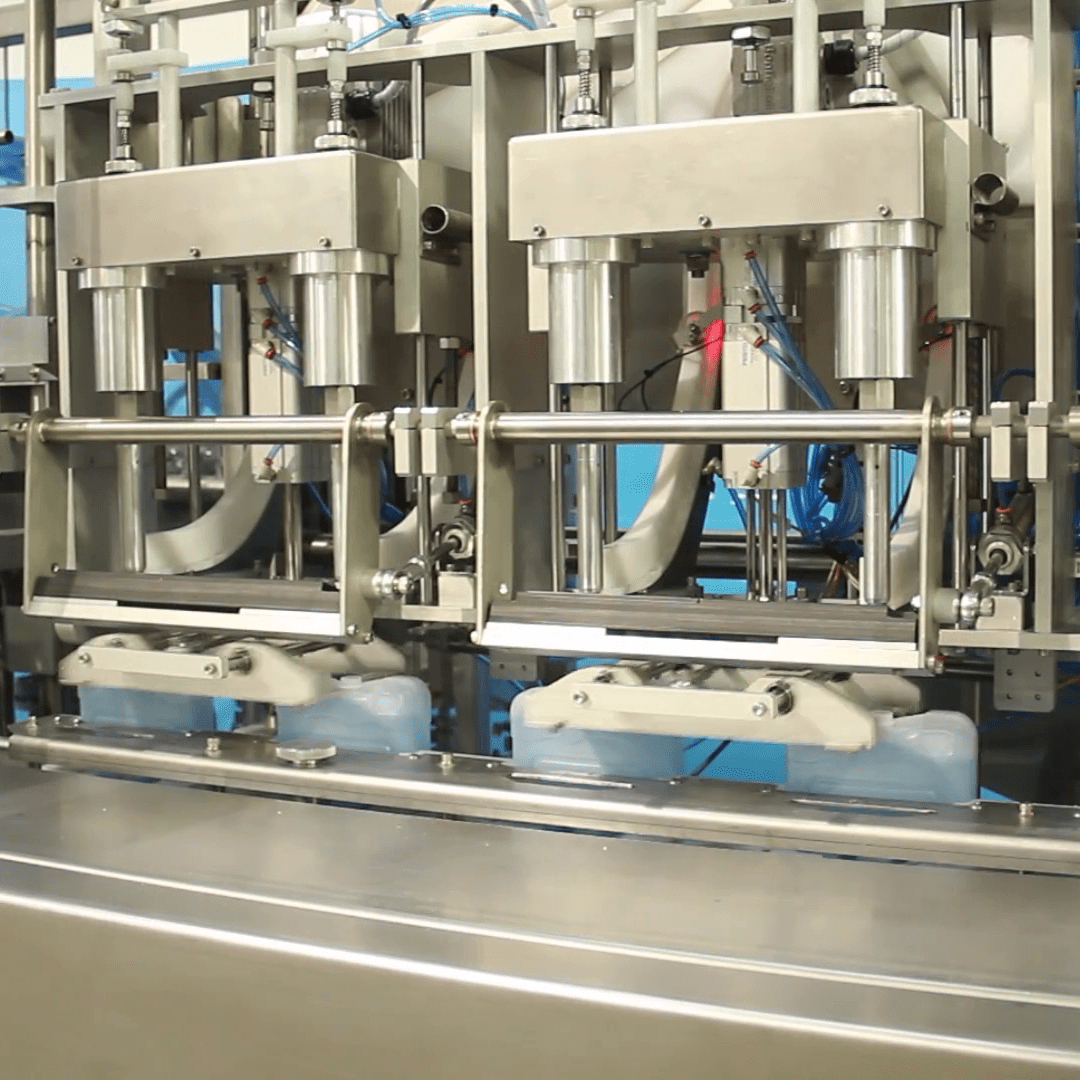

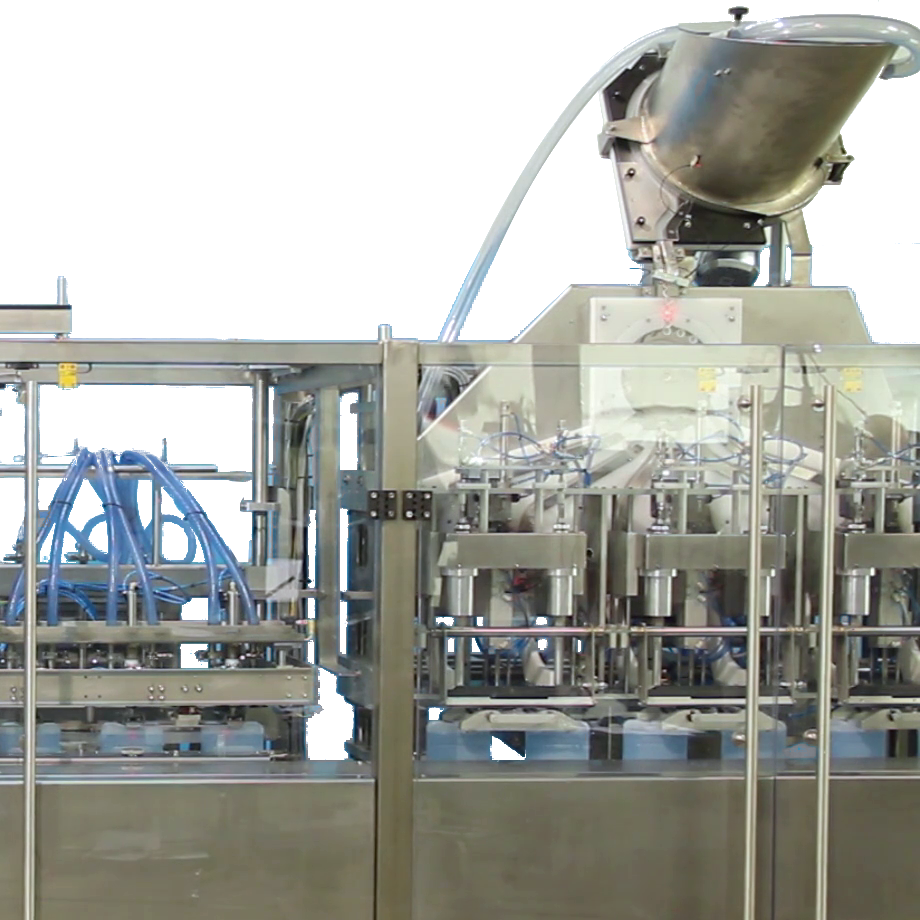

Automatic inline multi-head capping machine

Processing machines

This type of capping machine is designed to perform simultaneous inline capping of multiple containers. The caps are applied to the containers or inserted into them and tightened by spinning or torquing. In this particular machine shown as an example at the pictures, the capping heads are spinning during capping, melting the plastic neck of the container, so that the caps are melted into the container neck.

Request A Quote