Automatic rotary capping machine

Processing machines

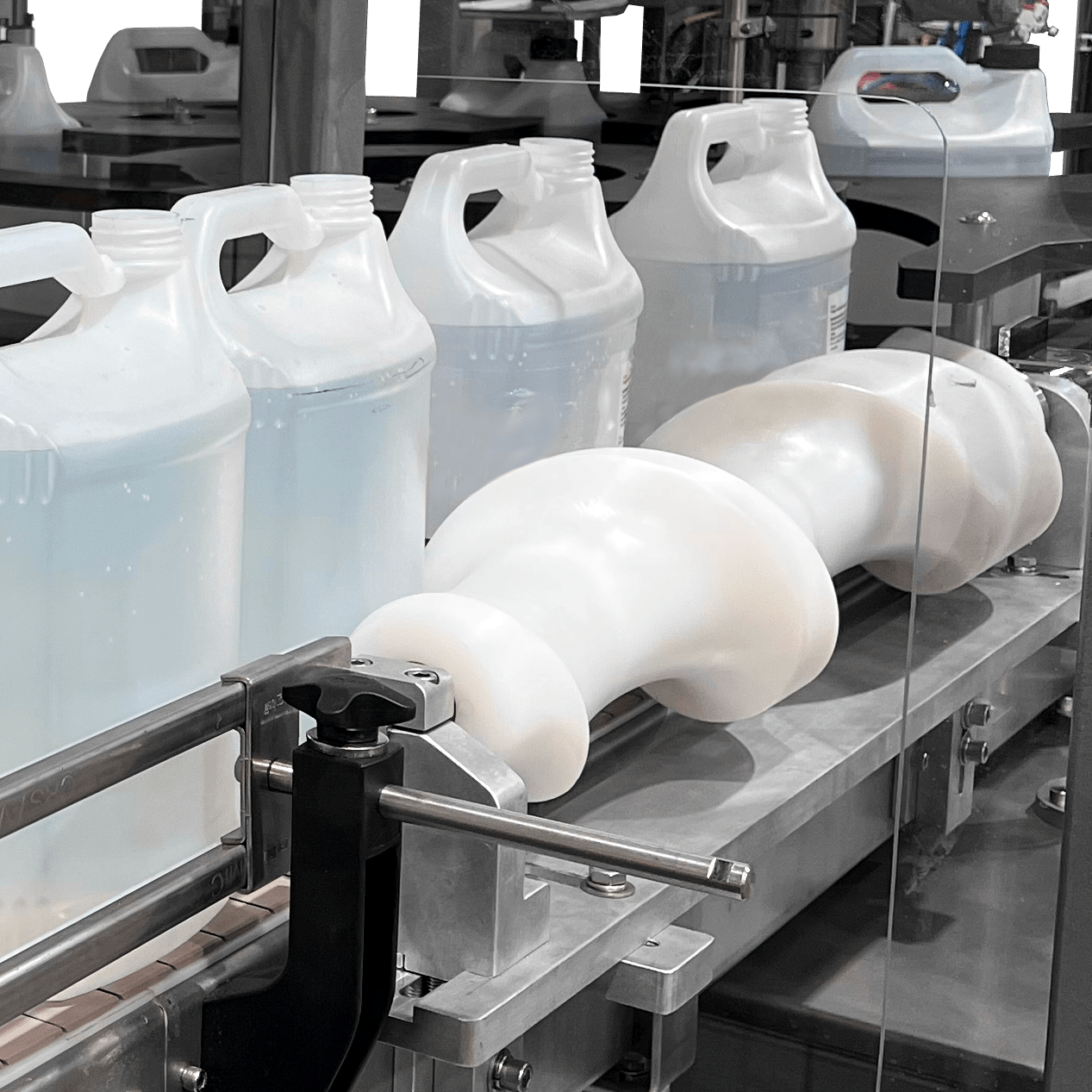

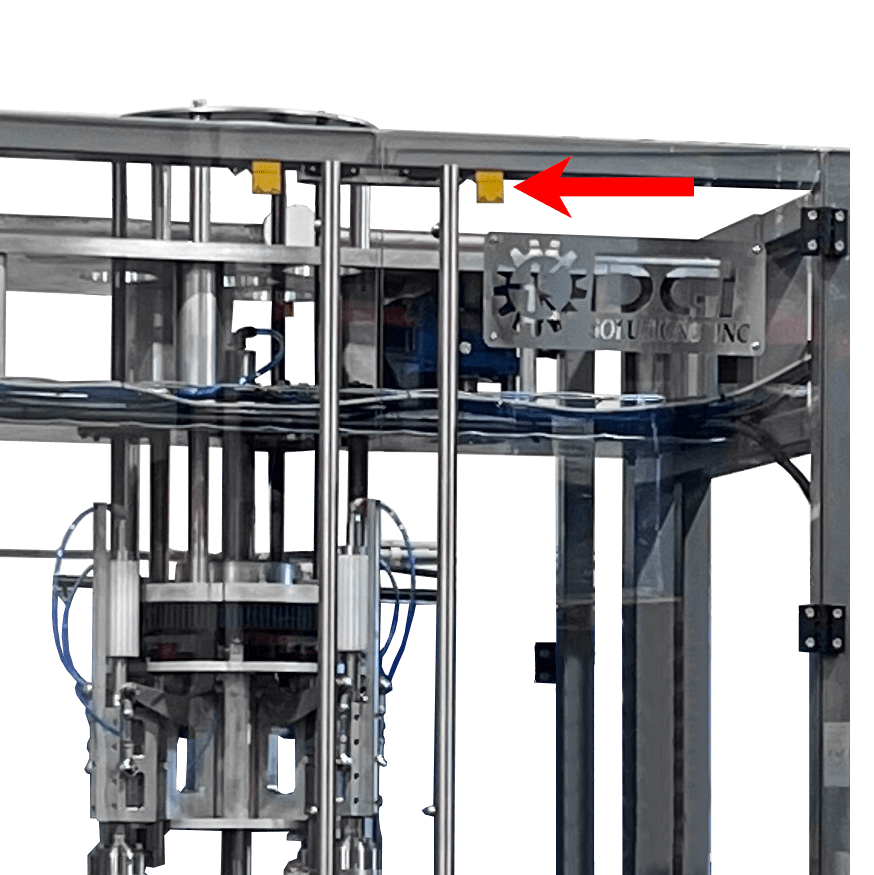

An automatic rotary capping machine is a solution for a quick and efficient capping that can be customized to a specific container type, shape, and size. In this type of machine, the containers are moved around capping stations, where specially designed capping grippers place caps onto the container necks.

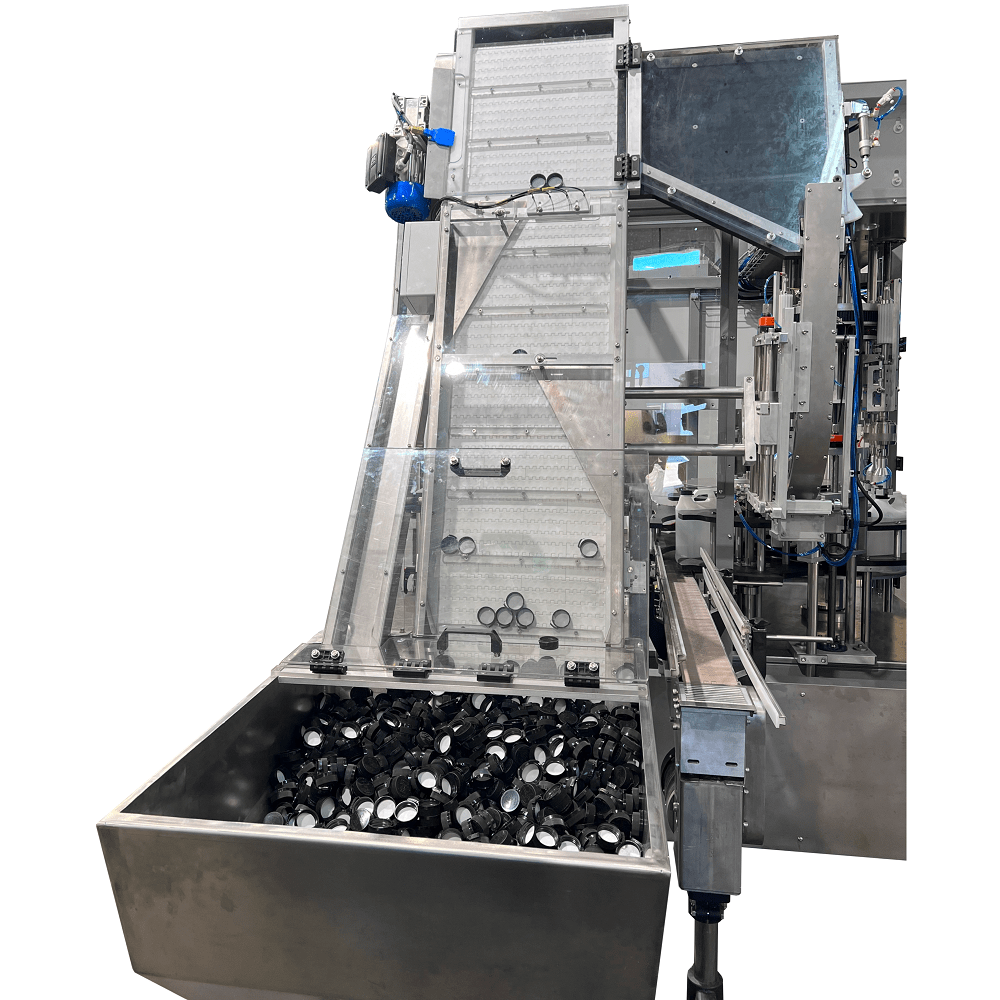

An automatic rotary capping machine is made to individual specifications to perform feeding, orienting, and applying caps or lids to the bottles or containers.

Custom-made cappers ensure that your containers or bottles will be capped and torqued consistently. They have great flexibility with their electronically controlled, easily configurable, adjustable, parameters for rotation, twisting force, and container height.

Request A Quote