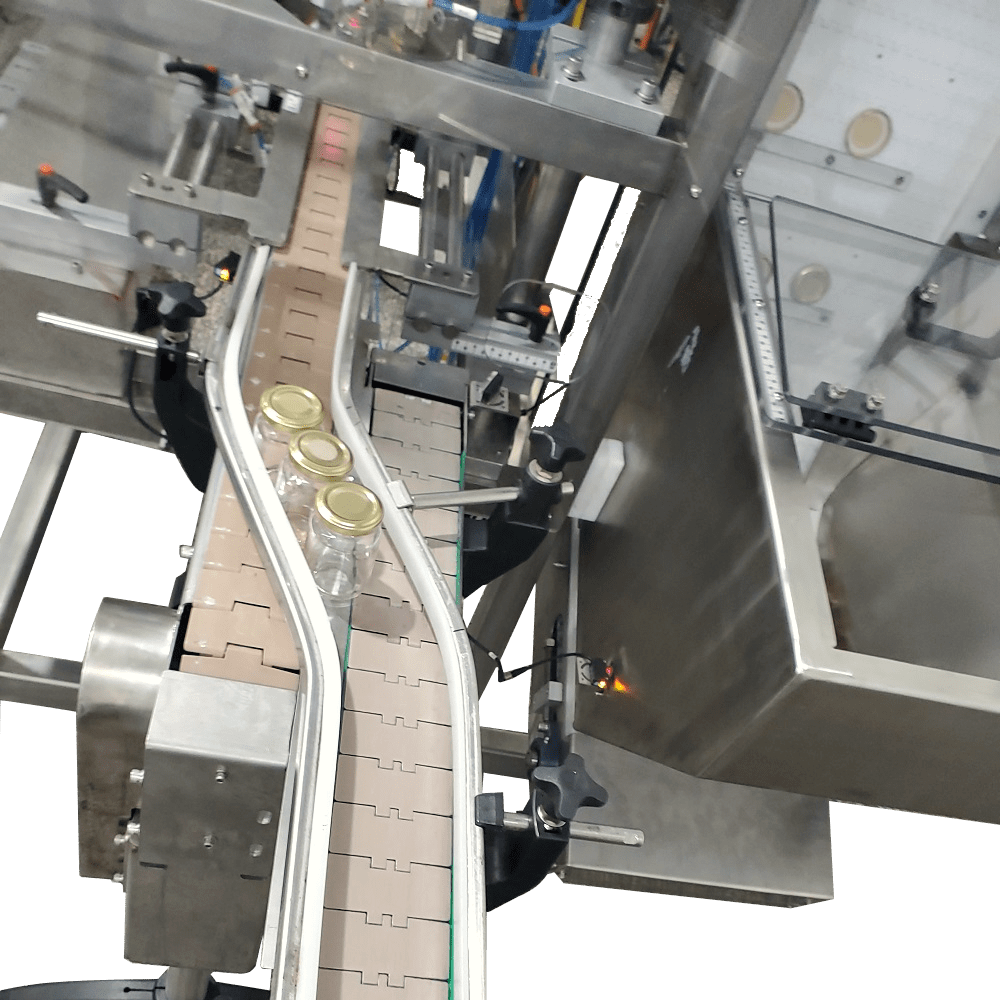

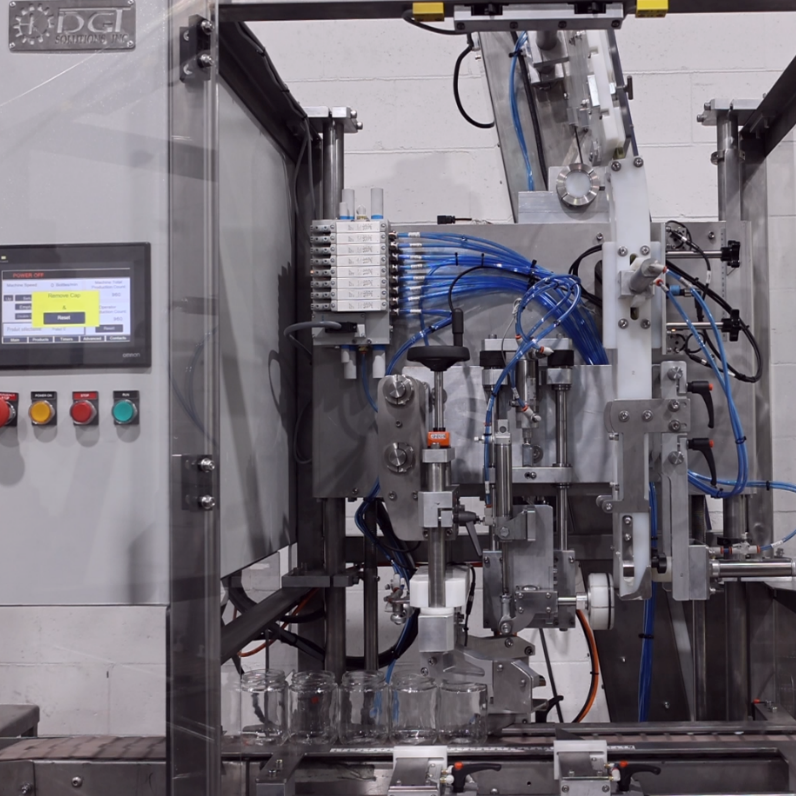

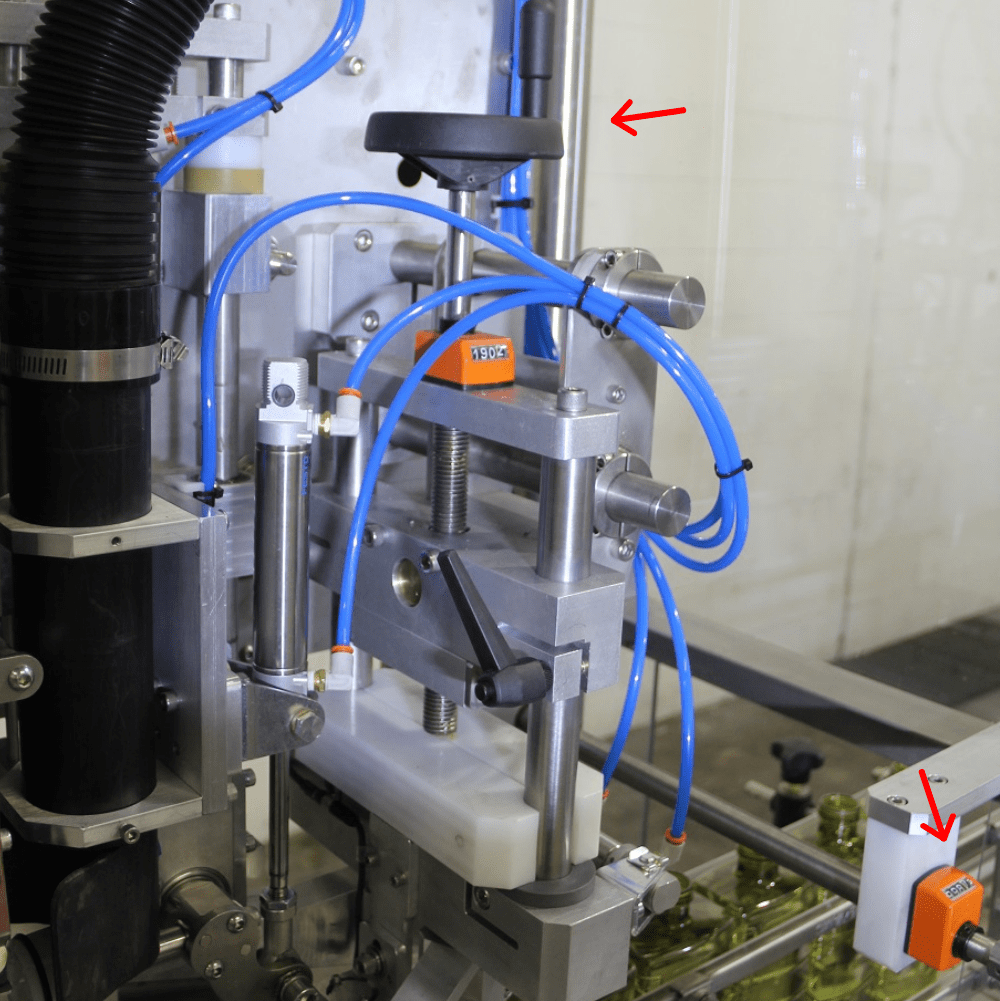

Automatic pick & place screw capping machine

Processing machines

This capping machine is designed to pick the screw-on caps aligned in the chute and torque them on top of the container to the required applied torque securely tightening it.

Request A Quote