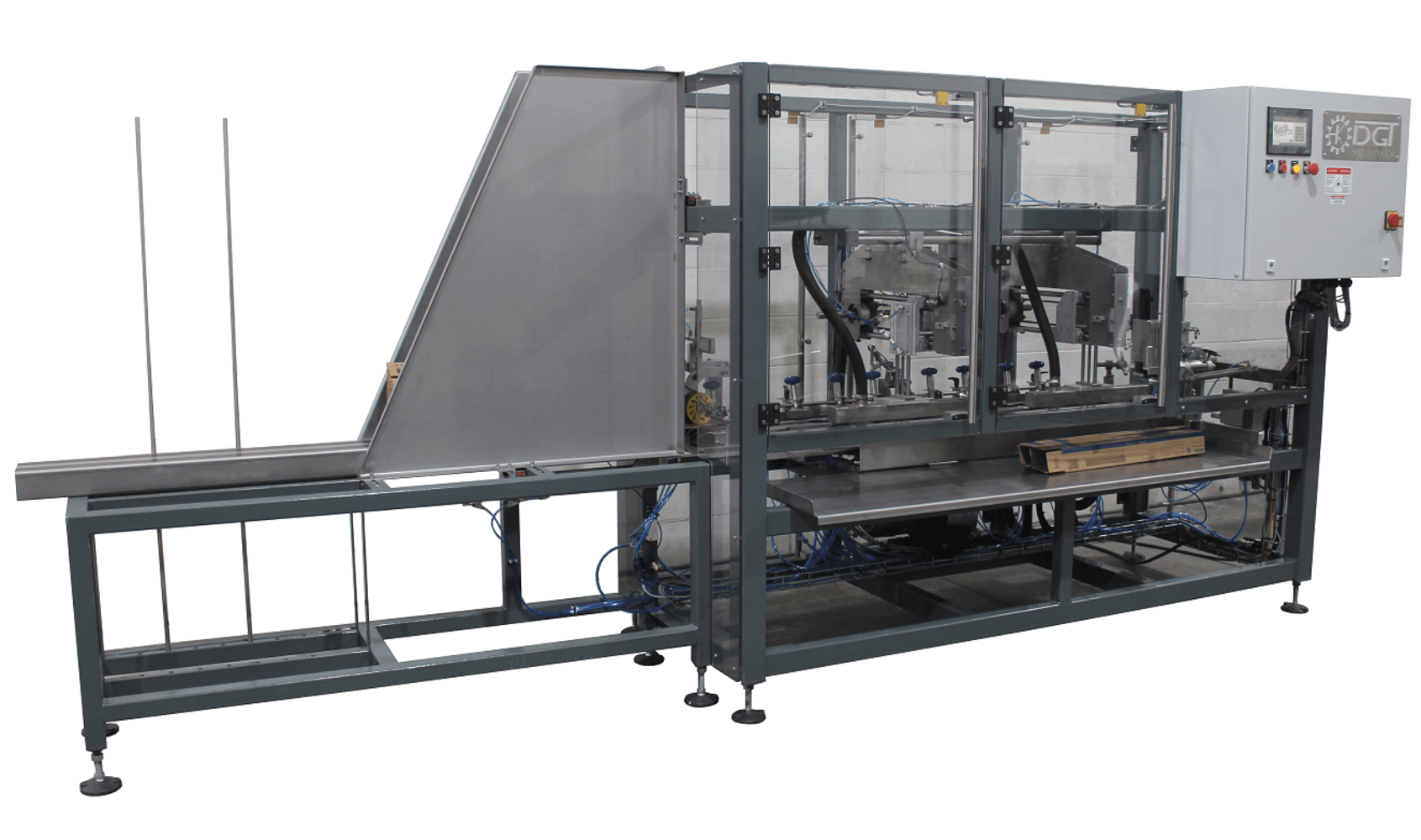

Cartoner for forming double-wall cartons with automatic bottom stapling

Packaging machines

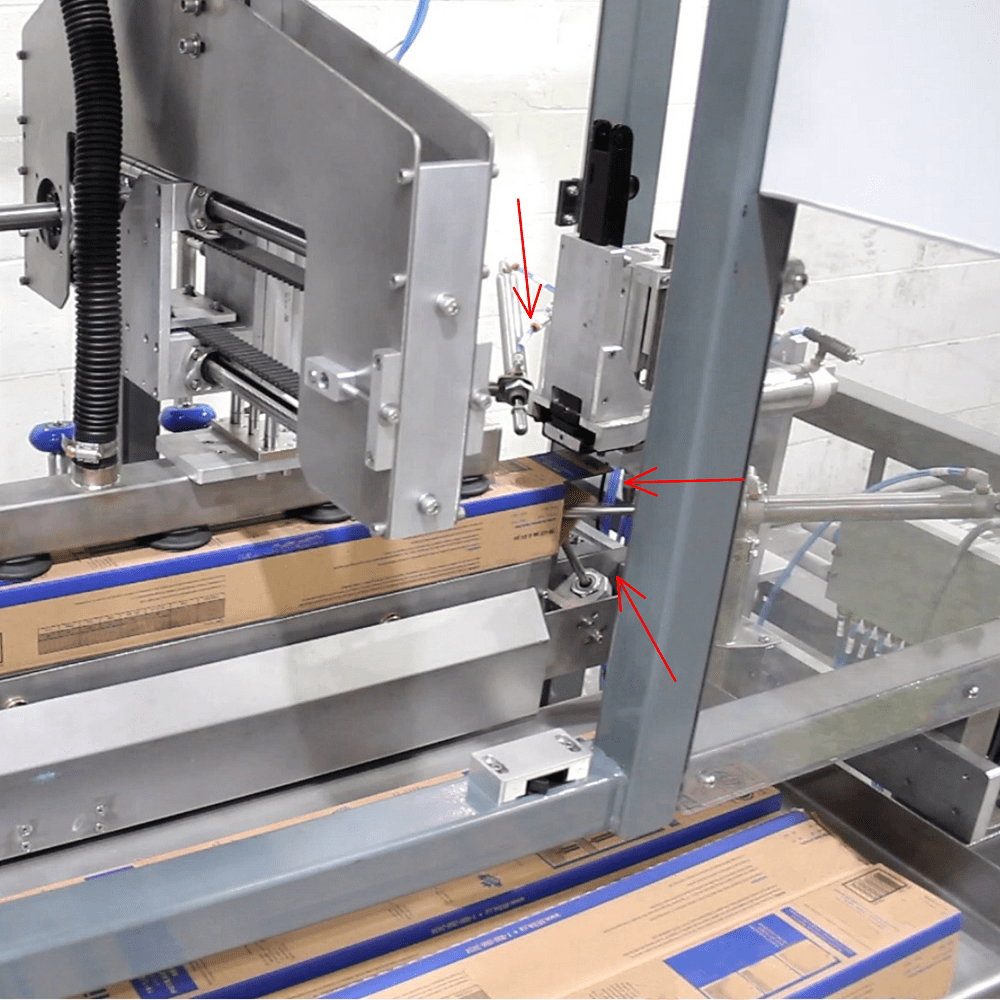

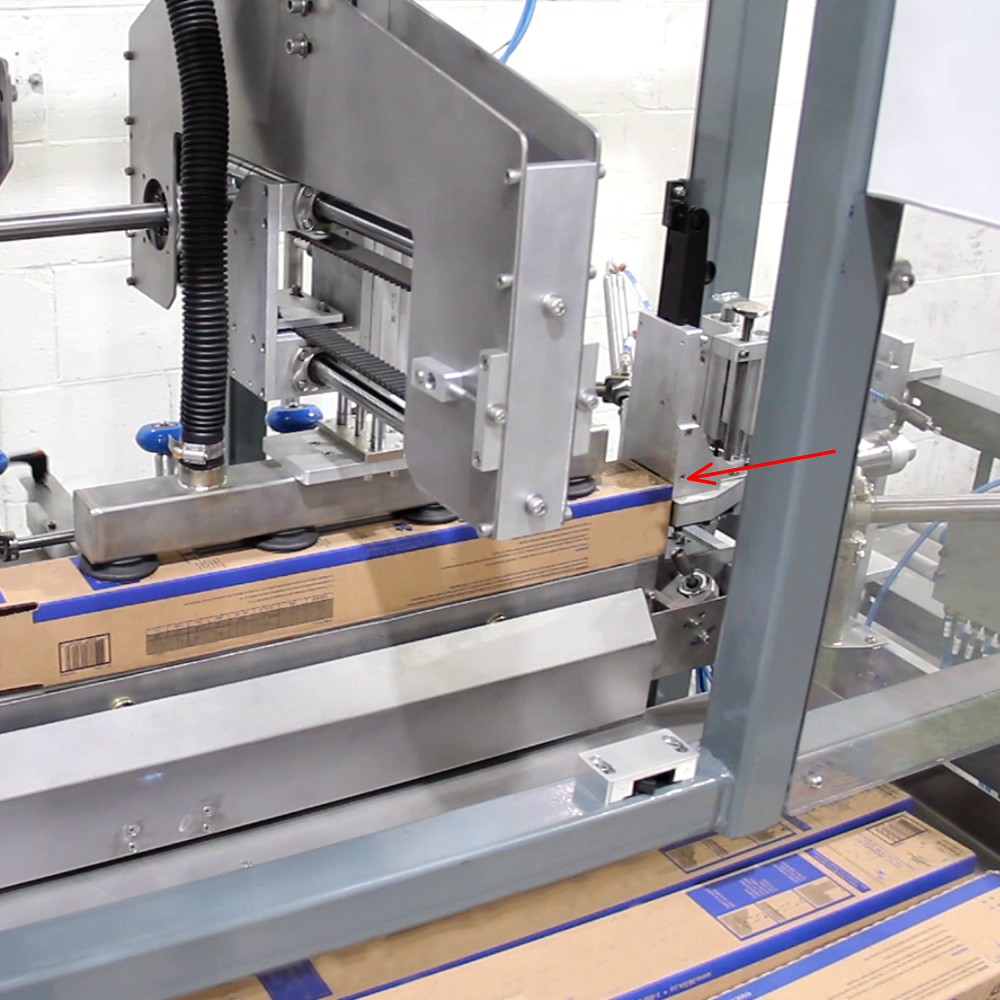

This cartoner is designed for the automatic assembling of double-wall cartons and their automatic bottom stapling. Double-wall cartons are stronger and can carry heavier weight and stapling them even more improves carton stackability and keeps better their shape.