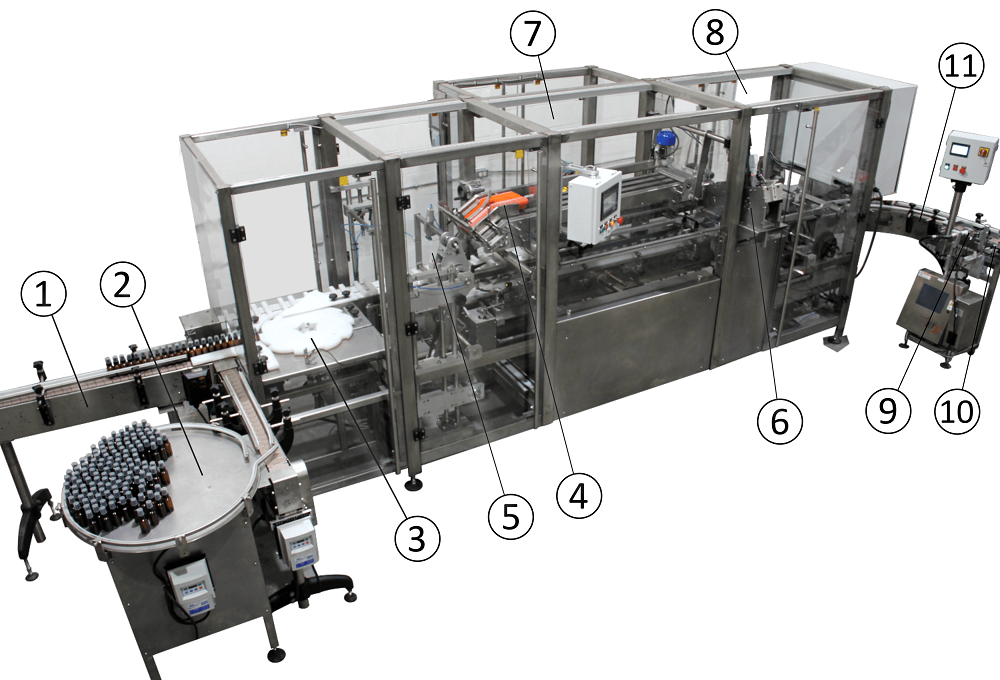

Automatic robotic cartoner machine for loading several different products

Packaging machines

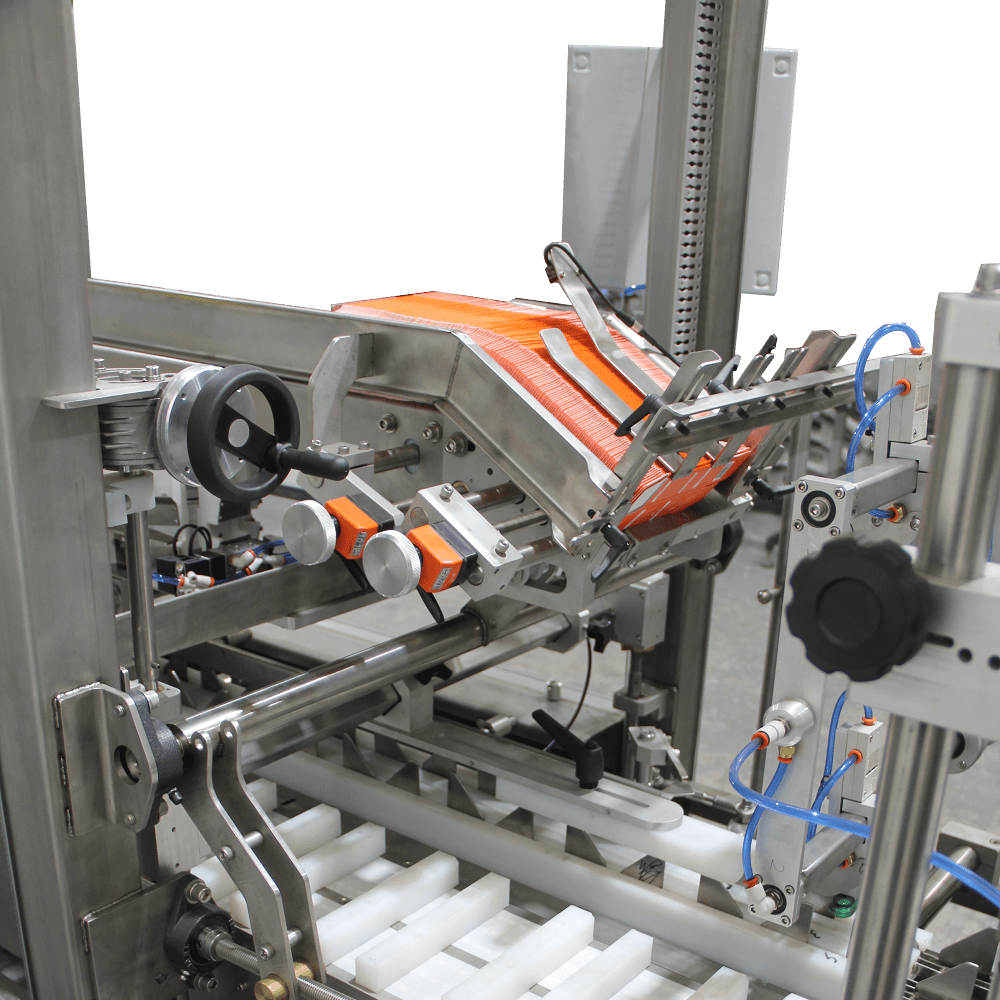

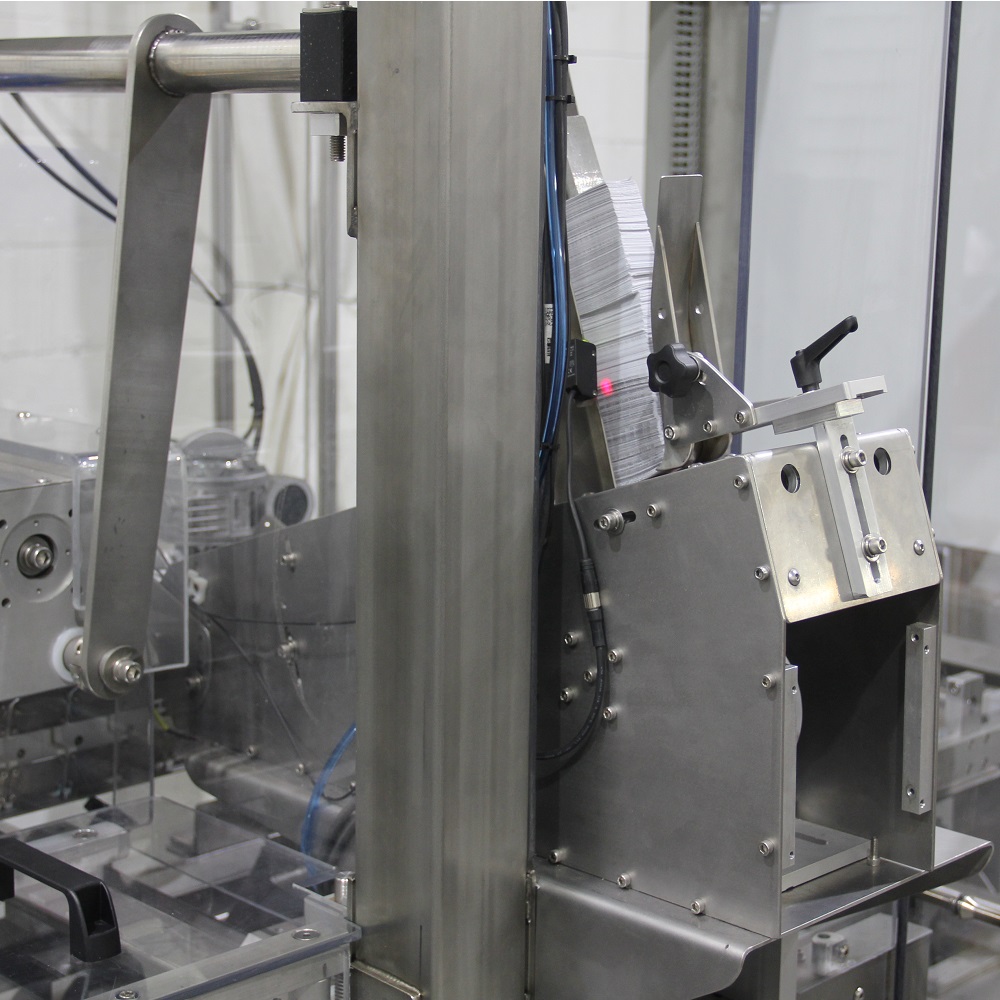

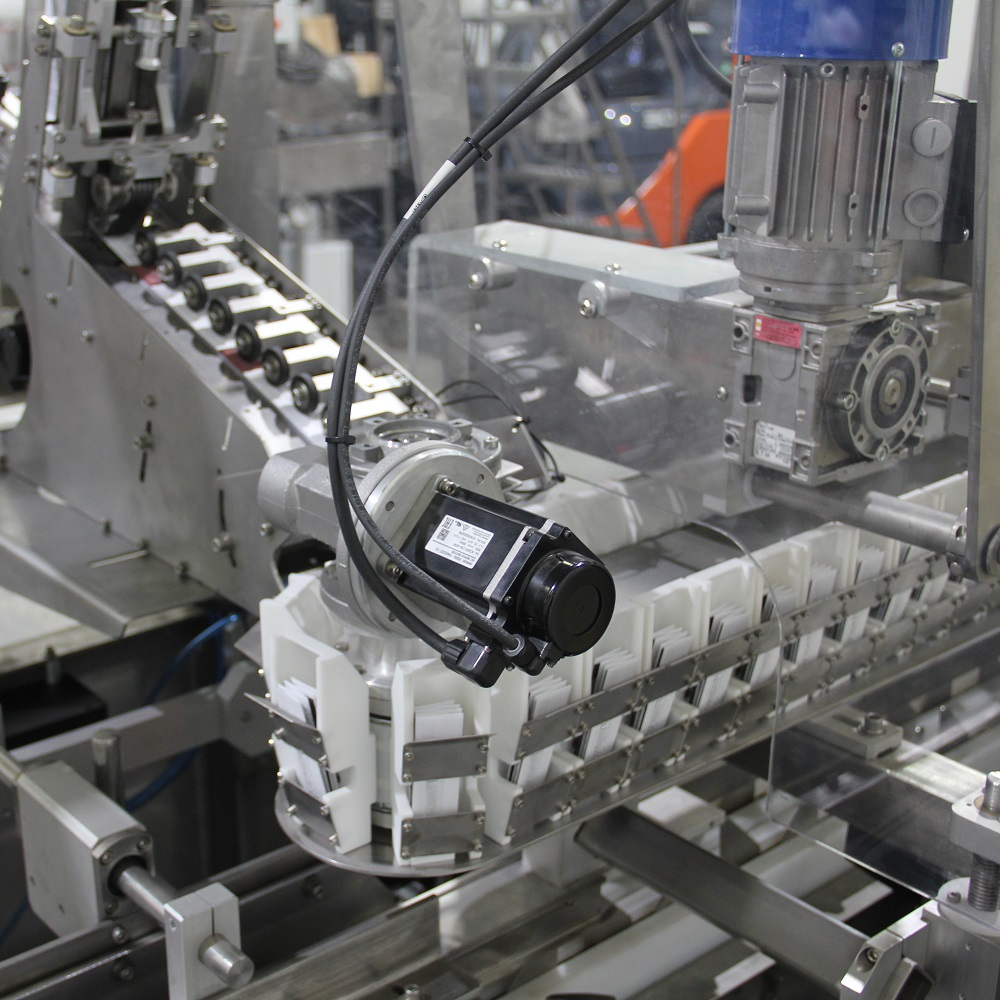

This machine is designed to perform carton pre-forming, several different products loading into pre-formed cartons, followed by carton closing. The machine is equipped with container star-wheel indexing bottles and changing their orientation from vertical to horizontal to enable loading them into horizontally fed pre-formed cartons. The pamphlets or leaflets are fed to the loading section with a pamphlet feeder and pamphlet distributors. In addition, this cartoner is equipped with a printing system for printing product information on the filled carton.