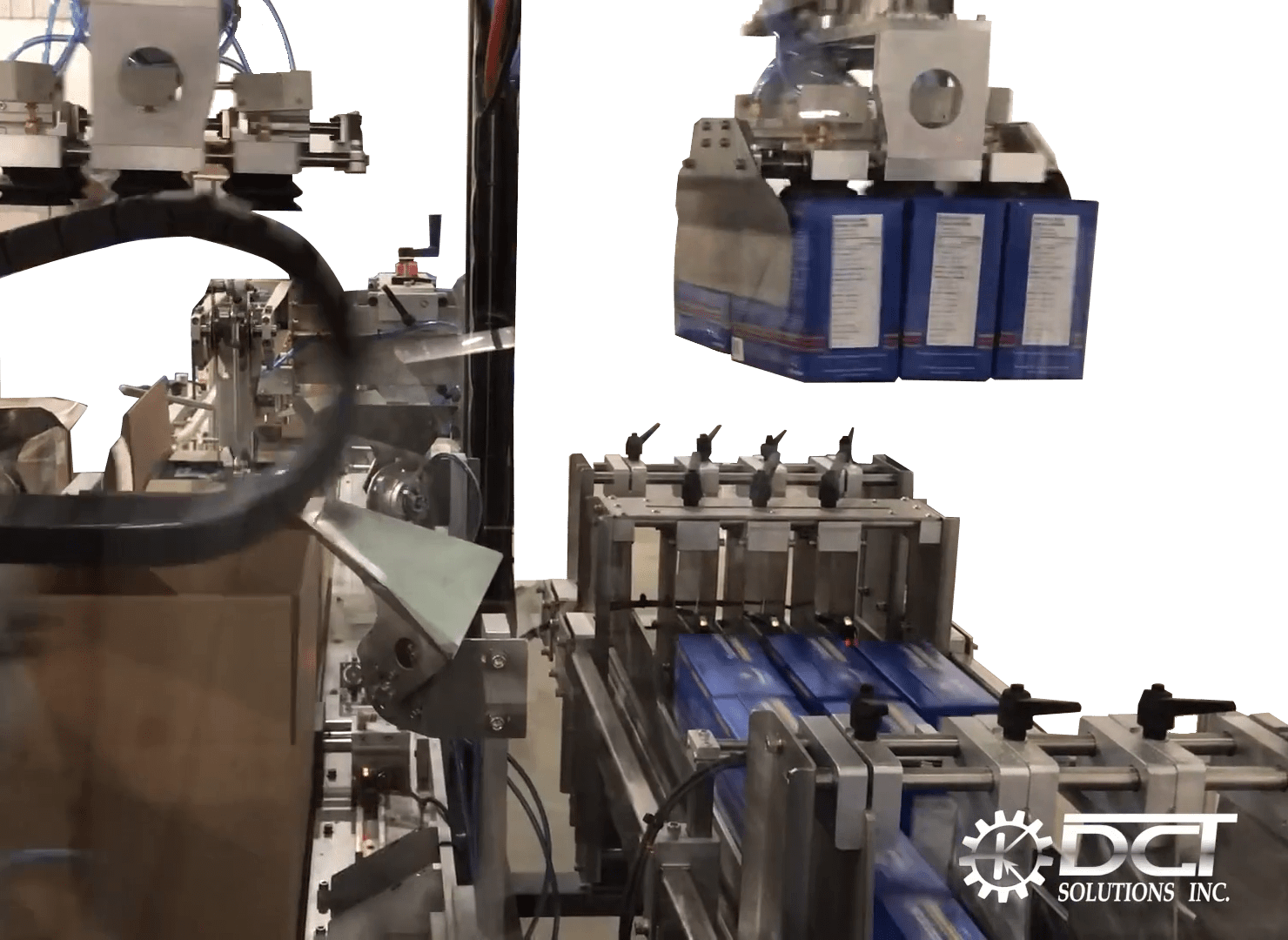

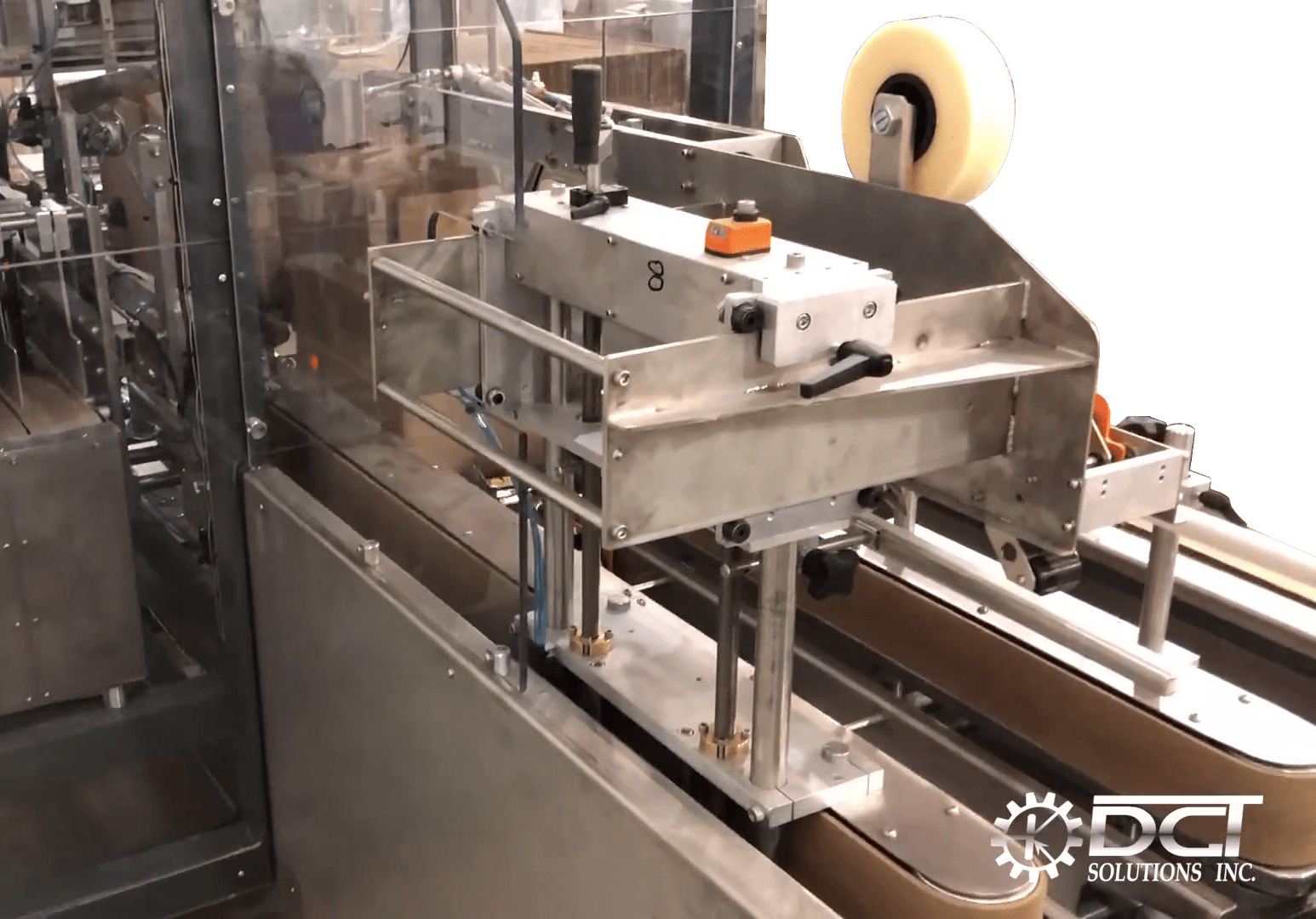

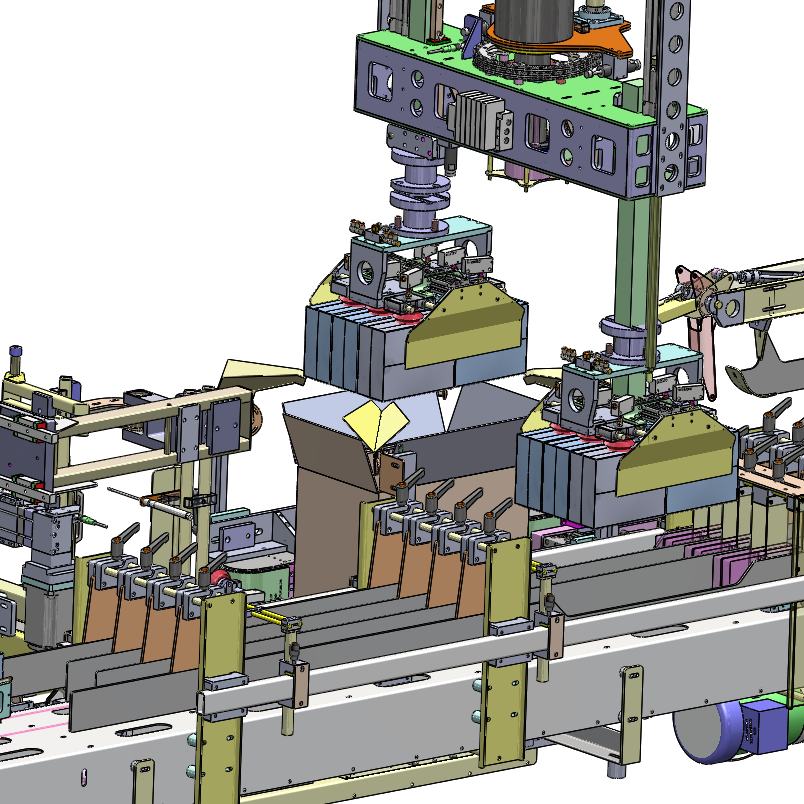

Automatic pick & place case packer for cartons

Packaging machines

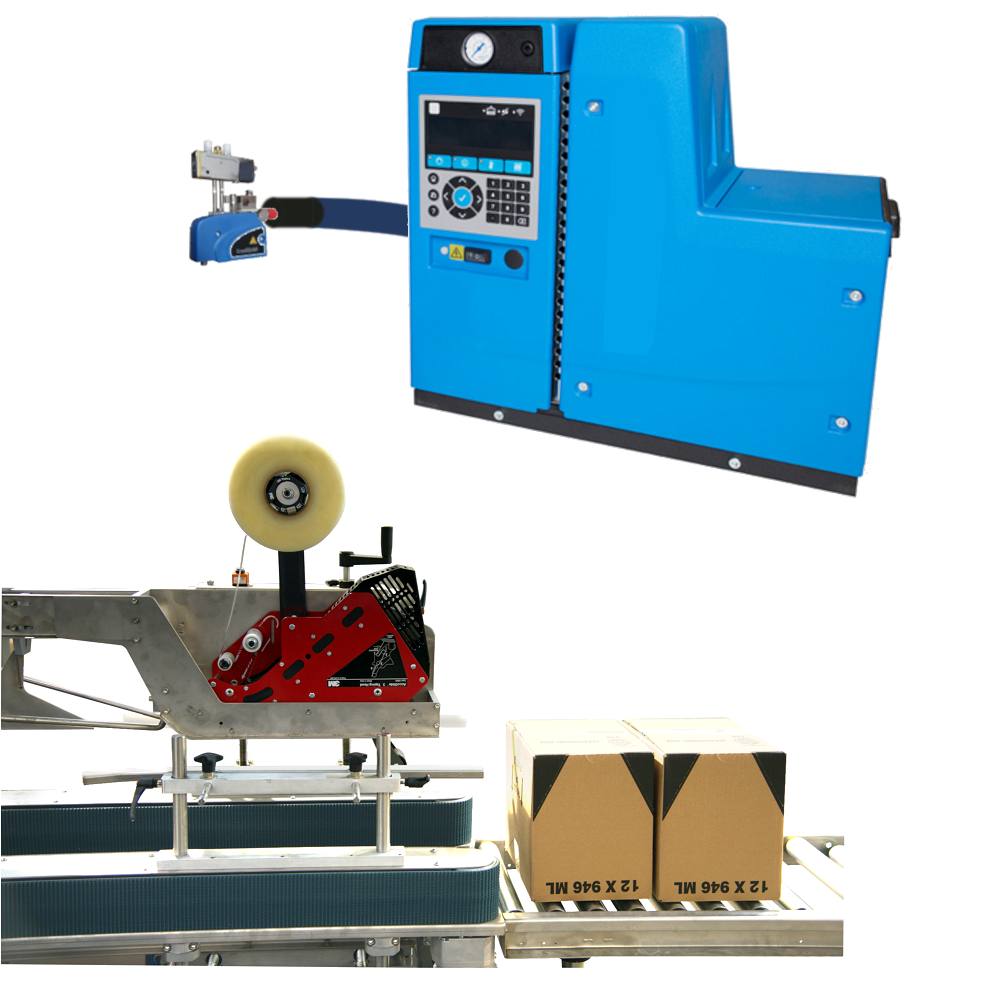

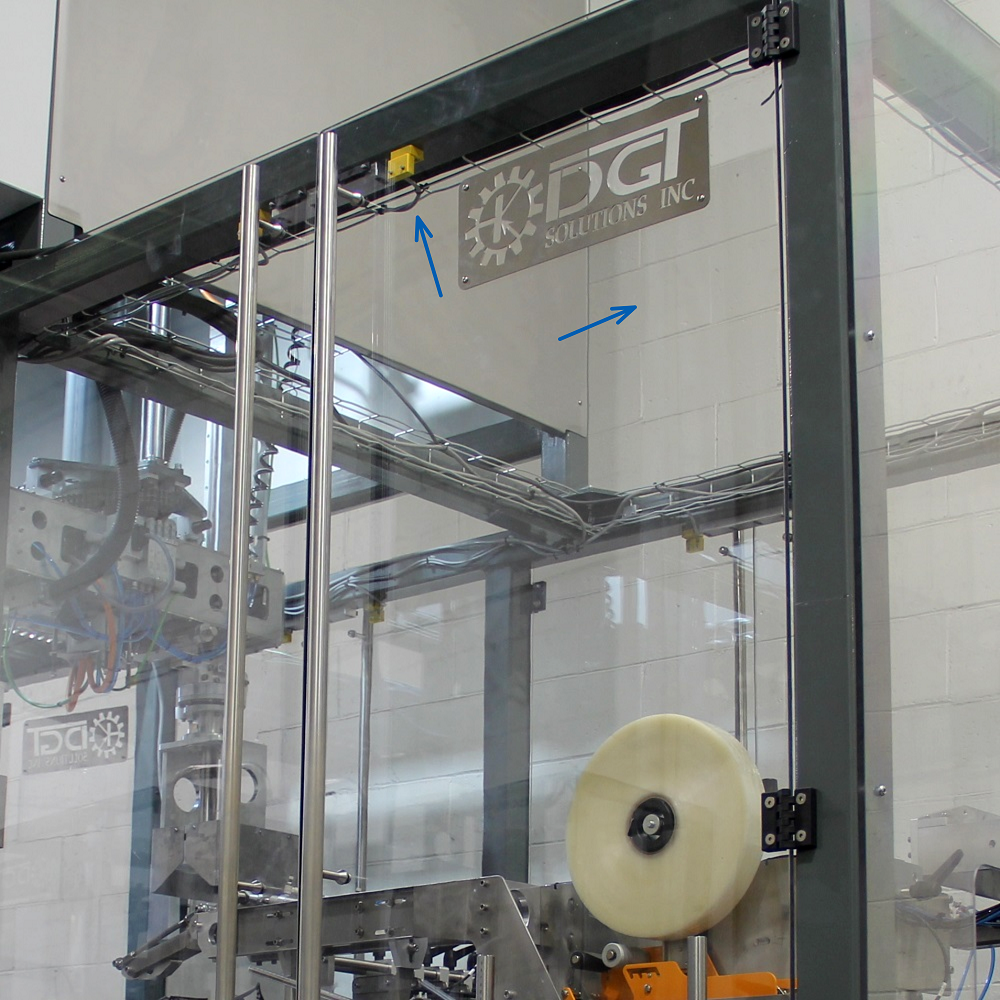

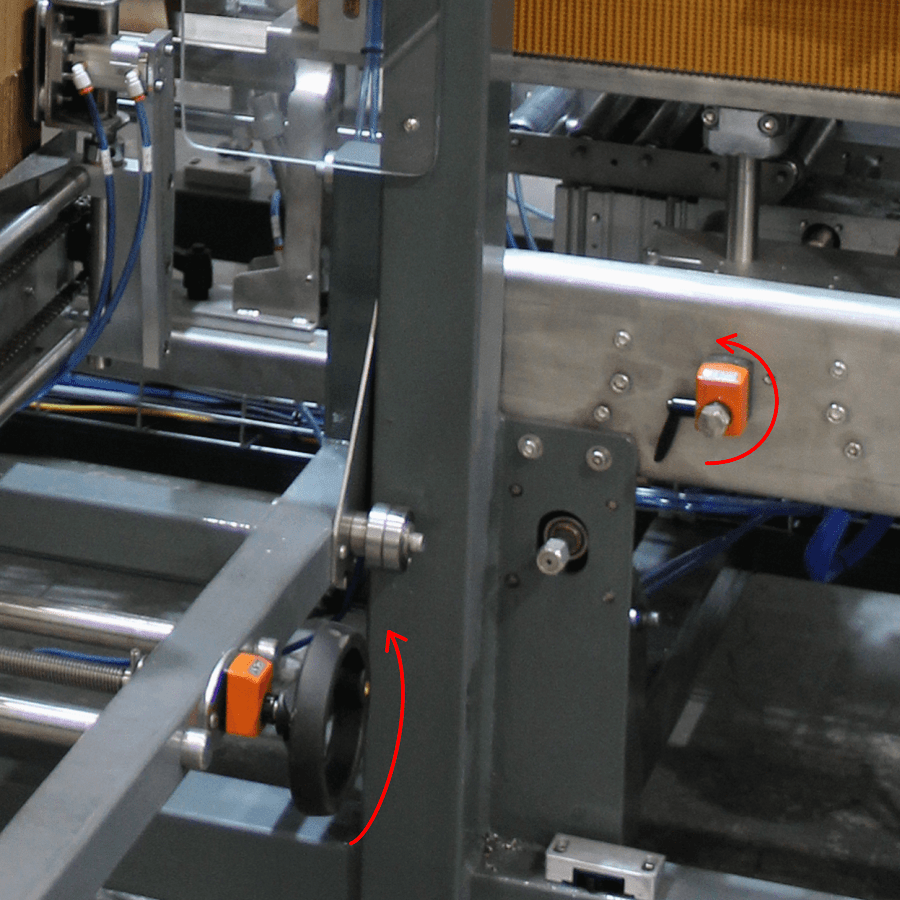

This case packer is made to individual specifications to perform packing of cartons into corrugated boxes or cases. The box forming and box sealing are integrated into the same machine. Picking and placing of the product is performed by rotary grippers. The grippers geometry matches the product shape to provide stable and secure gripping. The grippers can have different modifications according to different product sizes and shapes. The packed box is sealed with adhesive tape or hot glue.